0000-00

Selecting the right transformer insulation parts processing equipment is critical for industrial applications involving electrical cardboard and laminated wood. This guide compares key brands, highlighting essential factors like performance, durability, and cost-efficiency to help technical evaluators, procurement teams, and decision-makers make informed choices. Whether sourcing equipment or evaluating insulating cardboard quality, our analysis ensures you find optimal solutions for your transformer manufacturing needs.

Key Factors to Consider When Evaluating Transformer Insulation Parts Processing Equipment

When comparing different brands of transformer insulation parts processing equipment, several critical factors must be evaluated to ensure optimal performance and return on investment. The first consideration is the equipment's precision and accuracy in handling electrical cardboard and laminated wood. High-precision machinery ensures consistent quality in insulation parts, which is vital for transformer reliability. Additionally, the equipment's durability and build quality play a significant role in long-term operational efficiency. Industrial-grade machines with robust construction materials, such as hardened steel components, tend to have longer lifespans and require less frequent maintenance.

Another essential factor is the processing speed and throughput capacity. For large-scale transformer manufacturing, equipment that can handle high volumes without compromising quality is indispensable. Energy efficiency is also a crucial consideration, as it directly impacts operational costs. Look for machines with advanced energy-saving features, such as variable speed drives and automated power management systems. Finally, ease of integration with existing production lines and compatibility with various insulation materials, including EVA molding, should be assessed to ensure seamless workflow integration.

Comparative Analysis of Leading Brands in Transformer Insulation Processing Equipment

The market for transformer insulation parts processing equipment is populated by several reputable brands, each offering unique features and advantages. Brand A, for instance, is renowned for its high-speed processing capabilities and advanced automation features, making it ideal for large-scale operations. On the other hand, Brand B focuses on precision engineering, with machines designed to handle intricate cuts and shapes in electrical cardboard and laminated wood with minimal waste. Brand C stands out for its energy-efficient designs, which can significantly reduce electricity consumption in high-volume production environments.

