0000-00

When selecting reliable transformer insulation parts processing equipment, manufacturers and engineers must prioritize precision, durability, and compliance with international standards. As a leading transformer insulation components manufacturer in China, Gaomi Hongxiang specializes in high-performance solutions for electrical cardboard, laminated wood, and core insulation processing. This guide explores critical factors for evaluating transformer insulation parts processing equipment to ensure optimal performance, safety, and cost-efficiency for your power transformer projects.

1. Market Overview: The Growing Demand for Precision Transformer Insulation Processing

The global power transformer market is projected to reach $38.5 billion by 2027, driven by renewable energy integration and grid modernization. This growth directly impacts demand for high-precision transformer insulation parts processing equipment, particularly in regions with expanding energy infrastructure like Southeast Asia and South America where Gaomi Hongxiang has established strong export channels.

Key industry trends influencing equipment selection include:

- Increasing adoption of dry-type transformers requiring specialized insulating cardboard processing

- Stricter IEC 60076 standards for dielectric strength in transformer cores

- Demand for automated solutions that reduce material waste in electrical cardboard cutting

Integration of AI-assisted quality control systems in processing lines

2. Technical Specifications: What Matters in Processing Equipment

When evaluating transformer insulation parts processing equipment, these technical parameters determine long-term performance:

3. Procurement Guide: 5 Critical Selection Factors

For transformer core and insulation component manufacturers, these evaluation criteria prevent costly mistakes:

- Material Compatibility: Equipment must process both traditional insulating laminated wood and modern composite materials

- Production Volume: Match equipment throughput (pieces/hour) to your transformer manufacturing cycle

- Energy Efficiency: Look for ISO 50001 compliant systems to reduce operating costs

- Safety Features: Essential for processing flammable insulating cardboard for transformers

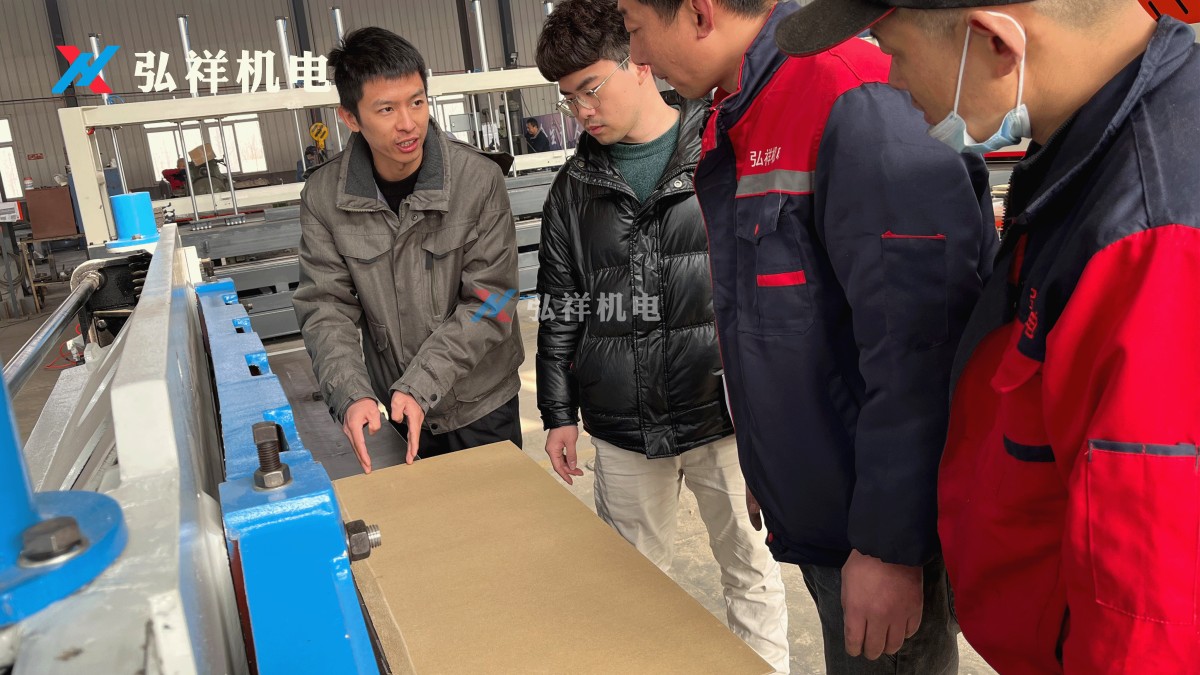

- After-Sales Support: Gaomi Hongxiang provides installation supervision and operator training

4. Why Choose Gaomi Hongxiang?

As a transformer insulation parts processing equipment manufacturer in China with 15+ years of industry experience, we offer:

- Customized solutions for special transformer insulation components

- Complete production lines from raw material processing to final inspection

- 24/7 technical support with multilingual service teams

- CE, UL, and GOST-R certified equipment

Contact our engineering team today to discuss your specific transformer insulation parts processing requirements and receive a customized equipment proposal.

NAVIGATION

MESSAGE

Request A Quote?