0000-00

Selecting the right transformer insulation parts processing equipment is critical for power transformer manufacturers and procurement teams. This comprehensive buyer's guide explores key considerations when sourcing industrial-grade equipment for processing electrical cardboard, laminated wood, and other insulation components. Learn how to evaluate different brands of insulating materials and machinery to ensure optimal performance, safety, and cost-efficiency in your transformer production line.

Understanding Transformer Insulation Parts Processing Equipment

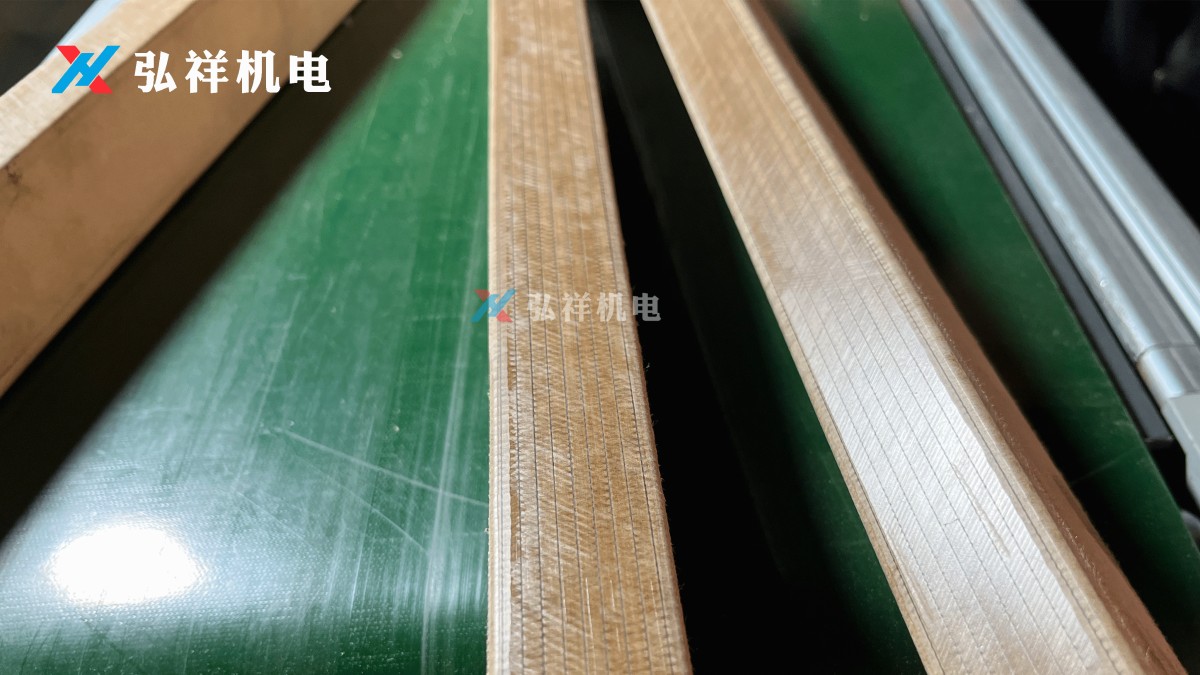

Transformer insulation parts processing equipment forms the backbone of power transformer manufacturing, ensuring the precise fabrication of critical components like electrical cardboard, laminated wood, and other insulating materials. These specialized machines must meet stringent industry standards while delivering consistent performance across diverse production environments. For procurement teams and technical evaluators, understanding the core functionalities of this equipment is the first step toward making informed purchasing decisions.

Industrial-grade transformer insulation processing systems typically include several key components: precision cutting machines for electrical cardboard, CNC-controlled laminating equipment for insulation wood, and specialized molding presses for EVA components. Each machine must maintain micron-level accuracy to ensure proper dielectric properties in the finished transformer. The equipment's ability to handle various material thicknesses - from 0.5mm to 50mm - while maintaining dimensional stability is crucial for meeting international standards like IEC 60641 and ASTM D350.

Key Technical Specifications to Evaluate

When comparing transformer insulation parts processing equipment, technical specifications provide the foundation for objective evaluation. Procurement teams should pay particular attention to these critical parameters:

- Cutting Precision: Look for equipment with ±0.05mm tolerance for electrical cardboard processing

- Production Capacity: Evaluate throughput rates (typically 200-500 sheets/hour for mid-range machines)

- Material Compatibility: Verify the machine handles your specific insulation materials (NOMEX, pressboard, etc.)

- Automation Level: Consider PLC control systems for consistent quality and reduced operator error

- Safety Features: Essential protections include emergency stops, thermal monitoring, and dust extraction

Comparative Analysis of Insulating Material Processing Solutions

The market offers diverse solutions for processing transformer insulation materials, each with distinct advantages for specific applications. A thorough comparison should consider both technical capabilities and operational economics. For electrical cardboard processing, rotary die-cutters provide excellent precision for complex shapes, while hydraulic presses dominate in laminated wood production due to their superior pressure control.

When evaluating different brands of insulating cardboard processing equipment, consider these factors:

Total Cost of Ownership Considerations

Beyond the initial purchase price, procurement teams must evaluate the total cost of ownership (TCO) for transformer insulation parts processing equipment. This comprehensive assessment should include:

- Energy consumption per production cycle

- Maintenance requirements and spare parts availability

- Operator training needs

- Expected equipment lifespan (typically 10-15 years for quality machines)

- Downtime costs and service response times

Safety and Compliance in Insulation Processing

Transformer insulation parts processing equipment must comply with numerous international safety and quality standards. For procurement teams and safety managers, verifying compliance with these regulations is non-negotiable:

Key standards include IEC 60204 for electrical safety of machinery, ISO 12100 for risk assessment, and specific local regulations like OSHA in the United States or CE marking in Europe. Premium equipment often exceeds these minimum requirements with additional safety features such as light curtains, pressure-sensitive mats, and redundant braking systems.

Future-Proofing Your Investment

With rapid advancements in transformer technology, forward-looking procurement teams should consider equipment that can adapt to future requirements:

- Modular designs allowing for future upgrades

- Compatibility with emerging insulation materials

- Industry 4.0 connectivity for smart factory integration

- Software-upgradable control systems

Conclusion and Next Steps

Selecting optimal transformer insulation parts processing equipment requires balancing technical specifications, operational requirements, and total cost considerations. By thoroughly evaluating equipment capabilities against your specific production needs, you can ensure long-term reliability and efficiency in your transformer manufacturing process.

Gaomi Hongxiang Electromechanical Technology Co., Ltd. offers comprehensive solutions for transformer insulation parts processing, combining cutting-edge technology with decades of industry experience. Our equipment meets the highest international standards while delivering exceptional value. Contact our engineering team today to discuss your specific requirements and receive a customized equipment recommendation.

NAVIGATION

MESSAGE

Request A Quote?