0000-00

When sourcing transformer parts processing equipment, reliability is non-negotiable. As a leading Transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang delivers precision-engineered solutions for transformer core assembly and electrical cardboard fabrication. Our specialized equipment for manufacturing Transformer insulation components combines cutting-edge technology with stringent quality control, serving global clients across power generation and distribution sectors. Discover what sets trustworthy manufacturers apart in this critical industry.

Defining Quality in Transformer Parts Processing Equipment

The manufacturing of transformer core and insulation components demands equipment that meets exacting standards. A reliable Transformer insulation parts processing equipment manufacturer must demonstrate proficiency in handling materials like electrical insulating cardboard and laminated wood with micron-level precision. At Gaomi Hongxiang, our machines are engineered to produce components that comply with IEC 60076 and IEEE C57 standards, ensuring compatibility with global power infrastructure. Key differentiators include adaptive control systems for thickness variation compensation in electrical cardboard processing and AI-assisted alignment for transformer core stacking.

Market Overview: The Growing Demand for Precision Equipment

The global transformer market, projected to reach $96.3 billion by 2030 according to Grand View Research, creates parallel demand for specialized processing equipment. Our analysis identifies three critical trends: 1) 28% annual growth in renewable energy transformer requirements, 2) increased need for high-temperature resistant insulation components, and 3) rising automation in transformer core assembly. As a China-based manufacturer with exports to 37 countries, we've adapted our Transformer insulation parts processing equipment to address these evolving needs through modular designs that accommodate both traditional mineral oil and biodegradable ester fluid insulation systems.

Technical Specifications That Matter

When evaluating Transformer insulation parts processing equipment, technical decision-makers should prioritize:

- Cutting Precision: Our equipment achieves ±0.02mm tolerance for electrical cardboard components

- Production Capacity: Ranging from 500 to 5,000 insulation components per shift

- Material Compatibility: Processes Nomex, pressboard, and EVA materials up to 15mm thickness

- Energy Efficiency: 30% reduction in power consumption versus conventional machines

- Safety Features: Integrated dust extraction and fire suppression systems

These parameters directly impact transformer performance metrics like partial discharge levels and thermal aging characteristics.

Procurement Guide: 7 Evaluation Criteria

For procurement teams comparing Transformer insulation parts processing equipment manufacturers, we recommend this assessment framework:

Why Gaomi Hongxiang Stands Apart

Our position as a premier Transformer insulation parts processing equipment manufacturer in China stems from three decades of focused innovation. Unlike generic machinery suppliers, we specialize exclusively in transformer component manufacturing systems. This specialization allows us to offer:

- Proprietary algorithms for transformer core stacking optimization

- In-house material science laboratory for insulation testing

- Custom software integration with ERP/MES systems

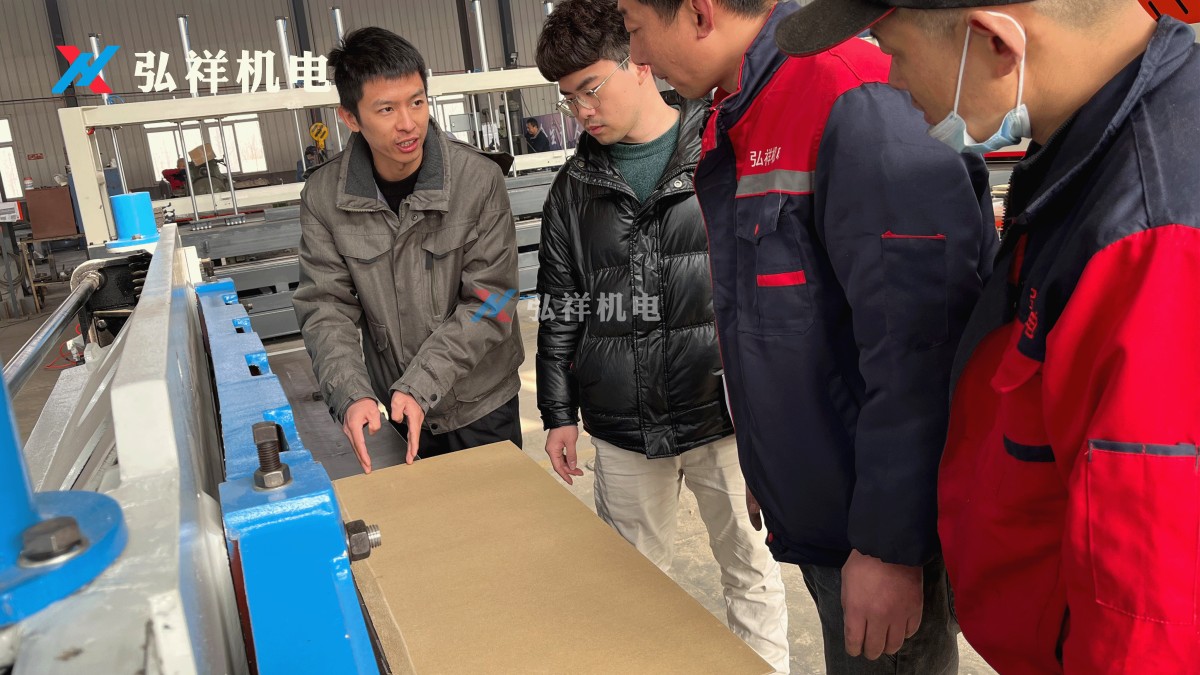

- On-site training programs certified by CNAS (China National Accreditation Service)

Recent installations in Pakistan's HV transformer plants and Russian renewable energy projects demonstrate our equipment's performance under extreme climatic conditions.

Addressing Common Industry Challenges

Transformer manufacturers frequently encounter these pain points with inferior equipment:

- Material Waste: Our adaptive cutting systems reduce electrical cardboard scrap by up to 22%

- Dimensional Inconsistency: Laser-guided alignment ensures ±0.05mm repeatability

- Downtime: Modular design allows component replacement in under 4 hours

- Safety Risks: Integrated sensors detect potential insulation material combustion

These solutions directly address the concerns of plant managers and safety officers.

Future-Ready Manufacturing Solutions

The transformer industry's evolution toward smart grids and eco-design directives requires equipment capable of:

- Processing biodegradable insulation materials

- Generating digital twins of manufactured components

- Interface with IIoT platforms for predictive maintenance

Our R&D roadmap focuses on these areas, with pilot installations already operational in India's smart city projects.

Your Next Steps

For technical teams evaluating Transformer insulation parts processing equipment, we recommend:

- Request our equipment specification dossier with third-party test reports

- Schedule a virtual demonstration of our EVA molding processing systems

- Arrange a sample processing trial with your specific materials

Contact our engineering team today to discuss how our solutions can optimize your transformer component manufacturing process while meeting your quality and budgetary requirements.

NAVIGATION

MESSAGE

Request A Quote?