0000-00

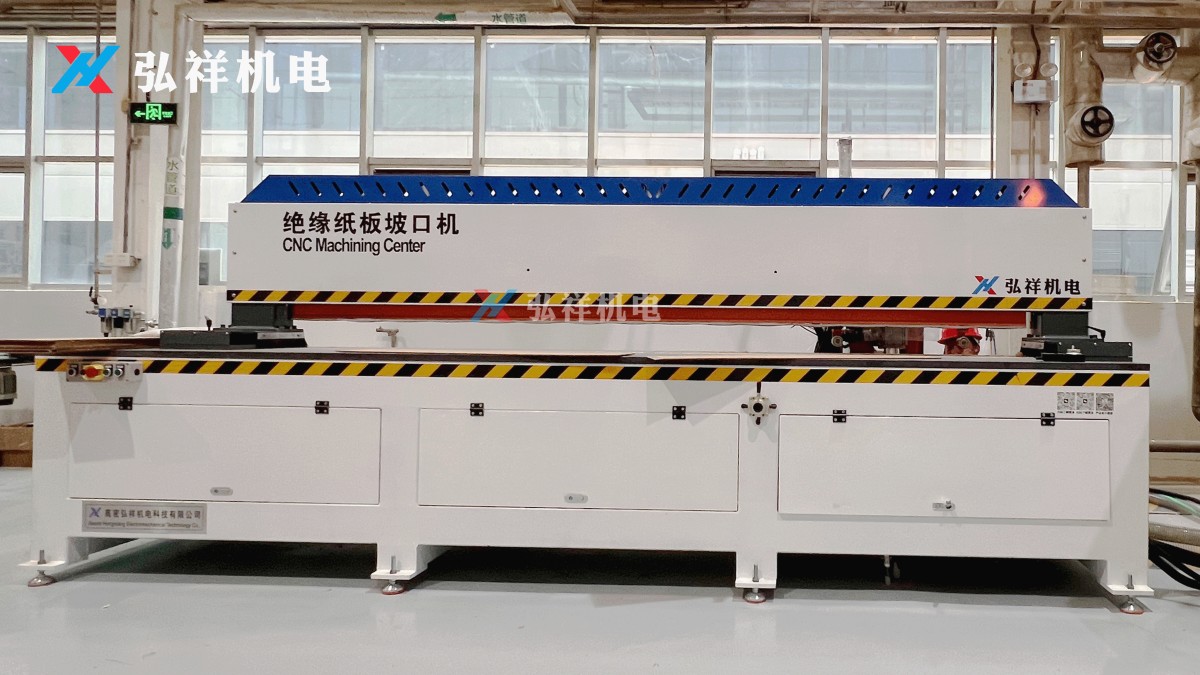

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board.

Key Components of a High-Quality Transformer Core

The transformer core is the heart of any heavy machinery transformer, responsible for efficient energy transfer and minimal energy loss. High-quality cores are typically made from grain-oriented silicon steel, which offers low hysteresis loss and high permeability. The core's laminations must be precisely cut and stacked to minimize eddy current losses. Advanced manufacturing techniques, such as those employed by Gaomi Hongxiang Electromechanical, ensure tight tolerances and uniform thickness across all laminations. Additionally, the use of high-grade insulating materials between laminations prevents short circuits and enhances durability. For applications requiring extreme precision, our Automatic four-sided chamfering machine ensures perfect edge finishing on core components.

Technical Performance and Industry Standards

When evaluating transformer cores for heavy machinery, several technical parameters are critical. These include core loss (measured in watts per kilogram), permeability, and saturation flux density. Industry standards such as IEC 60404 and ASTM A876 define the quality benchmarks for electrical steel used in transformer cores. Gaomi Hongxiang Electromechanical adheres to these international standards, ensuring that our transformer cores meet the highest performance criteria. Our Custom transformer insulation parts processing equipment is designed to handle the rigorous demands of heavy machinery, providing consistent performance under varying load conditions. The integration of advanced insulation materials, such as Nomex and epoxy resins, further enhances the thermal and electrical stability of our cores.

Procurement and Cost Considerations

For procurement specialists and financial evaluators, understanding the total cost of ownership (TCO) is essential. While high-quality transformer cores may have a higher initial cost, their superior efficiency and durability result in significant long-term savings. Factors such as energy efficiency, maintenance requirements, and lifespan should be weighed against upfront costs. Gaomi Hongxiang Electromechanical offers competitive pricing without compromising on quality, making our transformer cores a cost-effective choice for global customers. Our expertise in Transformer insulation parts processing equipment manufacturing allows us to provide tailored solutions that meet specific operational and budgetary needs.

Why Choose Gaomi Hongxiang Electromechanical?

With decades of experience in the industry, Gaomi Hongxiang Electromechanical has established itself as a trusted partner for transformer core solutions. Our commitment to innovation and quality is reflected in our extensive product range, which includes Custom transformer insulation parts processing equipment and advanced insulating materials. We serve a diverse clientele across Southeast Asia, South America, India, Pakistan, Russia, and beyond. Our integrated approach—combining R&D, production, and after-sales support—ensures that customers receive comprehensive solutions tailored to their needs. Whether you're a project manager or a technical evaluator, partnering with us guarantees access to cutting-edge technology and unparalleled expertise in transformer core manufacturing.

NAVIGATION

MESSAGE

Request A Quote?