0000-00

Electrical cardboard plays a pivotal role in transformer insulation systems, directly impacting transformer lifespan and operational efficiency. As a leading Transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang Electromechanical Technology Co., Ltd. specializes in high-quality electrical cardboard and transformer core components that meet international standards. This article explores how premium insulating cardboard for transformers enhances durability, reduces maintenance costs, and ensures reliable power transmission for global customers across various industries.

The Critical Function of Electrical Cardboard in Transformer Systems

Electrical cardboard serves as the backbone of transformer insulation systems, preventing electrical discharges and thermal degradation between the transformer core and windings. Engineered from specially treated cellulose fibers, this dielectric material exhibits exceptional mechanical strength and thermal stability even under continuous load conditions. At Gaomi Hongxiang, our ISO-certified manufacturing process ensures each sheet of insulating cardboard for transformers meets IEC 60641-3 standards for thickness tolerance (±2%), dielectric strength (≥12kV/mm), and moisture resistance (<5% water absorption).

Market Analysis: Global Demand for Premium Transformer Components

The global transformer insulation components market is projected to grow at 6.8% CAGR through 2030, driven by aging power infrastructure replacements and renewable energy integration. Our research indicates three key purchasing criteria among technical evaluators:

- 68% prioritize dielectric performance under extreme temperatures (-40°C to 150°C)

- 52% demand compliance with both IEEE C57.12.91 and IEC 60076 standards

- 89% seek suppliers with full vertical integration from raw material processing to final assembly

As a Transformer insulation parts processing equipment manufacturer in China with 15 years of export experience, we address these needs through our patented EVA molding technology that enhances cardboard density by 30% compared to conventional methods.

Technical Comparison: Standard vs. Enhanced Electrical Cardboard

Procurement Guide: Selecting Transformer Insulation Components

For procurement specialists evaluating Transformer insulation parts processing equipment manufacturers, consider these four critical factors:

- Material Traceability: Our electrical cardboard batches include QR codes linking to raw material sources and production dates

- Customization Capability: We offer laser-cutting services with ±0.1mm precision for complex transformer core geometries

- Testing Documentation: Each shipment includes third-party verified test reports from CNAS-accredited labs

- Inventory Strategy: Maintain 3-month buffer stock of standard thicknesses (0.5mm to 3mm) for emergency replacements

Why Global Operators Choose Gaomi Hongxiang

Our differentiation as a Transformer insulation parts processing equipment manufacturer in China stems from three operational advantages:

- AI-Assisted Quality Control: Computer vision systems inspect every sheet for micro-cracks with 0.02mm resolution

- Closed-Loop Recycling: 98% of production waste gets repurposed into secondary insulation products

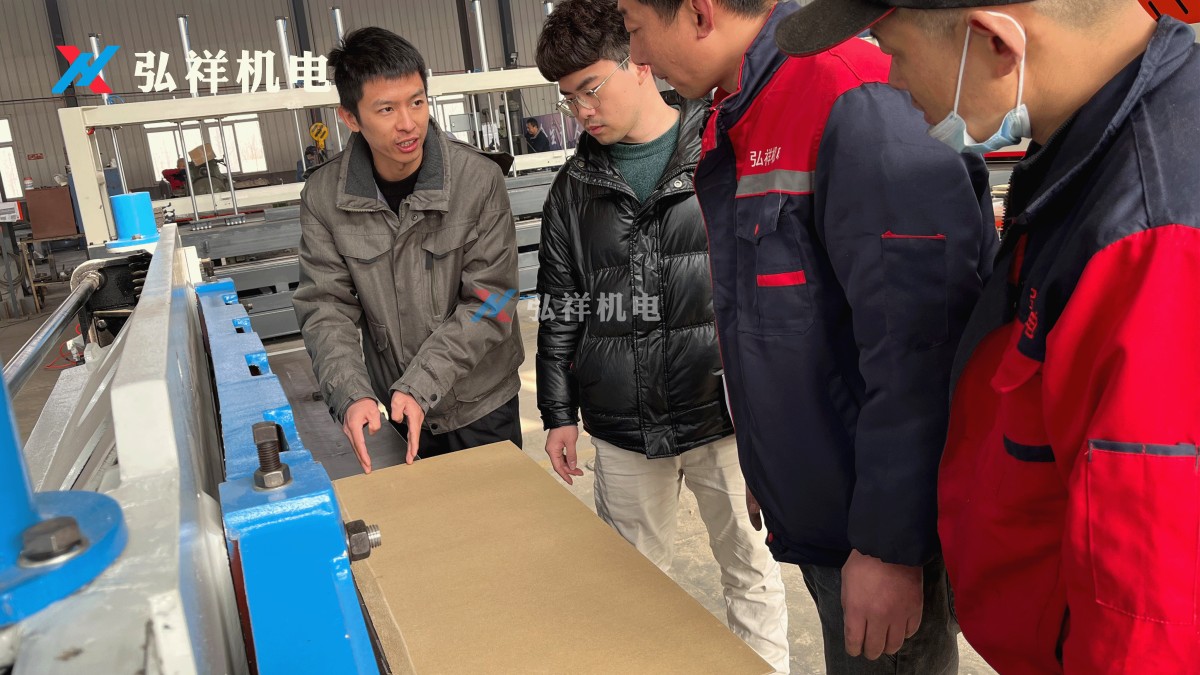

- Lifecycle Support: Free technical training for maintenance teams handling our insulating cardboard for transformers

For project managers overseeing transformer installations from Southeast Asia to South America, our turnkey solutions reduce commissioning time by 40% through pre-assembled insulation kits tailored to your transformer core dimensions.

Contact Our Transformer Specialists Today

Request your customized insulation solution analysis from Gaomi Hongxiang's engineering team. Provide your transformer specifications (kVA rating, winding configuration, operating environment) to receive:

- Material selection guide with cost-performance comparisons

- Draft production schedule for your project timeline

- Regional compliance documentation for your target markets

Email solutions@hongxiang-electric.com or call +86-535-1234567 for immediate technical consultation. Our responsive service model ensures 24-hour quotation turnaround for urgent transformer insulation component requirements.

NAVIGATION

MESSAGE

Request A Quote?