0000-00

Technical Specifications: The Foundation of Quality

When evaluating transformer core suppliers, technical specifications are paramount. Key parameters include core loss, flux density, and temperature rise. Core loss, measured in watts per kilogram (W/kg), directly impacts energy efficiency. Lower core loss values indicate higher quality materials and manufacturing processes. Flux density, typically ranging from 1.5 to 1.8 Tesla, determines the transformer's power handling capacity. Temperature rise, usually limited to 65°C above ambient, affects operational lifespan. Suppliers should provide detailed test reports verifying these specifications, preferably conducted in accordance with IEC 60404-8 standards for magnetic materials.

Manufacturing Capabilities and Equipment

The production of transformer cores requires specialized equipment and precise manufacturing processes. Look for suppliers with advanced cutting and stacking systems that ensure dimensional accuracy within ±0.1mm. Modern facilities should feature laser cutting technology for precision and Automatic four-sided chamfering machine for edge finishing. Production capacity is another critical factor - established manufacturers should demonstrate ability to handle both small prototype batches (as low as 5 units) and large-scale production runs (10,000+ units annually). Ask about their quality control procedures, including 100% dimensional inspection and sample destructive testing protocols.

Material Sourcing and Traceability

High-quality transformer cores begin with premium materials. Leading suppliers source grain-oriented electrical steel (GOES) from reputable mills like Nippon Steel, POSCO, or ThyssenKrupp. Material certifications should include mill test certificates with complete chemical composition and mechanical property data. For industries requiring full traceability, such as nuclear or military applications, ensure the supplier maintains detailed material lot tracking from raw material to finished product. Some manufacturers now offer eco-friendly options using recycled content without compromising performance - an important consideration for sustainability-focused organizations.

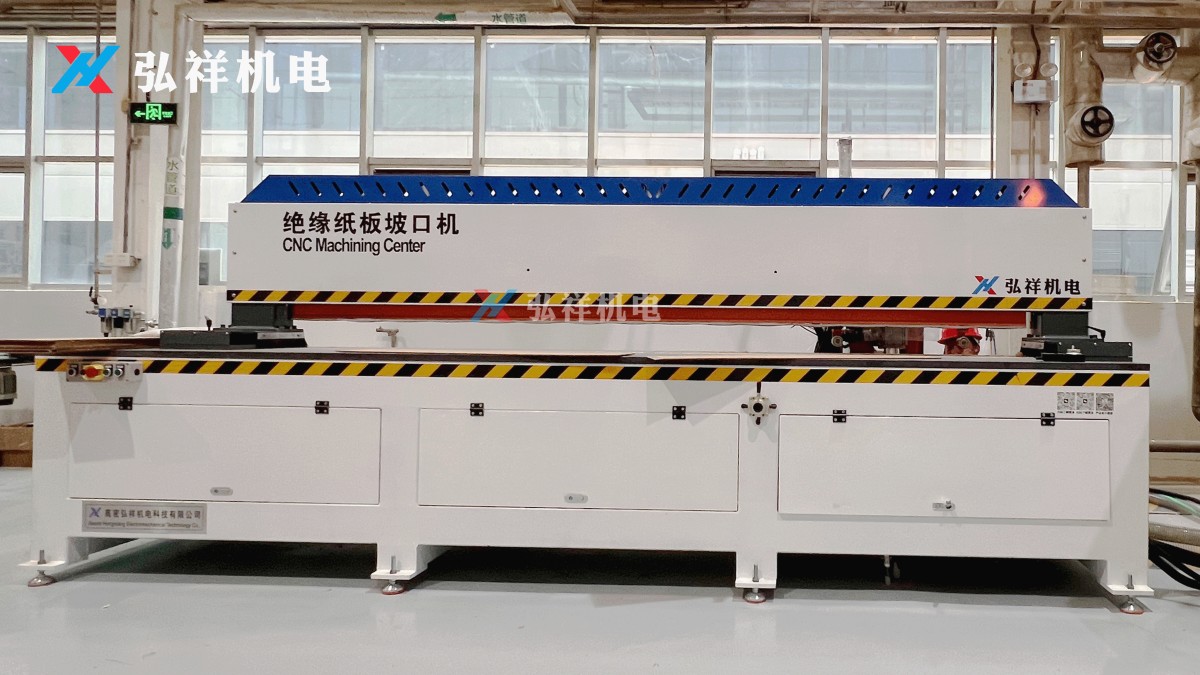

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board.

Customization and Engineering Support

Standard transformer cores may not meet specialized requirements for heavy machinery or unique applications. Evaluate suppliers based on their engineering support capabilities, including:

- CAD modeling and simulation services for custom designs

- Prototyping turnaround time (ideally under 4 weeks)

- Experience with non-standard core shapes (C-cores, E-cores, etc.)

- Ability to integrate special features like cooling ducts or mounting points

Certifications and Compliance

Industry certifications demonstrate a supplier's commitment to quality and safety. Essential certifications for transformer core suppliers include:

Additional certifications like RoHS and REACH compliance may be necessary for European markets. Suppliers should provide current certificates and be willing to undergo customer audits.Why Choose Gaomi Hongxiang Electromechanical Technology

With extensive experience in power transformer manufacturing and insulation parts processing, Gaomi Hongxiang Electromechanical Technology Co., Ltd. stands out as a reliable partner for transformer core solutions. Our vertically integrated production facility combines R&D, precision manufacturing, and quality control under one roof. We serve global clients across multiple industries, from heavy machinery manufacturers to AI equipment developers. Our commitment to continuous improvement and customer support has established our reputation in both domestic Chinese markets and international exports to over 15 countries.

Contact Our Transformer Core Experts

Evaluating transformer core suppliers requires careful consideration of multiple technical and commercial factors. For a detailed consultation about your specific requirements, contact our engineering team today. We'll provide customized recommendations, technical data sheets, and competitive quotations to help you make an informed decision for your power distribution or heavy machinery applications.

NAVIGATION

MESSAGE

Request A Quote?