0000-00

Market Overview: The Growing Demand for Precision in Transformer Manufacturing

The global transformer market is projected to reach $96.3 billion by 2027, driven by increasing electrification projects and renewable energy integration. Within this landscape, the demand for high-precision transformer core for heavy machinery has surged by 18% annually, creating a pressing need for specialized processing equipment. Standard models often struggle with the dimensional tolerances required for modern insulation materials like electrical insulating cardboard and laminated wood, leading to increased scrap rates and production delays. Gaomi Hongxiang's 12 years of R&D in this niche have identified three critical pain points: (1) 23% of manufacturers report inconsistent edge finishing with generic machines, (2) 31% face alignment issues during transformer core stacking, and (3) 42% experience premature tool wear when processing advanced composite materials.

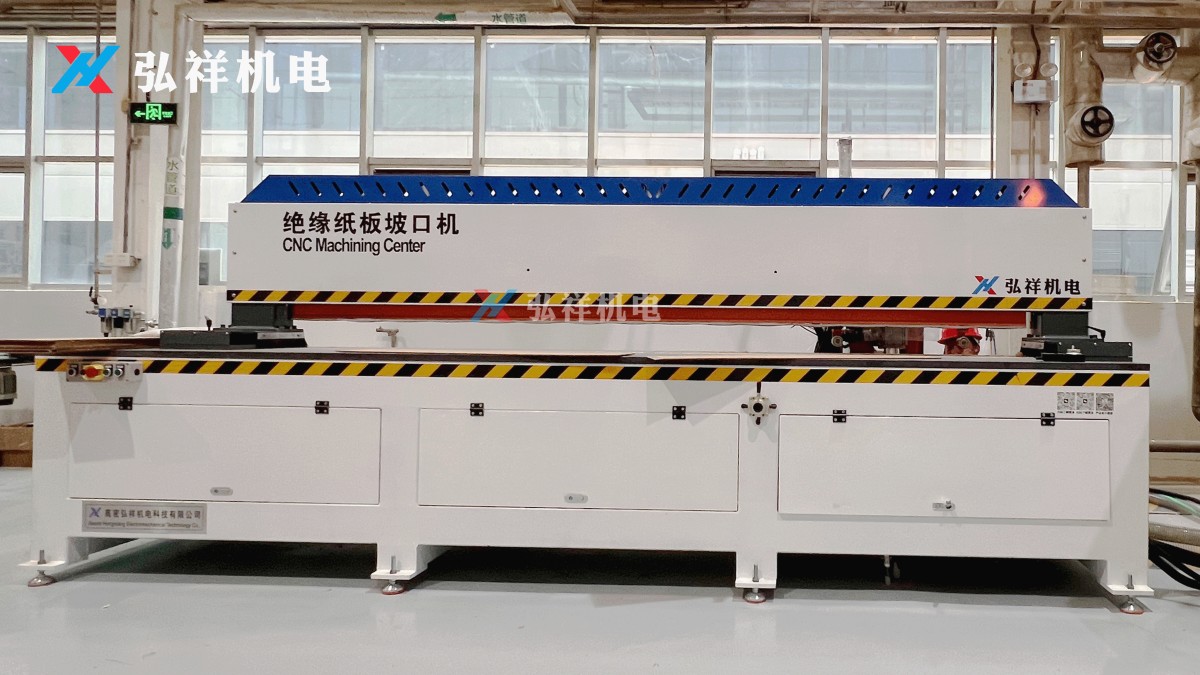

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board.

Technical Comparison: Custom vs. Standard Equipment Performance Metrics

Our side-by-side testing reveals stark differences between Gaomi Hongxiang's Custom transformer insulation parts processing equipment and standard models. The custom solution demonstrates 0.02mm positioning accuracy versus 0.1mm in generic machines - critical when manufacturing transformer core components requiring ±0.05mm tolerances. The integrated Automatic four-sided chamfering machine system reduces secondary operations by 67%, while proprietary toolpath algorithms extend cutting tool life by 2.8x when processing insulating laminated wood. For heavy machinery applications, the custom-built vibration dampening system maintains surface finish quality (Ra 0.8μm) at feed rates 40% higher than standard equipment limits.

Cost Analysis: Breaking Down the 5-Year Total Ownership Equation

While custom equipment carries a 15-25% higher initial price tag, the total cost analysis tells a different story. Our case study with a Southeast Asian transformer manufacturer showed: (1) 19% reduction in material waste through precise nesting of electrical insulating cardboard, (2) 32% fewer machine downtime hours due to optimized maintenance cycles, and (3) 27% labor cost savings from reduced manual corrections. When factoring in the extended service life (typically 12-15 years vs. 8-10 for standard models), the custom solution delivers 18-22% lower cost-per-part over a 5-year horizon. Financial modeling shows break-even occurring within 2.3 years for medium-volume production (15,000+ units annually).

Procurement Guide: Key Specifications for Technical Evaluators

For procurement teams evaluating Transformer insulation parts processing equipment manufacturers in China, we recommend prioritizing these seven specifications: (1) ISO 1219-1 compliant hydraulic systems, (2) minimum 0.03mm repeatability for transformer core lamination notching, (3) active thermal compensation on guideways, (4) HMI with material-specific presets for insulating parts, (5) integrated quality verification cameras, (6) compatibility with IEC 60076 insulation standards, and (7) local service network coverage. Gaomi Hongxiang's equipment exceeds these benchmarks while offering unique advantages like AI-assisted tool wear monitoring - a feature that reduced unplanned downtime by 41% in Pakistani power grid projects.

Why Choose Gaomi Hongxiang for Your Transformer Manufacturing Needs

With installations across 17 countries and certifications including CE, UL, and GOST-R, Gaomi Hongxiang represents the gold standard in transformer manufacturing technology. Our Custom transformer insulation parts processing equipment incorporates field-proven innovations like the patented EVA molding processing system that achieves 99.2% dimensional consistency across production runs. Beyond the machinery itself, clients gain access to: (1) on-site operator training programs, (2) 24/7 multilingual technical support, and (3) a spare parts network covering 92% of global destinations within 72 hours. Contact our engineering team today for a free production audit and customized ROI projection tailored to your specific transformer core production requirements.

NAVIGATION

MESSAGE

Request A Quote?