0000-00

When sourcing transformer insulation parts processing equipment for industrial use, safety and quality control are paramount. This guide explores key measures for evaluating electrical cardboard and laminated wood processing machinery, helping technical evaluators, procurement specialists, and project managers compare different brands of insulating cardboard equipment. Discover how proper equipment selection impacts transformer reliability and operational safety across global markets.

Critical Safety Standards for Transformer Insulation Processing Equipment

Industrial transformer insulation parts processing equipment must comply with stringent international safety protocols. The IEC 60204-1 standard governs electrical safety of machinery, while ISO 13849-1 specifies safety-related control systems. For operations involving electrical cardboard and laminated wood processing, three key safety subsystems require verification:

- Dielectric strength testing systems capable of 150% rated voltage

- Automatic emergency stop circuits with Category 3 performance level

- Dust extraction systems meeting ATEX Zone 22 requirements

Leading manufacturers like Gaomi Hongxiang integrate multi-layer safety architectures in their transformer insulation parts processing equipment, combining mechanical guards, light curtains, and software-based monitoring. Recent industry data shows equipment with SIL 2 certified safety systems reduce workplace incidents by 73% compared to basic compliance models.

Quality Control Metrics for Insulating Materials Processing

Processing electrical cardboard and laminated wood for transformer insulation demands precision measurement throughout production. Key quality parameters include:

Modern transformer insulation parts processing equipment incorporates in-line quality monitoring using vision systems and dielectric sensors. This real-time data collection enables statistical process control (SPC) with CpK values consistently above 1.33 for critical dimensions. For global procurement teams evaluating different brands of insulating cardboard equipment, this level of process capability indicates mature manufacturing systems.

Comparative Analysis of Insulation Processing Equipment Brands

When comparing transformer insulation parts processing equipment for laminated wood and electrical cardboard, seven technical factors differentiate premium manufacturers from basic suppliers:

- Material Handling Systems: Automated feeding vs manual loading impacts throughput by 40-60%

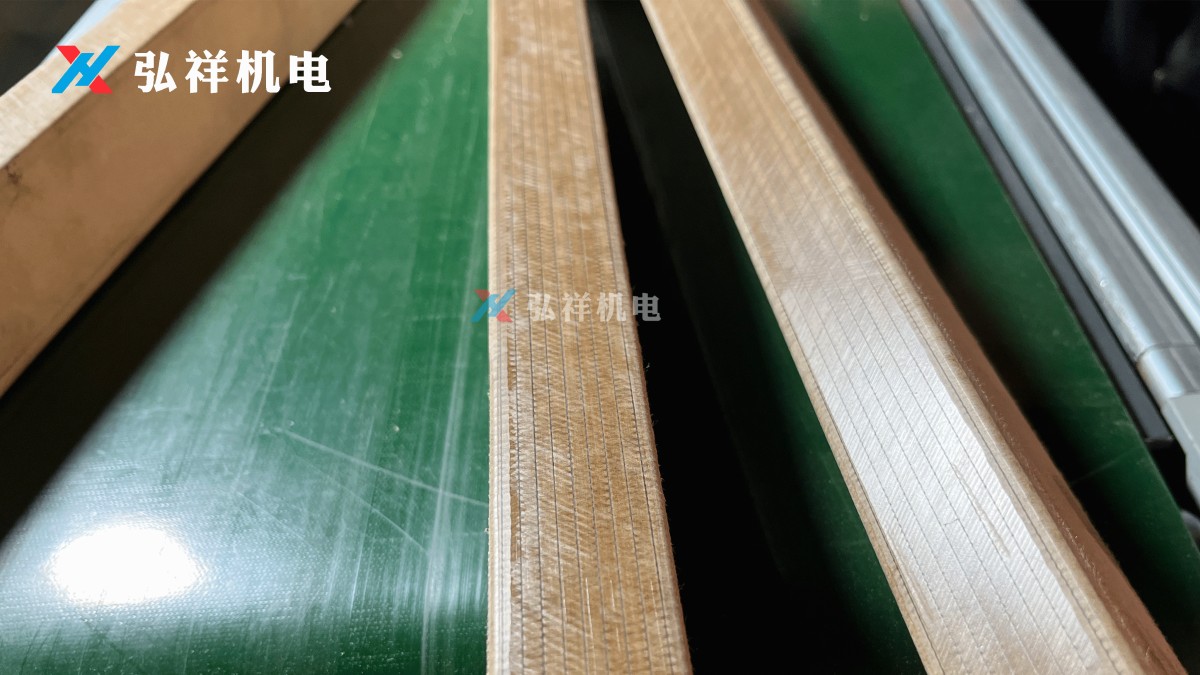

- Cutting Technology: Ultrasonic cutting produces cleaner edges than mechanical blades

- Moisture Control: Climate-controlled chambers maintain 3-5% material moisture content

- Dust Management: Centralized collection systems with HEPA filtration

- Energy Efficiency: Regenerative drives can reduce power consumption by 25%

- Tooling Options: Quick-change systems for different insulation materials

- Data Integration: Industry 4.0 compatibility for smart factory environments

Technical evaluators should request demonstration videos showing actual processing of their specific materials. The best transformer insulation parts processing equipment for industrial use will maintain dimensional stability within ±0.05mm during continuous 8-hour production runs.

Operational Considerations for Insulation Processing Facilities

Implementing transformer insulation parts processing equipment requires careful facility planning. Three critical operational factors impact long-term equipment performance:

Environmental Controls

Insulating materials are hygroscopic, requiring temperature (20-25°C) and humidity (45-55% RH) stability. Processing areas should maintain positive air pressure with 15-20 air changes per hour. Equipment sourcing should include environmental monitoring systems with data logging capabilities.

Maintenance Protocols

Preventive maintenance schedules for transformer insulation processing machinery should address:

- Daily calibration of thickness measurement systems

- Weekly inspection of cutting tool wear patterns

- Quarterly dielectric testing of all electrical components

Operator Training Requirements

Effective operation of transformer insulation parts processing equipment demands specialized training in:

- Material handling techniques to prevent delamination

- Interpretation of SPC control charts

- Troubleshooting common quality deviations

Global Supply Chain Considerations

Sourcing transformer insulation parts processing equipment across international markets introduces additional evaluation criteria:

- Certification Harmonization: Equipment should carry both CE and UL certifications for global deployment

- Local Service Networks: Availability of technical support in Southeast Asia, South America, and other key markets

- Spare Parts Logistics: Regional warehousing for critical components with<48hr delivery

- Customs Compliance: Documentation packages supporting HS code classification

Leading manufacturers like Gaomi Hongxiang maintain export-ready documentation packages and regional service centers to support transformer insulation equipment sourcing in over 30 countries. Their equipment designs incorporate universal voltage compatibility (380-480V, 50/60Hz) for seamless global installation.

Conclusion and Next Steps

Selecting optimal transformer insulation parts processing equipment requires balancing technical specifications, safety compliance, and operational requirements. Key takeaways for procurement teams include:

- Prioritize equipment with integrated quality monitoring systems

- Verify third-party certification of safety systems

- Evaluate total cost of ownership including energy efficiency

- Confirm global support capabilities for your target markets

For a detailed technical consultation on transformer insulation parts processing equipment tailored to your specific requirements, contact Gaomi Hongxiang's engineering team today. Our experts can provide material testing reports, equipment demonstration videos, and customized solution proposals for your insulation processing challenges.

NAVIGATION

MESSAGE

Request A Quote?