0000-00

Discover how transformer insulation parts processing equipment can revolutionize your production efficiency. This guide explores key considerations when sourcing industrial-grade electrical cardboard and laminated wood processing solutions. Learn to evaluate different brands of insulating materials and optimize your transformer manufacturing workflow. Whether you're a procurement specialist, plant manager, or technical evaluator, these insights will help you make informed decisions about equipment selection and operational improvements.

The Critical Role of Transformer Insulation Parts Processing Equipment

Transformer insulation parts form the backbone of electrical safety and performance in power distribution systems. The specialized equipment used to process electrical cardboard, laminated wood, and other insulating materials directly impacts product quality, production throughput, and operational costs. Industrial-grade transformer insulation processing machines must meet exacting standards for precision cutting, dimensional accuracy, and material handling. Modern solutions now incorporate advanced features like CNC controls, automated feeding systems, and real-time quality monitoring to address the growing demand for high-voltage insulation components in energy infrastructure projects worldwide.

Key Performance Indicators for Industrial Processing Equipment

When evaluating transformer insulation parts processing equipment, technical buyers should prioritize these critical specifications:

- Cutting Precision: Tolerance levels below ±0.1mm for high-voltage applications

- Material Compatibility: Ability to process diverse insulation materials (NOMEX, pressboard, epoxy composites)

- Production Capacity: Throughput rates exceeding 500 components/hour for large-scale operations

- Energy Efficiency: Power consumption metrics compared to industry benchmarks

- Safety Features: Integrated dust extraction, emergency stop systems, and operator protection mechanisms

Comparative Analysis of Insulating Material Processing Solutions

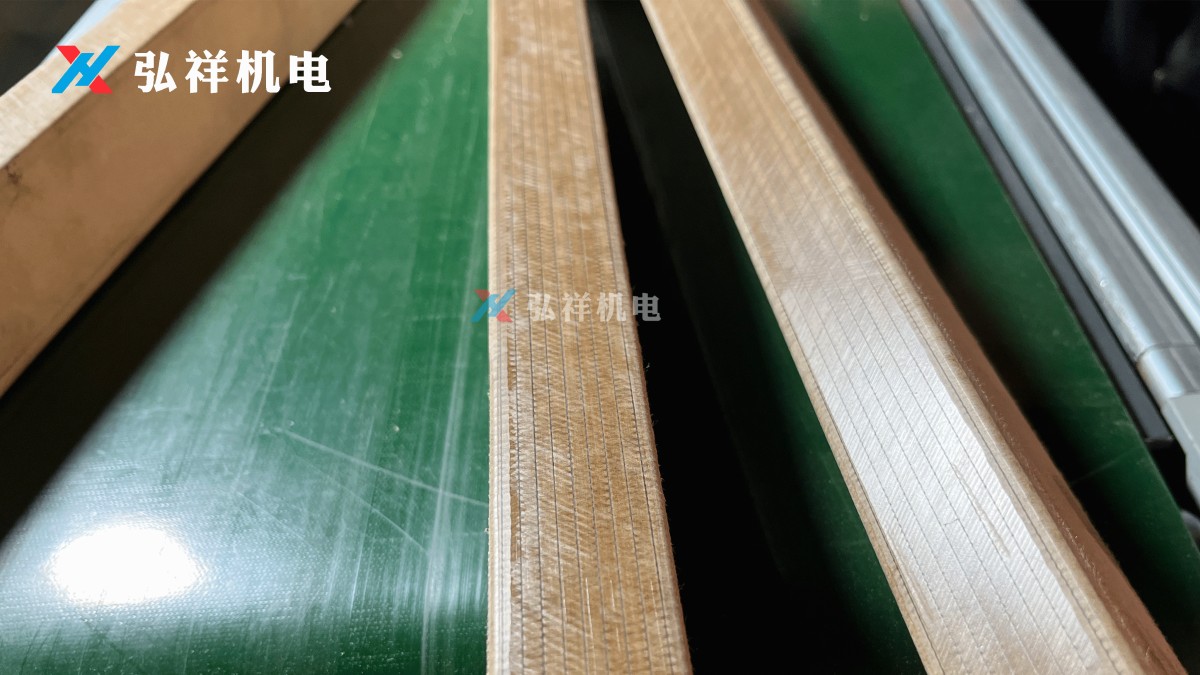

The market offers various approaches to transformer insulation manufacturing, each with distinct advantages for specific applications. Laminated wood processing equipment typically requires heavy-duty pressing capabilities and precise moisture control systems, while electrical cardboard processing machines focus on clean cutting edges and minimal material waste. Advanced EVA molding systems have emerged as particularly valuable for creating complex geometric insulation components with consistent dielectric properties. When comparing brands, consider not only initial capital expenditure but also long-term factors like maintenance requirements, spare parts availability, and compatibility with your existing production workflow.

Technical Evaluation Framework for Procurement Teams

Procurement specialists should implement a structured assessment methodology when sourcing transformer insulation processing equipment:

Operational Optimization Strategies for Production Managers

Maximizing the ROI of transformer insulation processing equipment requires strategic operational practices. Implement lean manufacturing principles to reduce material waste during electrical cardboard conversion processes. Standardized work instructions for machine operators can significantly improve consistency in laminated wood component production. Many facilities achieve 15-20% productivity gains by integrating their insulation processing equipment with Industry 4.0 systems for real-time performance monitoring and predictive maintenance. Temperature and humidity control in the production environment also proves critical for maintaining the dielectric properties of processed insulation materials.

Safety and Compliance Considerations

Transformer insulation manufacturing involves compliance with multiple international standards, including IEC 60641 for pressboard and IEC 60893 for industrial laminated sheets. Processing equipment must facilitate compliance with these specifications through features like:

- Controlled pressure application during lamination processes

- Precision thickness monitoring systems

- Documentation of processing parameters for quality audits

- Built-in testing protocols for dielectric strength verification

Global Sourcing Insights for Transformer Insulation Equipment

The international market for transformer insulation processing equipment presents both opportunities and challenges. While European manufacturers traditionally dominated the high-end segment, Asian suppliers like Gaomi Hongxiang Electromechanical Technology have gained significant market share by combining competitive pricing with technical sophistication. When sourcing globally, consider total cost of ownership factors including shipping logistics, import duties, and after-sales support availability. Many procurement teams now adopt a hybrid approach - purchasing core processing equipment from established brands while sourcing auxiliary components from value-driven manufacturers.

Future Trends in Insulation Parts Manufacturing Technology

The transformer insulation processing equipment sector is undergoing rapid technological evolution. Emerging developments include AI-powered quality inspection systems that automatically detect material imperfections, robotic handling solutions for delicate insulation components, and advanced simulation software that optimizes cutting patterns to minimize waste. Sustainable manufacturing practices are also gaining prominence, with equipment manufacturers developing solutions for recycling insulation material byproducts. These innovations promise to redefine efficiency benchmarks in electrical cardboard and laminated wood processing operations.

Conclusion: Strategic Equipment Selection for Competitive Advantage

Optimizing your transformer insulation parts production requires careful evaluation of processing equipment capabilities, operational integration, and long-term maintenance considerations. The right industrial processing solutions can deliver measurable improvements in product quality, production efficiency, and overall equipment effectiveness.

Ready to transform your insulation manufacturing capabilities? Contact our engineering team at Gaomi Hongxiang Electromechanical Technology for a customized equipment assessment and discover how our three major product series can address your specific transformer component production challenges. With extensive experience serving global markets from Southeast Asia to South America, we provide comprehensive solutions from initial consultation through after-sales support.

NAVIGATION

MESSAGE

Request A Quote?