0000-00

Evaluating transformer insulation parts processing equipment requires careful analysis of performance metrics, durability, and precision. As a leading manufacturer of electrical cardboard and laminated wood components, Gaomi Hongxiang understands the critical factors that impact transformer insulation quality. This guide helps technical evaluators, procurement specialists, and project managers compare equipment capabilities across brands while considering operational efficiency and long-term reliability for industrial applications.

Key Performance Metrics for Transformer Insulation Parts Processing Equipment

When evaluating transformer insulation parts processing equipment, several critical performance metrics must be considered to ensure optimal operation and long-term reliability. These metrics directly impact the quality of electrical cardboard, laminated wood components, and other insulating materials used in power transformers.

Precision and Tolerance Levels

High-quality transformer insulation parts processing equipment must maintain exceptional precision, typically within ±0.05mm tolerance for critical dimensions. This level of accuracy is essential when working with electrical cardboard and insulating laminated wood, where even minor deviations can affect transformer performance. Equipment should feature advanced CNC controls and laser measurement systems to verify dimensional accuracy throughout the production process.

Production Speed and Cycle Times

Industrial-grade transformer insulation processing equipment should balance speed with precision. Modern machines typically achieve cycle times of 15-30 seconds for standard electrical cardboard components, with throughput rates varying based on complexity. When comparing different brands, consider the equipment's ability to maintain consistent speed without compromising the quality of insulating parts.

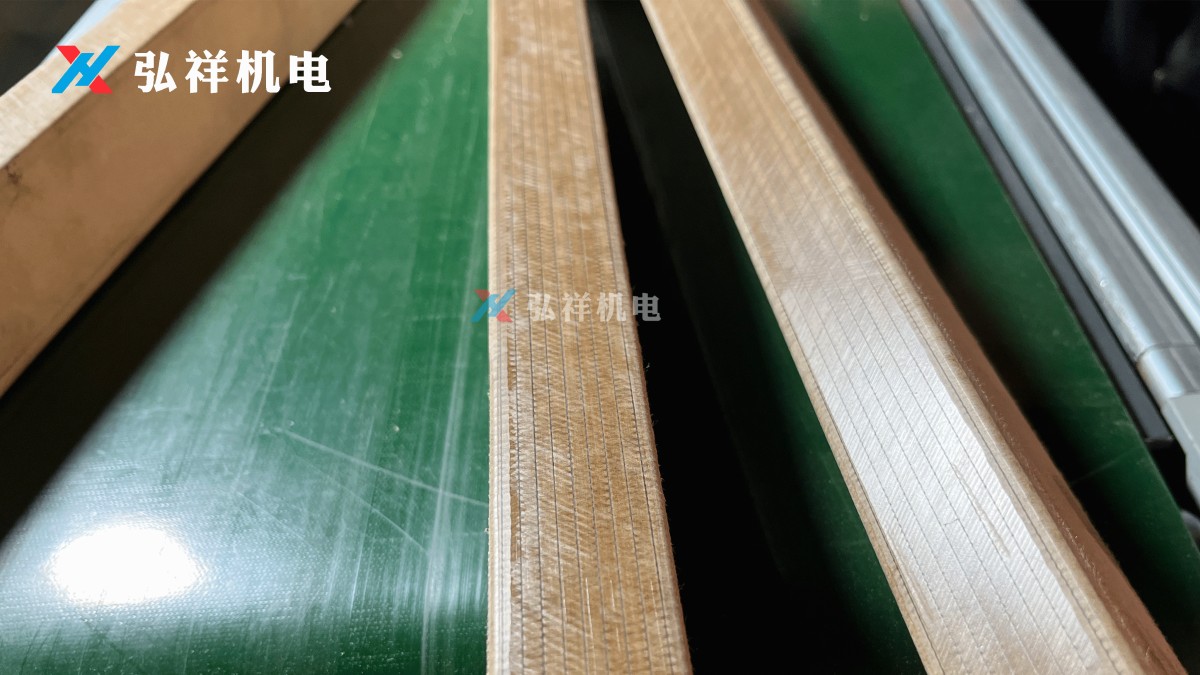

Material Compatibility and Versatility

Top-tier processing equipment should accommodate various insulating materials, including Nomex, pressboard, and epoxy composites. The ability to switch between materials without extensive recalibration significantly enhances operational efficiency. Look for machines with quick-change tooling systems and automated adjustment capabilities when sourcing transformer insulation parts processing equipment.

