0000-00

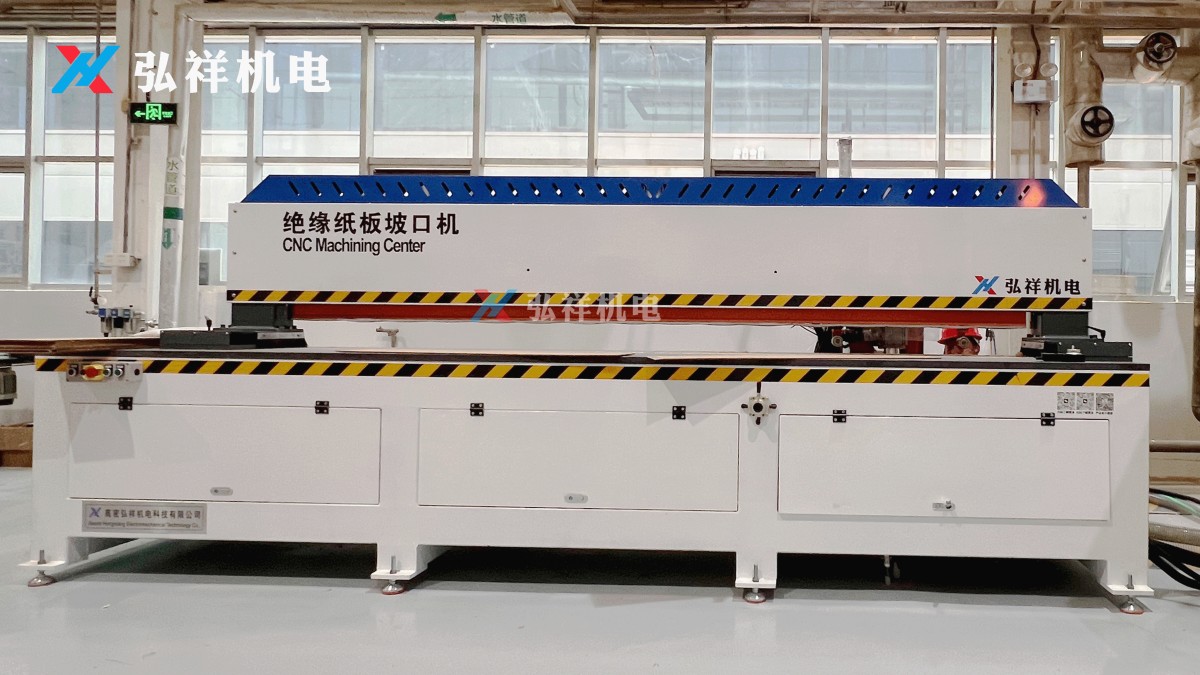

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board.

Key Considerations for Selecting a Transformer Insulation Parts Processing Equipment Manufacturer

Choosing the right manufacturer for transformer insulation parts processing equipment involves evaluating multiple factors to ensure the equipment meets your specific needs. Here are the critical aspects to consider:

- Technical Expertise: The manufacturer should have a proven track record in designing and producing high-quality transformer insulation parts processing equipment. Look for certifications such as ISO 9001, which indicate adherence to international quality standards.

- Customization Capabilities: The ability to provide Custom transformer insulation parts processing equipment tailored to your requirements is essential. This includes flexibility in design, material selection, and production processes.

- Advanced Technology: Modern manufacturing techniques, such as CNC machining and automated processes, ensure precision and efficiency. For example, our Automatic four-sided chamfering machine offers superior accuracy and speed for transformer core processing.

- Quality Control: Rigorous testing and inspection procedures are crucial to ensure the durability and performance of the equipment. Ask about the manufacturer's quality assurance protocols and testing facilities.

- After-Sales Support: Reliable technical support, maintenance services, and spare parts availability are vital for minimizing downtime and ensuring long-term operational efficiency.

Market Overview: Transformer Insulation Parts Processing Equipment in China

China has emerged as a global leader in the production of transformer insulation parts processing equipment, thanks to its advanced manufacturing infrastructure and competitive pricing. The demand for high-quality transformer core for heavy machinery and other components is growing, driven by the expansion of power infrastructure and renewable energy projects worldwide.

Gaomi Hongxiang Electromechanical Technology Co., Ltd. stands out in this competitive market by offering innovative solutions and comprehensive services. Our products, including electrical insulating cardboard, insulating laminated wood, and insulating parts, are widely used in power transformers and other heavy machinery applications. With a strong presence in domestic and international markets, we cater to clients in Southeast Asia, South America, India, Pakistan, Russia, and beyond.

Technical Performance and Standards

Transformer insulation parts processing equipment must meet stringent technical and safety standards to ensure reliable performance. Key parameters to evaluate include:

- Precision and Accuracy: Equipment should deliver consistent results with minimal tolerances, ensuring the integrity of transformer insulation parts.

- Material Compatibility: The ability to process various materials, such as electrical insulating cardboard and laminated wood, is essential for versatility.

- Energy Efficiency: Modern equipment should minimize energy consumption while maximizing output, reducing operational costs.

- Compliance with Standards: Look for equipment that adheres to international standards such as IEC, IEEE, and ANSI, ensuring compatibility and safety in global markets.

Why Choose Gaomi Hongxiang?

As a trusted Transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang offers unparalleled advantages:

- Integrated R&D and Production: Our in-house research and development team ensures continuous innovation and customization to meet evolving industry demands.

- Global Reach: With a robust export network, we serve clients across multiple regions, providing reliable equipment and support.

- Comprehensive Services: From installation and training to after-sales maintenance, we offer end-to-end solutions to ensure seamless operations.

- Proven Track Record: Our products are trusted by leading power transformer manufacturers worldwide, reflecting our commitment to quality and performance.

Contact Us for Your Custom Transformer Insulation Parts Processing Equipment Needs

Whether you're a procurement professional, technical evaluator, or project manager, Gaomi Hongxiang is your ideal partner for high-quality transformer insulation parts processing equipment. Contact us today to discuss your requirements and discover how our solutions can enhance your production efficiency and product quality.

NAVIGATION

MESSAGE

Request A Quote?