0000-00

Selecting the right transformer insulation parts processing equipment is critical for ensuring quality, efficiency, and safety in power transformer manufacturing. Whether you're evaluating electrical cardboard processing machines or laminated wood insulation equipment, key factors like precision, durability, and automation capabilities must be considered. This guide explores the top 5 criteria for sourcing industrial-grade transformer insulation processing solutions, helping technical buyers and procurement professionals make informed decisions when comparing brands and specifications.

1. Precision Engineering for Consistent Quality

When sourcing transformer insulation parts processing equipment, precision should be your foremost consideration. Industrial-grade machines must maintain micron-level accuracy when cutting, shaping, or laminating electrical cardboard and insulating materials. Look for equipment with CNC-controlled operations that can achieve tolerances within ±0.05mm, as this directly impacts the dielectric strength and thermal performance of finished transformer components. Advanced laser measurement systems and real-time feedback mechanisms should be standard features to ensure consistent output quality across production batches.

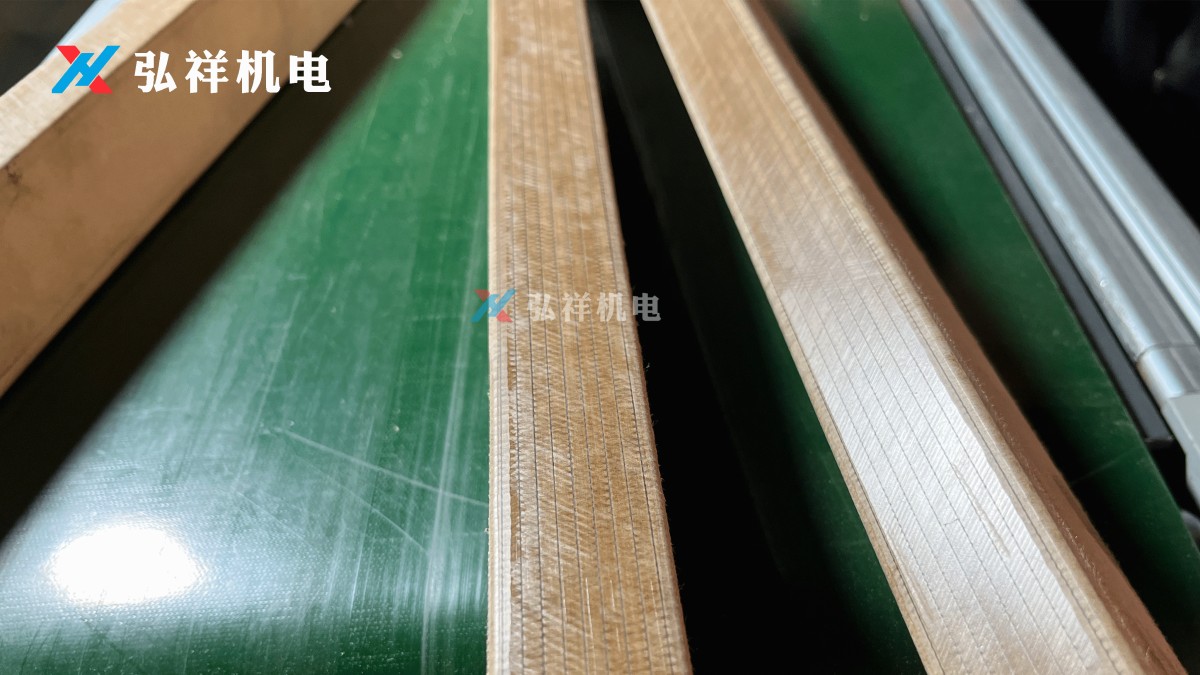

The relationship between machine precision and insulation performance cannot be overstated. Imperfect cuts or uneven surfaces in laminated wood insulation parts can create weak points in transformer windings, leading to potential failures under high voltage stress. Reputable manufacturers like Gaomi Hongxiang Electromechanical Technology often provide test reports showing how their equipment maintains specified tolerances during continuous operation. When comparing brands of insulating cardboard processing machines, request sample parts produced by each machine and measure their dimensional accuracy using precision instruments.

