0000-00

Why China Leads in Transformer Insulation Parts Manufacturing?

The global transformer industry increasingly relies on Chinese manufacturers for high-precision insulation components. With decades of specialized experience, China has developed unmatched capabilities in producing transformer cores for heavy machinery and custom insulating parts. Gaomi Hongxiang Electromechanical exemplifies this technological leadership through:

- Advanced production facilities with ISO 9001-certified quality systems

- Vertical integration from material processing (EVA molding, insulating cardboard) to final assembly

- AI-enhanced manufacturing processes that ensure ±0.1mm dimensional accuracy

- 30% cost advantage over Western counterparts without compromising IEC 60076 standards

Technical Superiority in Transformer Core Production

Our Automatic four-sided chamfering machine represents the cutting edge in transformer core processing technology. This equipment enables:

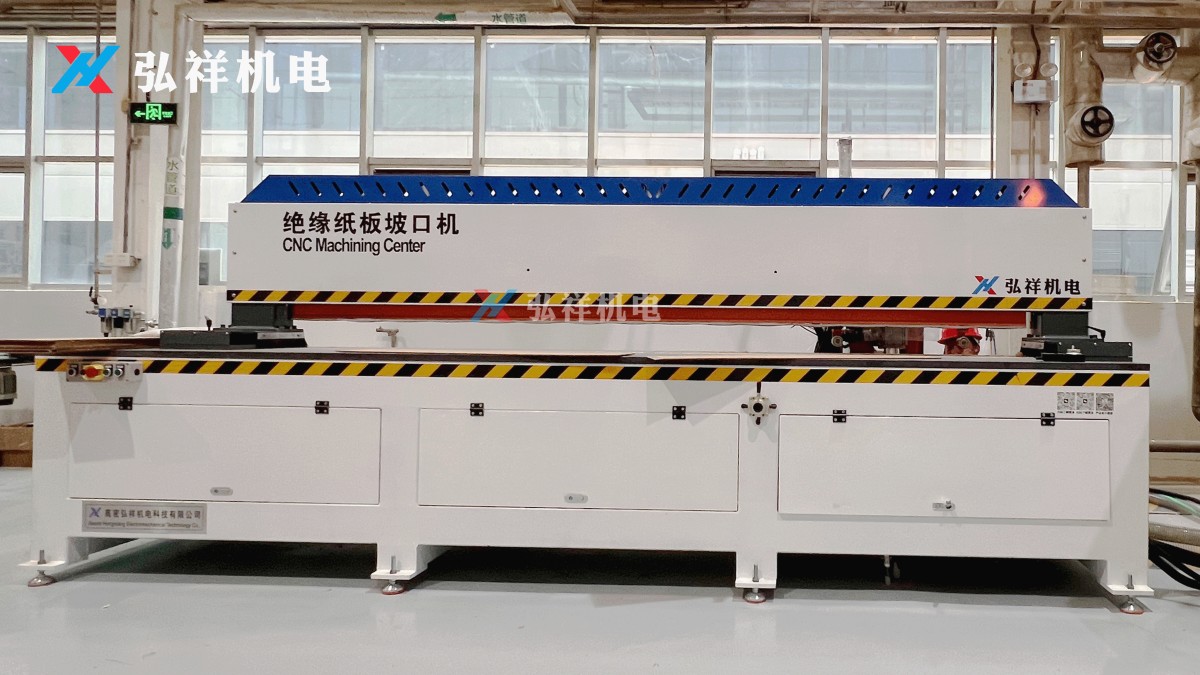

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board

Procurement Considerations for Global Buyers

When evaluating Transformer insulation parts processing equipment manufacturers in China, technical assessment teams should verify:

- Material Traceability: Full documentation from raw insulating laminated wood to finished components

- Testing Capabilities: In-house partial discharge measurement, impulse voltage tests

- Customization Flexibility: Ability to adapt designs for regional standards (IEEE, IEC, JIS)

- After-Sales Support: Multilingual technical documentation and remote diagnostic services

Cost-Benefit Analysis: China vs. Local Sourcing

For procurement teams weighing alternatives, Chinese manufacturers offer compelling advantages:

- 40-60% savings compared to European/American suppliers for equivalent transformer core quality

- Faster lead times (typically 4-6 weeks) due to complete supply chain integration

- Lower MOQs (minimum order quantities) for prototype development

- Dual-voltage compatibility for equipment destined for different markets

Why Partner with Gaomi Hongxiang Electromechanical?

As a full-service Transformer insulation parts processing equipment manufacturer, we distinguish ourselves through:

- AI-Driven Quality Control: Machine vision systems detect microscopic defects in insulating components

- Global Compliance: CE, UL, and GOST-R certified production lines

- Turnkey Solutions: From design consultation to installation training

- Proven Track Record: Successful deployments in 23 countries across power utilities, renewable energy, and industrial applications

For project managers requiring transformer cores for heavy machinery or custom insulation solutions, our engineering team stands ready to assist. Contact us today for a technical consultation and discover how our equipment can optimize your transformer manufacturing process.

NAVIGATION

MESSAGE

Request A Quote?