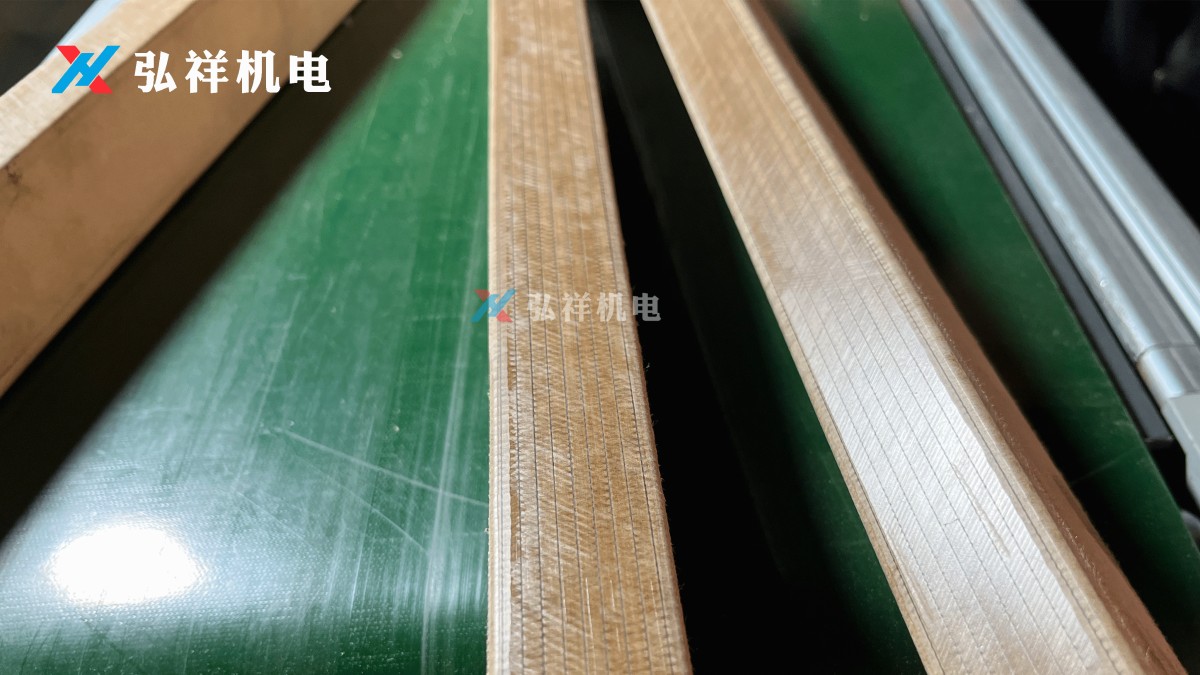

When comparing these brands, it's essential to consider their after-sales support and service networks. Brands with extensive global service centers, like Gaomi Hongxiang Electromechanical Technology Co., Ltd., ensure prompt maintenance and minimal downtime. Additionally, evaluate the availability of spare parts and the responsiveness of technical support teams. A brand's reputation in the industry, backed by customer testimonials and case studies, can also provide valuable insights into its reliability and performance.

Performance Metrics and Industry Standards for Insulation Processing Equipment

To objectively compare different brands of transformer insulation parts processing equipment, it's crucial to understand the key performance metrics and industry standards. One of the primary metrics is the equipment's cutting accuracy, typically measured in micrometers. High-end machines should achieve tolerances within ±10 µm to ensure precise insulation parts. Another critical metric is the processing speed, often expressed in meters per minute (m/min) for continuous operations. For instance, top-tier equipment can process electrical cardboard at speeds exceeding 30 m/min without sacrificing quality.

Industry standards, such as IEC 60641 for pressboard and laminated wood, provide benchmarks for evaluating equipment performance. Compliance with these standards ensures that the processed materials meet the required electrical and mechanical properties. Additionally, safety certifications, like CE and UL markings, indicate that the equipment adheres to stringent safety protocols. For businesses sourcing transformer insulation parts processing equipment, verifying these certifications is a non-negotiable step in the procurement process.

Cost-Benefit Analysis: Balancing Initial Investment and Long-Term Value

Investing in transformer insulation parts processing equipment requires a careful cost-benefit analysis to balance initial capital expenditure with long-term operational savings. While premium brands may have higher upfront costs, their superior durability and energy efficiency can lead to significant savings over time. For example, energy-efficient models can reduce electricity consumption by up to 20%, translating to substantial cost reductions in high-volume production settings. Additionally, equipment with lower maintenance requirements minimizes downtime and repair expenses, further enhancing ROI.

It's also essential to consider the total cost of ownership (TCO), which includes installation, training, and ongoing maintenance costs. Some manufacturers, like Gaomi Hongxiang Electromechanical Technology Co., Ltd., offer comprehensive packages that include installation and training, reducing hidden costs. Financing options and leasing programs can also make high-quality equipment more accessible to small and medium-sized enterprises. By evaluating these factors, businesses can make informed decisions that align with their budgetary constraints and long-term operational goals.

Future Trends in Transformer Insulation Parts Processing Technology

The transformer insulation parts processing industry is evolving rapidly, driven by advancements in automation and smart manufacturing technologies. One emerging trend is the integration of IoT (Internet of Things) capabilities into processing equipment, enabling real-time monitoring and predictive maintenance. These smart machines can alert operators to potential issues before they escalate, reducing unplanned downtime. Another trend is the adoption of AI-driven quality control systems, which use machine learning algorithms to detect defects in electrical cardboard and laminated wood with unparalleled accuracy.

Sustainability is also becoming a key focus, with manufacturers developing eco-friendly processing techniques that minimize waste and energy consumption. For example, some brands are introducing water-based cutting fluids and recyclable insulation materials to reduce environmental impact. As the industry moves towards greener solutions, businesses sourcing transformer insulation parts processing equipment should prioritize brands that align with these sustainability goals. Staying ahead of these trends ensures that your investment remains future-proof and competitive in the evolving market landscape.

Conclusion and Next Steps

Choosing the right transformer insulation parts processing equipment is a critical decision that impacts the quality, efficiency, and cost-effectiveness of your transformer manufacturing operations. By evaluating key factors such as precision, durability, energy efficiency, and compliance with industry standards, businesses can identify the best equipment for their specific needs. Leading brands like Gaomi Hongxiang Electromechanical Technology Co., Ltd. offer reliable solutions backed by extensive industry experience and global support networks.

To ensure you make an informed choice, consider conducting a thorough cost-benefit analysis and staying updated on emerging trends in the industry. For personalized recommendations and expert guidance, contact our team today to explore the best transformer insulation parts processing equipment for your requirements. Let us help you optimize your production processes and achieve superior results in transformer manufacturing.

NAVIGATION

MESSAGE

Request A Quote?