Durability and Maintenance Considerations

The longevity and maintenance requirements of transformer insulation processing equipment significantly impact total cost of ownership and production uptime. Industrial users should evaluate several durability factors before making procurement decisions.

Construction Quality and Component Lifespan

Premium equipment features heavy-duty cast iron or steel frames with vibration-dampening properties, essential for maintaining precision during extended operation. Critical components like spindles and guideways should have minimum service lives of 50,000 operating hours. When comparing different brands of insulating cardboard processing equipment, request detailed documentation about component specifications and expected lifespans.

Maintenance Accessibility and Service Requirements

Well-designed transformer insulation parts processing equipment incorporates modular construction for easy maintenance. Features to prioritize include front-access service panels, centralized lubrication points, and tool-less component replacement where possible. Evaluate the manufacturer's recommended maintenance schedule - top performers typically require only quarterly servicing under normal operating conditions.

Corrosion Resistance and Environmental Protection

Given the cellulose dust and potential moisture exposure in transformer component production, equipment should feature IP54-rated protection at minimum. Critical surfaces should have special coatings or treatments to resist corrosion from insulating material byproducts. This is particularly important for equipment processing electrical cardboard and laminated wood in humid climates.

Comparative Analysis of Equipment Brands

When evaluating different brands of transformer insulation parts processing equipment, technical buyers should develop a systematic comparison framework. This approach ensures objective assessment across multiple parameters relevant to industrial applications.

Performance Benchmarking Methodology

Establish standardized test protocols to compare equipment from various manufacturers. Key tests should include:

- Dimensional accuracy verification using certified test pieces

- Continuous operation stress tests (72+ hours)

- Material changeover efficiency measurements

- Energy consumption per unit of output

- Noise and vibration levels at maximum operating speed

Total Cost of Ownership Analysis

Beyond initial purchase price, evaluate all cost factors over a 7-10 year equipment lifespan:

Safety and Compliance Standards

Transformer insulation parts processing equipment must comply with stringent international safety standards while incorporating features to protect operators and maintain product quality.

Essential Safety Features

Modern equipment should include:

- Light curtains or laser scanners for operator protection

- Automatic dust extraction systems meeting OSHA standards

- Emergency stop circuits with redundant monitoring

- Thermal monitoring for motors and drives

- Ground-fault protection for electrical systems

Industry Compliance Requirements

Verify that equipment meets or exceeds these standards:

- IEC 60204-1 for electrical safety

- ISO 13849 for safety-related control systems

- CE marking for European market compliance

- UL certification for North American markets

- Industry-specific standards for transformer component manufacturing

Conclusion and Next Steps

Evaluating transformer insulation parts processing equipment requires comprehensive analysis of technical specifications, operational efficiency, safety features, and long-term reliability. Gaomi Hongxiang's expertise in electrical cardboard and laminated wood component manufacturing provides unique insights into equipment selection criteria that truly impact transformer performance.

For technical evaluators and procurement specialists seeking high-performance solutions, we recommend:

- Requesting detailed equipment specifications from multiple suppliers

- Conducting on-site demonstrations with your specific materials

- Reviewing case studies from similar transformer manufacturing operations

- Evaluating after-sales support and service network coverage

Contact Gaomi Hongxiang's technical team today to discuss your transformer insulation parts processing requirements and receive customized equipment recommendations based on your specific production needs and quality standards.

NAVIGATION

MESSAGE

Request A Quote?