0000-00

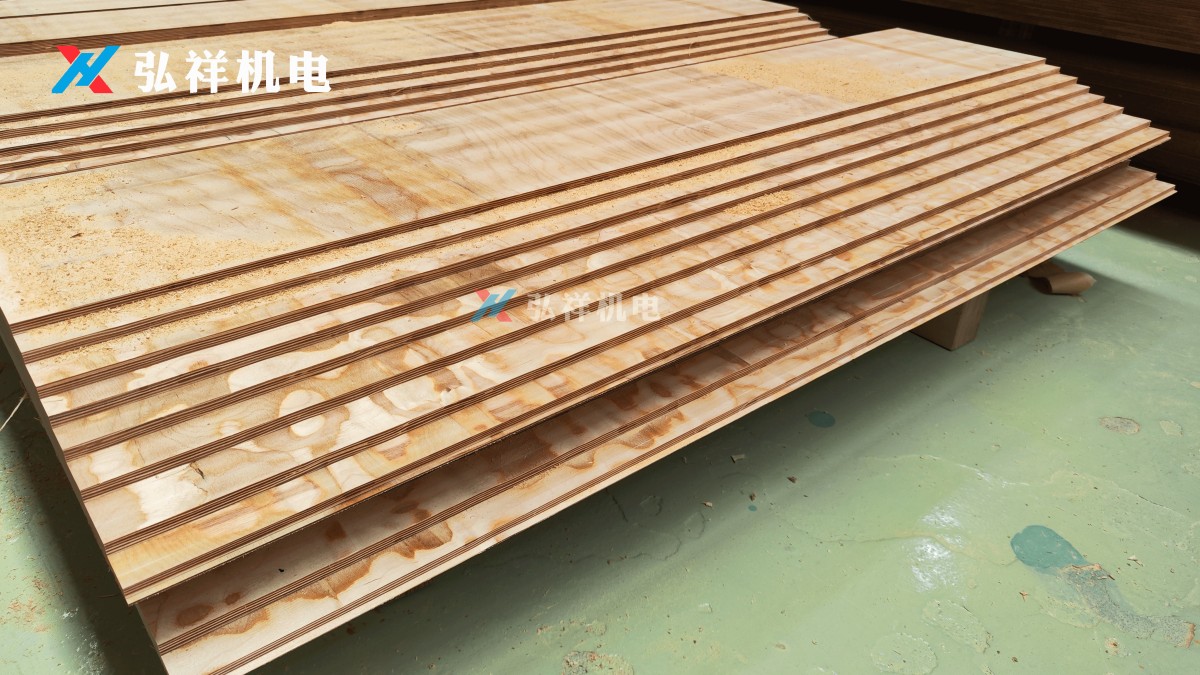

Material Quality: The Foundation of Reliable Transformer Core Insulation

When evaluating insulating cardboard for transformer cores, material composition directly impacts performance longevity. Premium-grade electrical cardboard typically consists of cellulose fibers bonded with synthetic resins, achieving a density range of 1.0-1.2 g/cm³ for optimal structural integrity. Our ISO 9001-certified manufacturing process ensures uniform fiber distribution, critical for preventing hot spots in high-voltage applications (15kV-500kV). Technical evaluators should verify the material's thermal conductivity (0.12-0.15 W/m·K) and moisture absorption rates (<5% at 90% RH), as these parameters significantly influence dielectric strength. For projects involving oil-immersed transformers, we recommend materials with certified compatibility with mineral oils and ester fluids per IEC 60641-2 standards.

Key Material Specifications to Request

- Fiber purity certification (minimum 95% cellulose content)

- Resin impregnation depth reports (should exceed 80% penetration)

- Thermal aging test results (5000+ hours at 105°C)

- Comparative tracking index (CTI) ≥ 250V

- Partial discharge characteristics (<10pC at 1.5Ur)

Dielectric Properties: Ensuring Electrical Safety in Transformer Cores

The dielectric strength of insulating cardboard determines its ability to withstand electrical stress within transformer cores. Our laboratory tests demonstrate that properly processed electrical cardboard maintains breakdown voltages of 40-60 kV/mm under dry conditions and 25-35 kV/mm when oil-impregnated. Project managers should pay particular attention to the material's dielectric loss tangent (tan δ), which should remain below 0.02 at power frequencies (50/60Hz) to minimize energy losses. For applications involving high-frequency transformers (e.g., renewable energy systems), we've developed specialized grades with stable permittivity (εr 3.5-4.2) across 1kHz-1MHz ranges.

Mechanical Durability: Withstanding Transformer Operational Stresses

Transformer core insulating cardboard must endure significant mechanical stresses throughout its service life. Our stress analysis reveals that premium insulation materials maintain compressive strength exceeding 120 MPa after 20,000 thermal cycles (-40°C to +150°C). Procurement specialists should evaluate the material's tensile strength (minimum 80 N/mm²) and elongation at break (>5%) to ensure compatibility with winding pressures. For large power transformers (≥100MVA), we've engineered reinforced laminates with 30% higher flexural modulus than standard grades, significantly reducing the risk of delamination during short-circuit events.

Durability Testing Protocols

- Accelerated aging tests simulating 30+ years of service

- Vibration resistance testing per IEEE C57.12.90

- Oil compatibility immersion studies (1000+ hours)

- Thermal shock cycling (-55°C to +155°C, 100 cycles)

- Radial compression testing under load (up to 50kN)

Cost-Effectiveness: Balancing Performance and Budget

While transformer insulation components represent only 3-5% of total transformer cost, their quality directly impacts the 20-30 year operational lifespan. Our value engineering approach demonstrates that investing in premium insulating cardboard can reduce total cost of ownership by 15-20% through decreased maintenance and extended replacement intervals. Financial evaluators should consider not just the initial transformer insulation parts processing equipment price, but also the material's energy efficiency (affecting operating costs) and scrap rates during manufacturing (typically 2-5% for quality materials versus 8-12% for inferior grades).

Compliance and Certification: Meeting Global Standards

As a leading transformer insulation parts processing equipment manufacturer in China serving global markets, we ensure our insulating cardboard meets all relevant international standards. Quality managers should verify certifications including IEC 60641, IEEE Std C57.12.00, and UL recognition for materials used in North American markets. Our products consistently exceed the flammability requirements of IEC 60707 (HB classification) and demonstrate superior performance in corrosive gas tests per ASTM D2303. For projects requiring specific regional approvals (such as GOST-R for Russian Federation or BIS for India), we maintain complete documentation packages to streamline your certification process.

Essential Certifications Checklist

- IEC 60641-3 for pressboard and presspaper

- RoHS and REACH compliance documentation

- Fire safety certifications (UL94, IEC 60707)

- Material Safety Data Sheets (MSDS)

- Country-specific electrical safety approvals

Conclusion: Partnering for Optimal Transformer Performance

Selecting the ideal insulating cardboard for transformer cores requires careful evaluation of material properties, electrical performance, mechanical durability, cost efficiency, and regulatory compliance. As specialists in transformer insulation components with 15+ years of industry experience, Gaomi Hongxiang Electromechanical Technology Co., Ltd. provides comprehensive solutions tailored to your specific voltage class, environmental conditions, and operational requirements. Our cost-effective transformer insulation parts processing equipment combines German engineering precision with competitive pricing, delivering exceptional value for utilities, OEMs, and service providers worldwide.

Contact our technical team today to request your customized transformer insulation solution, including detailed specifications, testing reports, and competitive pricing for your project volume. Let's collaborate to enhance your transformer reliability and efficiency through superior insulating materials.

NAVIGATION

MESSAGE

Request A Quote?