0000-00

Understanding the Impact of Transformer Insulation Upgrades

Upgrading your transformer insulation system is a critical decision that impacts performance, safety, and operational costs. As a leading Transformer insulation parts processing equipment manufacturer in China, we analyze the cost-benefit ratio of modernizing electrical cardboard, transformer cores, and insulation components. Discover how optimized Transformer insulation components can enhance efficiency while reducing long-term maintenance expenses for your power equipment.

Market Overview: The Growing Demand for Advanced Insulation Solutions

The global transformer market is witnessing a surge in demand for high-performance insulation systems. With increasing energy efficiency regulations and the need for reliable power distribution, industries are prioritizing upgrades to their transformer cores and insulation components. According to recent studies, transformers with modern insulation systems can achieve up to 30% longer lifespan and 15% better energy efficiency. This makes the investment in quality electrical cardboard and insulation parts a strategic decision for any organization.

Technical Performance: Key Parameters of Modern Insulation Systems

When evaluating Transformer insulation components, several technical parameters should be considered. These include dielectric strength (typically ranging from 10kV/mm to 30kV/mm for high-quality materials), thermal class rating (with Class F and H being most common for industrial applications), and mechanical durability. Our manufacturing processes ensure that all electrical cardboard and insulation parts meet or exceed international standards such as IEC 60076 and IEEE C57.12.00.

Cost & Alternatives: Analyzing the True Value Proposition

The initial cost of upgrading Transformer insulation parts might seem significant, but the long-term savings are substantial. Consider these factors:

- Reduced energy losses (up to 2% improvement in efficiency)

- Extended maintenance intervals (potentially doubling service cycles)

- Lower risk of catastrophic failure (saving thousands in unplanned downtime)

- Improved safety compliance (reducing liability risks)

Case Studies: Real-World Benefits of Insulation Upgrades

A recent project with a power distribution company in Southeast Asia demonstrated the tangible benefits of upgrading their transformer core insulation. After implementing our advanced electrical cardboard solution, they achieved:

FAQ & Misconceptions About Transformer Insulation

Q: Can't we just repair existing insulation instead of replacing it?

A: While patch repairs might seem cost-effective, they often lead to inconsistent performance and potential weak points in the insulation system. Complete upgrades using quality Transformer insulation components provide uniform protection and predictable performance.

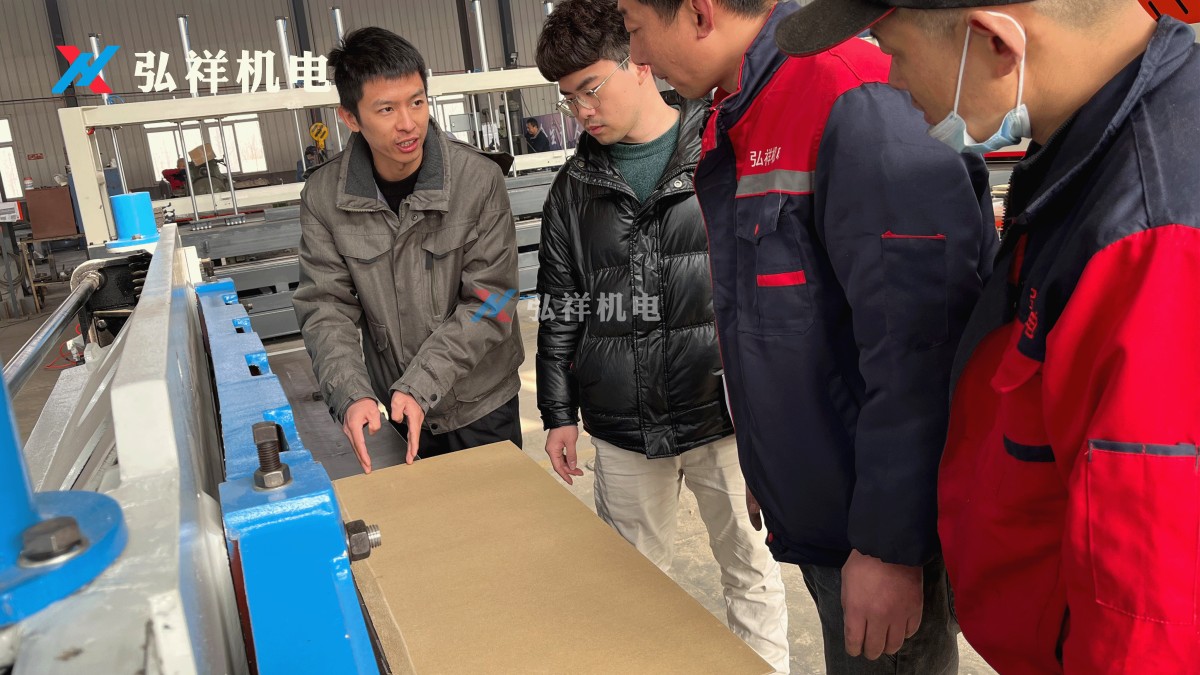

Why Choose Gaomi Hongxiang for Your Insulation Needs?

As a premier Transformer insulation parts processing equipment manufacturer in China, we offer:

- Custom-engineered solutions for specific voltage and environmental requirements

- ISO-certified manufacturing processes with strict quality control

- Global support network with local service centers

- Comprehensive technical documentation and installation guidance

- Competitive pricing with direct manufacturer benefits

Next Steps: Contact Our Technical Team

Ready to evaluate your transformer insulation system? Our experts can provide a customized cost-benefit analysis for your specific application. Contact us today to discuss how our electrical cardboard and Transformer insulation components can optimize your power equipment performance while reducing total cost of ownership.

NAVIGATION

MESSAGE

Request A Quote?