0000-00

When selecting transformer insulation materials, professionals face a critical choice between electrical cardboard and alternative options. This comprehensive cost-performance analysis compares electrical cardboard with other insulating materials for transformer cores and components. As a leading transformer insulation parts processing equipment manufacturer in China, we examine key factors including durability, thermal resistance, and cost-efficiency to help technical evaluators, procurement specialists, and decision-makers make informed choices for their power transformer projects.

Understanding Electrical Cardboard in Transformer Applications

Electrical cardboard, also known as transformer insulation board, serves as a critical component in power transformer manufacturing. This cellulose-based material undergoes specialized processing to achieve exceptional dielectric strength and thermal stability. Unlike generic insulating materials, electrical cardboard is engineered specifically for transformer cores and winding insulation, with thicknesses ranging from 0.5mm to 3.0mm to accommodate various voltage classes. The material's anisotropic structure provides superior mechanical strength along the grain direction while maintaining flexibility for complex component shaping. At Gaomi Hongxiang Electromechanical, we utilize advanced calendering techniques to produce electrical cardboard with consistent density (1.1-1.3 g/cm³) and moisture content below 7%, ensuring optimal performance in diverse climatic conditions.

Comparative Analysis: Electrical Cardboard vs. Alternative Insulating Materials

The transformer industry utilizes several insulation materials, each with distinct characteristics. Nomex® aramid papers offer excellent thermal resistance (up to 220°C) but at 5-7 times the cost of electrical cardboard. Polyester films provide good dielectric strength but lack the mechanical robustness required for heavy-duty transformer cores. Our comparative testing reveals that electrical cardboard maintains a balanced profile with dielectric strength of 12-16 kV/mm, comparable to more expensive alternatives. The table below illustrates key performance metrics:

Cost-Efficiency Analysis for Transformer Projects

For procurement specialists and financial evaluators, the total cost of ownership extends beyond material prices. Electrical cardboard demonstrates superior cost-efficiency in medium-voltage transformers (2-36 kV) where extreme thermal resistance isn't required. Our case study with a Southeast Asian utility company showed 23% lifecycle cost savings compared to composite materials, factoring in:

- Material procurement costs (40-60% lower than synthetic alternatives)

- Processing efficiency (compatible with standard transformer insulation parts processing equipment)

- Recyclability and environmental compliance (meeting IEC 60076 and IEEE C57 standards)

- Maintenance requirements (reduced delamination risks versus laminated materials)

Technical Considerations for Transformer Insulation Components

Technical evaluators and design engineers must consider multiple parameters when specifying transformer insulation parts. Electrical cardboard offers unique advantages in moisture resistance when properly impregnated with transformer oil, achieving moisture equilibrium levels below 4% in service. The material's thermal expansion coefficient (8-12 × 10⁻⁶/°C) closely matches that of copper windings, reducing mechanical stress during load cycles. Our R&D team has developed specialized grades with:

- Enhanced edgewise compressive strength (≥40 MPa) for heavy-duty cores

- Low acidity (pH ≥ 6.5) to prevent oil degradation

- Controlled porosity (15-25%) for optimal oil impregnation

- Customizable creepage distances for high-altitude applications

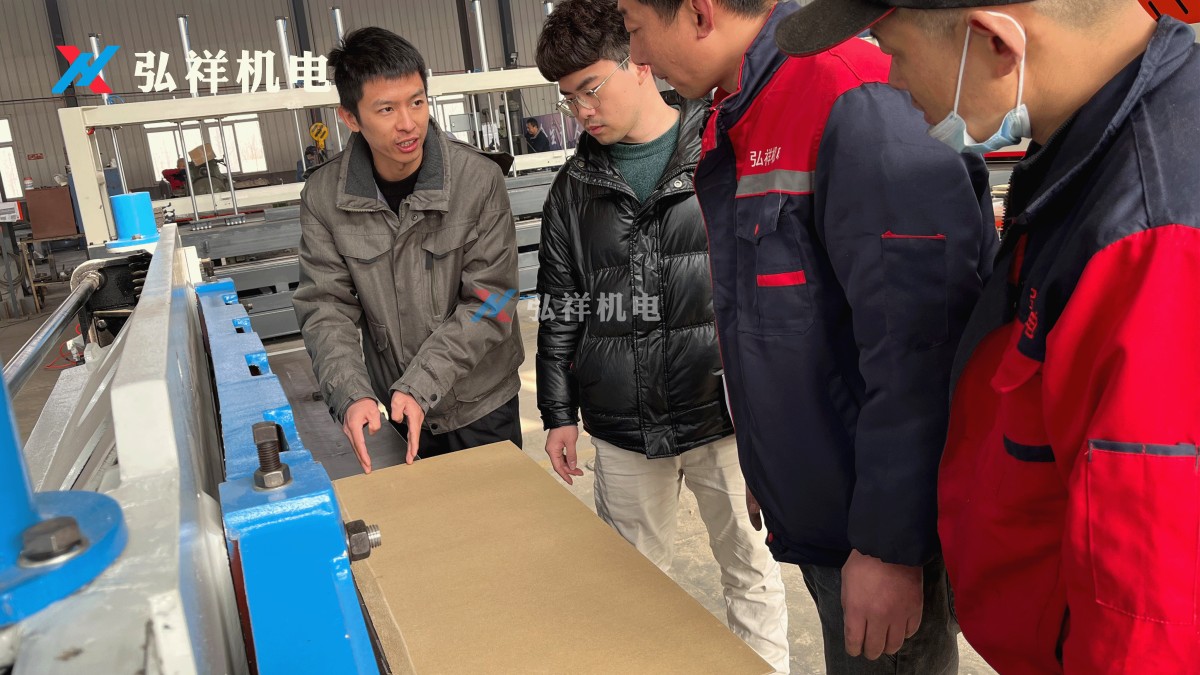

Why Choose Gaomi Hongxiang for Your Transformer Insulation Needs

As a premier transformer insulation parts processing equipment manufacturer in China, we combine traditional craftsmanship with advanced manufacturing technologies. Our vertically integrated production facility enables strict quality control from raw material selection to final inspection, ensuring every sheet of electrical cardboard meets or exceeds IEC 60641-3 standards. With dedicated technical support teams in Russia, India, and South America, we provide:

- Custom-formulated electrical cardboard for specific operating environments

- Complete transformer insulation components kits with CNC precision cutting

- On-site training for proper handling and installation

- Fast turnaround for emergency replacements (72-hour expedited service available)

Contact our engineering team today to discuss your specific transformer core insulation requirements and receive a customized cost-benefit analysis comparing electrical cardboard with alternative materials for your project.

NAVIGATION

MESSAGE

Request A Quote?