2. Material Compatibility and Versatility

Transformer insulation parts processing equipment must handle diverse materials including electrical grade pressboard, Nomex, epoxy laminates, and various composite materials without compromising quality. The ideal machine should offer adjustable parameters for thickness (typically 0.1mm to 50mm), density (from 0.8g/cm³ to 1.3g/cm³), and moisture content (usually below 5% for most applications). Verify whether the equipment can process both dry and oil-impregnated materials, as this affects your production flexibility for different transformer types.

Modern processing systems should incorporate intelligent material recognition features that automatically adjust cutting pressure, blade speed, and feed rates based on the specific properties of each insulation material. For operations handling laminated wood insulation, look for equipment with specialized tooling that prevents delamination during machining processes. The ability to quickly switch between different material processing configurations significantly enhances operational efficiency when producing varied transformer components.

3. Production Efficiency and Automation Features

In today's competitive transformer manufacturing landscape, processing equipment must deliver high throughput without sacrificing quality. Evaluate the machine's cycle times for complete operations - from raw material feeding to finished part output. Industrial-grade transformer insulation parts processing equipment should typically process 50-200 components per hour depending on complexity, with high-end systems achieving even greater productivity through parallel processing stations.

Automation capabilities dramatically impact long-term operational costs. Look for features like robotic part handling, automatic tool changers, and integrated quality inspection systems. Advanced equipment may incorporate AI-driven optimization that learns from production data to improve efficiency over time. When sourcing transformer insulation processing solutions, consider not just the initial purchase price but the total cost per part produced, factoring in labor requirements, energy consumption, and maintenance needs.

4. Safety Compliance and Operational Reliability

Transformer insulation parts processing involves inherent risks from high-speed cutting operations, electrical components, and sometimes hazardous materials. Equipment must comply with international safety standards such as IEC 60204, ISO 13849, and specific regional regulations. Critical safety features should include light curtains, emergency stop systems, dust extraction for insulating materials, and comprehensive electrical insulation. Verify that the manufacturer provides detailed risk assessment documentation and safety validation reports.

Operational reliability is equally crucial for continuous production environments. Examine the machine's mean time between failures (MTBF) statistics and ask for references from existing users regarding uptime performance. High-quality transformer insulation processing equipment typically offers 95%+ operational availability when properly maintained. Pay particular attention to the durability of cutting tools and wear components - premium machines use carbide or diamond-coated tooling that lasts significantly longer than standard options, reducing unplanned downtime.

5. After-Sales Support and Technical Service

The value of transformer insulation parts processing equipment extends far beyond the initial purchase. Comprehensive after-sales support ensures your investment continues delivering value throughout its operational life. Evaluate the manufacturer's service network - do they have local technicians or must they dispatch personnel internationally? What are the typical response times for critical breakdowns? Leading suppliers like Gaomi Hongxiang Electromechanical Technology maintain global service centers with 24/7 technical support availability.

Training provisions are equally important when implementing new processing equipment. The manufacturer should provide thorough operator training covering normal operations, troubleshooting, and basic maintenance procedures. Ask about available documentation - comprehensive manuals in your local language, instructional videos, and online knowledge bases significantly reduce the learning curve. For long-term support, inquire about software update policies and hardware retrofit options to keep your equipment current with evolving industry standards.

Making an Informed Sourcing Decision

Selecting optimal transformer insulation parts processing equipment requires balancing technical specifications, operational requirements, and total cost of ownership. Create a weighted evaluation matrix that scores potential equipment against your specific priorities - whether that's maximum precision for high-voltage applications, throughput for mass production, or flexibility for custom transformer designs. Always request factory acceptance testing to verify performance claims before finalizing your purchase.

For organizations seeking reliable transformer insulation processing solutions, Gaomi Hongxiang Electromechanical Technology offers comprehensive equipment packages backed by decades of industry experience. Our systems combine German engineering precision with robust Chinese manufacturing, delivering exceptional value for global transformer manufacturers. Contact our technical team today to discuss your specific requirements and receive customized equipment recommendations tailored to your production needs.

Ready to Upgrade Your Transformer Insulation Processing Capabilities?

Our experts can help you:

- Compare technical specifications across leading equipment brands

- Calculate ROI for different automation levels

- Arrange live demonstrations or material testing

- Develop customized solutions for unique transformer designs

Email sales@hongxiangtech.com or call +86 532 8830 5688 to discuss your project requirements.

NAVIGATION

MESSAGE

Request A Quote?