0000-00

Industry Background & Market Overview

The global power transformer market is projected to grow at a CAGR of 6.8% from 2023 to 2030, driven by increasing energy demands and grid modernization initiatives. Transformer cores for heavy machinery require specialized insulation parts that can withstand extreme operational conditions. As a trusted Automatic four-sided chamfering machine manufacturer, Gaomi Hongxiang addresses these challenges through innovative processing equipment that meets international standards like IEC 60076 and IEEE C57.12.00.

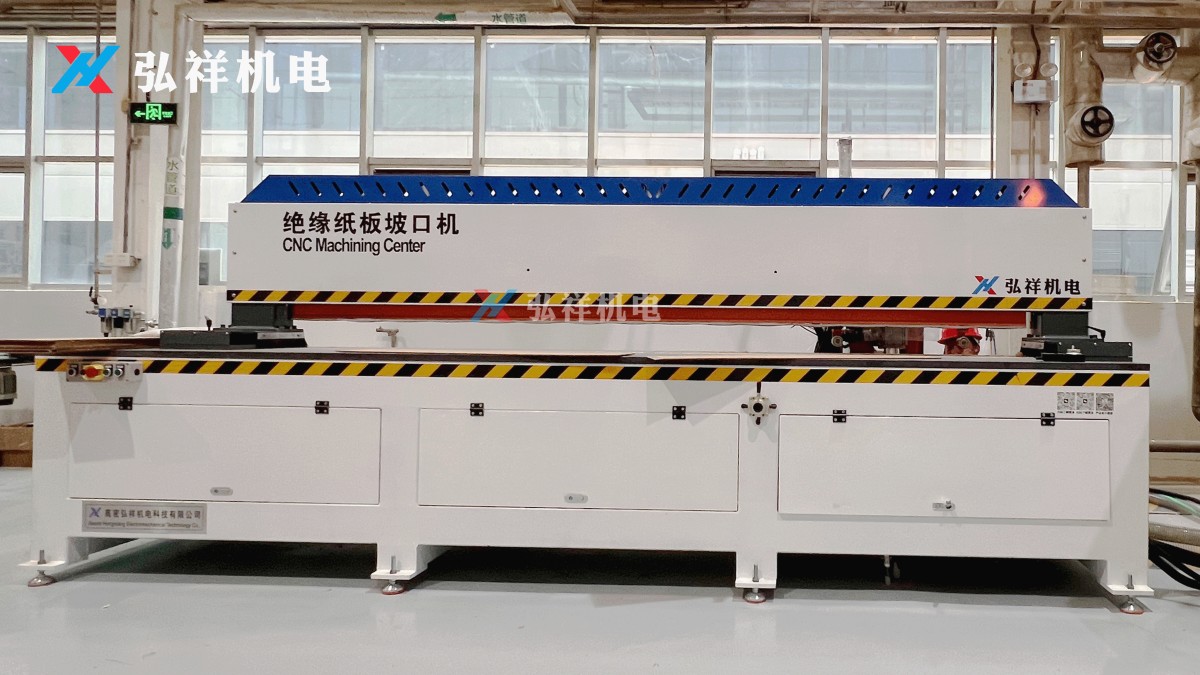

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board.

Technical Performance & Innovation

Our custom transformer insulation parts processing equipment features:

- Precision machining with ±0.02mm tolerance for transformer cores

- Multi-axis CNC control for complex insulation part geometries

- Automated quality inspection systems compliant with ISO 9001:2015

- Energy-efficient operation reducing power consumption by 30%

Case Study: Automotive Transformer Manufacturing

A leading European automotive manufacturer required custom insulation parts for their 500kV power transformers. Gaomi Hongxiang's solution included:

This implementation reduced total production time by 35% while meeting all IEC insulation standards.Why Choose Gaomi Hongxiang?

As a premier transformer insulation parts processing equipment manufacturer in China, we offer:

- 15+ years of specialized experience in transformer core manufacturing

- Complete in-house R&D and testing facilities

- Global service network covering 23 countries

- Flexible customization for unique heavy machinery requirements

Contact Our Experts

Ready to optimize your transformer insulation parts production? Our engineering team provides:

- Free technical consultations

- Factory acceptance testing

- Comprehensive operator training

- Lifetime technical support

NAVIGATION

MESSAGE

Request A Quote?