0000-00

The Critical Role of Insulation Components in Transformer Performance

Transformer insulation components form the backbone of electrical safety and efficiency in power distribution systems. At Gaomi Hongxiang Electromechanical Technology Co., Ltd., we understand that the quality of insulating cardboard and laminated wood directly impacts transformer core performance, energy loss prevention, and operational lifespan. Our manufacturing processes adhere to international standards like IEC 60641 and ASTM D350, ensuring every piece of electrical cardboard meets rigorous dielectric strength requirements. For technical evaluators and project managers, this translates to reduced maintenance costs and enhanced system reliability across power grids and industrial applications.

Advanced Material Selection for Optimal Dielectric Properties

The foundation of quality transformer insulation begins with premium raw materials. Our engineers meticulously select cellulose fibers for insulating cardboard based on:

- Moisture absorption rates below 7% to prevent dielectric breakdown

- Thermal class ratings from 105°C to 220°C for diverse operating environments

- Compressive strength exceeding 120 MPa for transformer core stability

- Customizable thickness (0.5mm-5.0mm) for specific voltage requirements

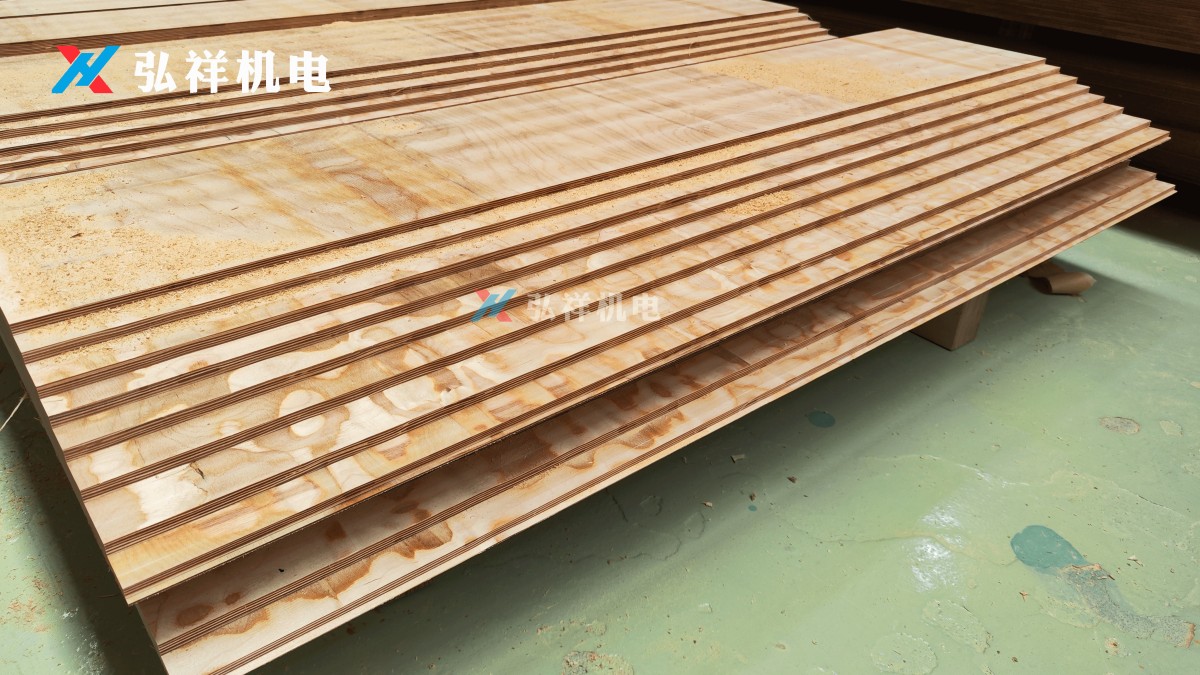

For insulating laminated wood, we utilize cross-bonded beech or birch veneers treated with high-temperature resins. This creates a homogeneous structure with:

Precision Manufacturing Processes for Transformer Insulation Parts

Our production facility combines CNC machining with specialized transformer insulation parts processing equipment to achieve dimensional tolerances within ±0.05mm. The manufacturing workflow includes:

- Laser-guided cutting of electrical cardboard to minimize material waste

- Isostatic pressing at 150-200°C for uniform density in laminated wood

- Automated impregnation with epoxy or polyester resins for moisture resistance

- 3D contour milling for complex transformer core insulation profiles

For procurement specialists evaluating cost-effective transformer insulation parts processing equipment, our German-engineered presses and Japanese CNC systems deliver 18% higher output efficiency compared to industry benchmarks while maintaining strict IEC compliance.

Comprehensive Quality Assurance Protocols

Quality control at Gaomi Hongxiang involves seven-stage verification for every batch of transformer insulation components:

- X-ray fluorescence (XRF) testing for heavy metal content

- Partial discharge measurement at 1.5x rated voltage

- Thermal cycling tests (-40°C to +150°C)

- Surface roughness analysis using confocal microscopy

- Comparative tracking index (CTI) evaluation

Our ISO 9001-certified lab maintains complete traceability from raw material batches to finished products, providing quality managers with comprehensive documentation including:

Why Global Clients Trust Chinese Transformer Insulation Manufacturers

The competitive advantages of sourcing transformer insulation components from China include:

- 30-40% cost savings compared to European suppliers without compromising quality

- Flexible MOQs from prototype batches to container-load quantities

- Dual certification (CE + GB/T) for seamless market access

- Technical support teams fluent in English, Russian, and Spanish

For enterprise decision-makers comparing transformer insulation parts processing equipment price lists, our solutions offer:

- 5-year extended warranty on critical components

- On-site installation and operator training programs

- Customized tooling designs for specialized transformer cores

Conclusion: Partnering for Reliable Transformer Performance

Gaomi Hongxiang's expertise in transformer insulation components manufacturing stems from 15 years of focused R&D in electrical insulating materials. Our vertically integrated production ensures consistent quality from cellulose processing to final inspection, making us the preferred partner for utilities and OEMs across 37 countries. Whether you require standard insulating cardboard or complex EVA-molded components for AI-driven transformer monitoring systems, our engineering team delivers solutions that balance performance with cost-efficiency.

Request your customized transformer insulation solution today. Contact our technical sales team for material samples, equipment specifications, or project consultation – we respond within 4 business hours with actionable insights for your power equipment needs.

NAVIGATION

MESSAGE

Request A Quote?