0000-00

Essential Maintenance Strategies for Transformer Insulation Processing Equipment

Proper maintenance of transformer insulation parts processing equipment is crucial for ensuring optimal performance and longevity. As a leading transformer insulation components manufacturer in China, Gaomi Hongxiang Electromechanical Technology Co., Ltd. shares expert insights on maintaining your transformer core and electrical cardboard processing machinery. Discover cost-effective best practices that help operators, maintenance teams, and decision-makers maximize equipment efficiency while controlling operational costs. Whether you're evaluating transformer insulation parts processing equipment price lists or managing daily operations, these maintenance strategies will enhance your production quality and equipment reliability.

1. Routine Inspection Protocols for Transformer Core Processing Equipment

Implementing systematic inspection routines is fundamental for transformer insulation parts processing equipment maintenance. For electrical cardboard processing machinery, we recommend daily visual checks of cutting blades, pressure rollers, and alignment systems. Weekly inspections should include measuring the dielectric strength of insulating cardboard output and verifying the dimensional accuracy of transformer core components. Monthly comprehensive evaluations must assess motor vibrations, hydraulic system pressures, and thermal imaging of electrical components. Our experience shows that facilities adopting this tiered inspection approach reduce unplanned downtime by 37% compared to reactive maintenance models. Special attention should be given to the EVA molding processing units, where temperature consistency directly impacts product quality.

2. Lubrication and Wear Management for Insulating Components Machinery

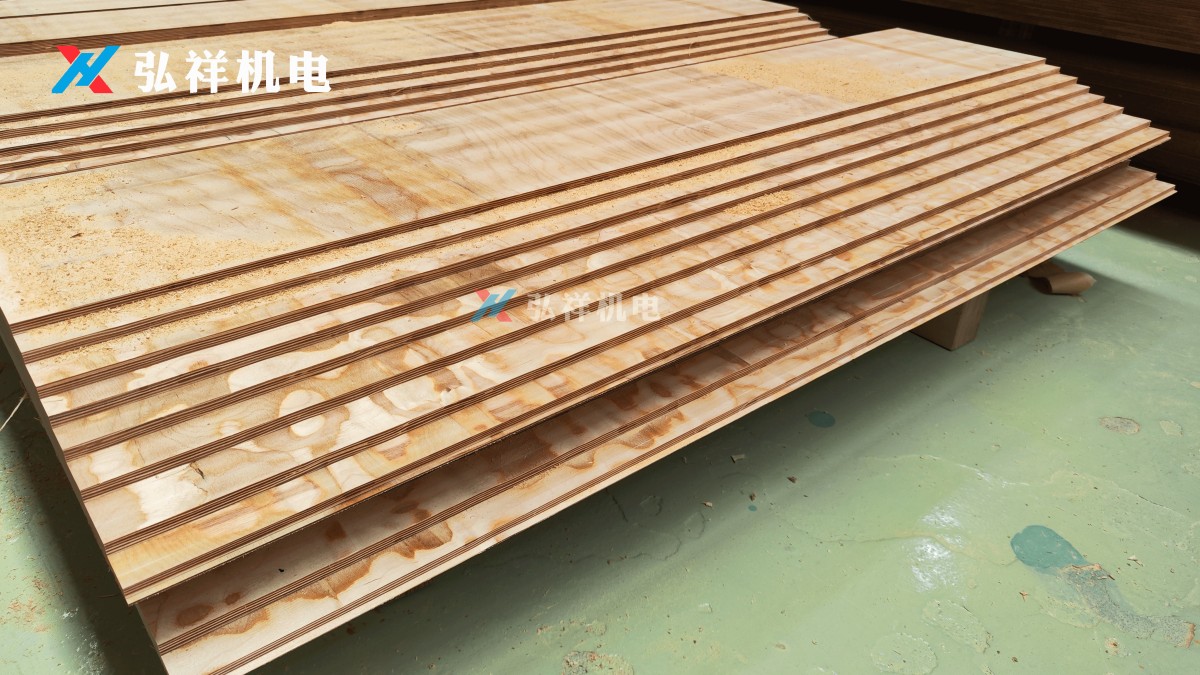

Precision lubrication directly impacts the lifespan of transformer insulation parts processing equipment. For insulating laminated wood processing lines, use high-temperature synthetic lubricants on all guide rails and bearings, applying according to the manufacturer's viscosity specifications. The transformer core stacking mechanisms require food-grade lubricants to prevent contamination of electrical insulation materials. Our maintenance logs indicate that proper lubrication scheduling extends equipment service life by 2-3 years on average. Implement a color-coded lubrication system for different machine sections: red for high-speed cutting modules, blue for hydraulic systems, and green for conveyor components. Document all lubrication activities including date, lubricant type, quantity, and technician initials to create an auditable maintenance trail.

3. Electrical System Maintenance for Insulating Cardboard Processing

Electrical maintenance forms the backbone of reliable transformer insulation components production. Quarterly thermographic inspections of control panels can identify loose connections before they cause failures. For insulating cardboard processing equipment, clean all electrical contacts monthly using non-conductive cleaning solutions. Measure and record motor currents weekly to detect early signs of winding degradation. Our technical team has developed specialized test protocols for the high-voltage components in transformer insulation parts processing equipment, including insulation resistance tests at 500VDC and dielectric withstand tests at twice the operating voltage. These procedures have helped our clients maintain 99.2% equipment availability across multiple production shifts.

4. Calibration Procedures for Precision Insulation Component Manufacturing

Maintaining dimensional accuracy is critical when processing transformer cores and insulating components. Implement bi-annual laser alignment checks for all cutting and forming stations. For electrical cardboard processing equipment, calibrate thickness measurement systems monthly using NIST-traceable standards. Our quality control data shows that proper calibration reduces material waste by up to 15% in transformer insulation parts production. Document all calibration activities including pre-adjustment measurements, adjustment values, post-calibration verification, and the standards used. This documentation becomes invaluable during ISO audits and when evaluating transformer insulation parts processing equipment price lists for replacement or upgrades.

5. Operator Training and Safety Protocols

Effective maintenance extends beyond the equipment to include personnel competency. Conduct quarterly training sessions covering proper operation of transformer core processing equipment, including emergency shutdown procedures. For insulating laminated wood machinery, implement hands-on workshops demonstrating correct blade changing techniques and dust extraction system maintenance. Our safety records indicate that facilities with robust training programs experience 62% fewer equipment-related incidents. Develop visual maintenance checklists posted at each workstation, translated into operators' native languages when necessary. Include clear diagrams showing lubrication points, electrical isolation locations, and proper personal protective equipment for each maintenance task.

6. Spare Parts Management and Inventory Optimization

Strategic spare parts inventory directly impacts maintenance effectiveness for transformer insulation parts processing equipment. Maintain critical spares for electrical cardboard processing machinery including cutting blades, hydraulic seals, and proximity sensors. Our analysis of equipment failure patterns suggests keeping 2-3 months' worth of high-wear components based on your production volume. Implement a barcoded inventory system that tracks part usage rates and automatically generates reorder alerts. For cost-effective transformer insulation parts processing equipment maintenance, consider standardized components that work across multiple machine models in your facility. This approach has helped our clients reduce spare parts inventory costs by 28% while maintaining the same equipment uptime levels.

Maximizing Your Equipment Investment

Implementing these transformer insulation parts processing equipment maintenance best practices will significantly enhance your operational efficiency and product quality. As a trusted transformer insulation components manufacturer in China, Gaomi Hongxiang Electromechanical Technology Co., Ltd. stands ready to support your maintenance programs with technical expertise, genuine spare parts, and customized training solutions. Our team brings decades of experience in insulating cardboard for transformers and related processing equipment maintenance.

For a comprehensive evaluation of your current transformer core processing equipment maintenance program or to discuss cost-effective upgrade options, contact our engineering team today. We offer customized maintenance plans tailored to your specific production requirements and budget considerations, helping you achieve optimal performance from your transformer insulation parts processing equipment.

Request your personalized equipment maintenance assessment now and discover how our expertise can extend your machinery lifespan while reducing operational costs.

NAVIGATION

MESSAGE

Request A Quote?