0000-00

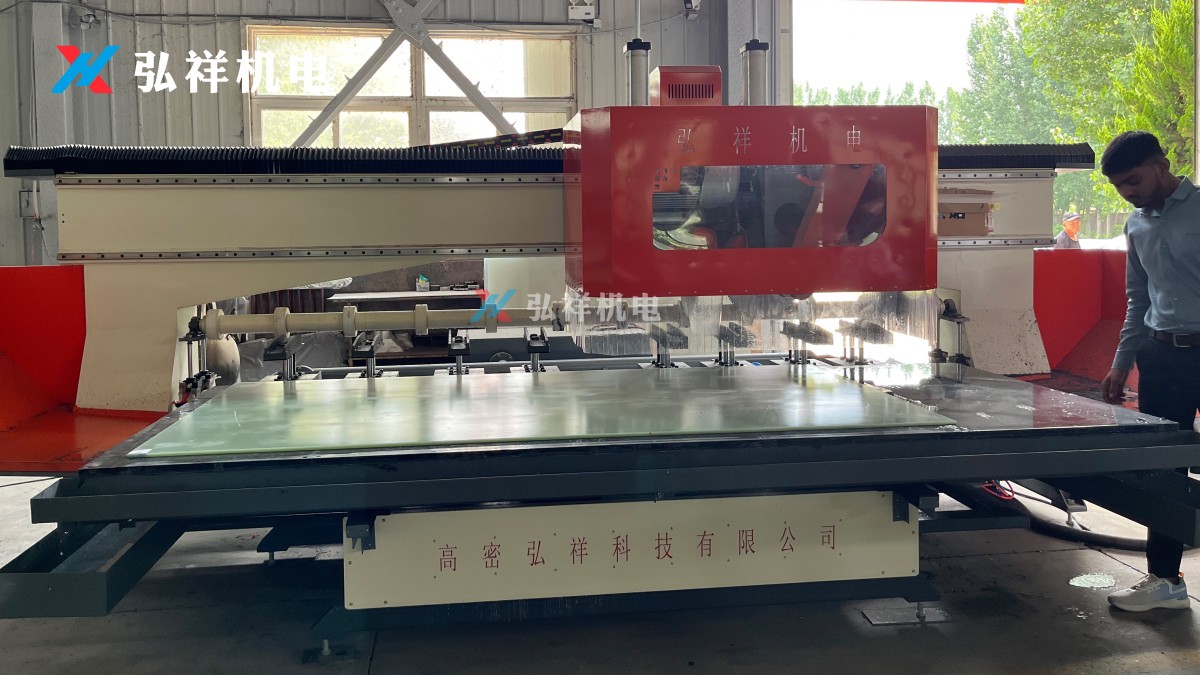

When sourcing transformer insulation parts processing equipment for EVA molding, laminated wood, or electrical insulation applications, reliable after-sales support is crucial for operational continuity. This guide explores what global buyers should expect from premium Chinese manufacturers like Gaomi Hongxiang - from CNC equipment OEM services to bulk order technical support. Discover how top suppliers ensure your transformer insulation production maintains peak performance through comprehensive maintenance, training, and responsive troubleshooting solutions.

Comprehensive Technical Support for Transformer Insulation Equipment

Investing in transformer insulation parts processing equipment requires long-term technical collaboration. Premium manufacturers provide dedicated engineering support for installation, calibration, and performance optimization of CNC machines handling EVA molding or laminated wood components. This includes:

- On-site or remote commissioning assistance for bulk order deliveries

- Process parameter optimization for electrical insulation materials

- Customized tooling recommendations for OEM service configurations

- Annual performance audits with efficiency improvement reports

Gaomi Hongxiang's technical teams maintain ISO 9001-certified response protocols, ensuring sourcing queries are resolved within 24 hours for critical production line issues.

Structured Training Programs for Equipment Operators

Proper operator training directly impacts the lifespan of transformer insulation processing equipment. Leading Chinese manufacturers deliver:

Training modules are available in multiple languages for export markets including Southeast Asia and South America, with VR simulations for complex procedures.

Predictive Maintenance Solutions

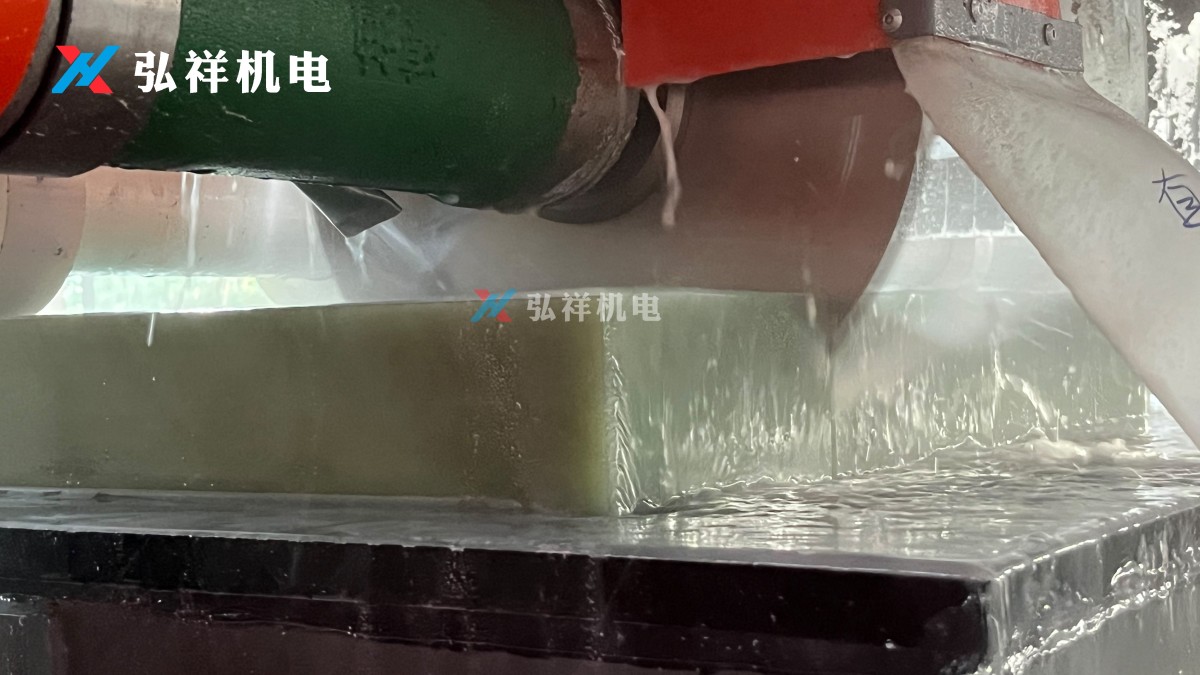

Modern transformer insulation parts processing equipment incorporates IoT-enabled predictive maintenance features. Key benefits include:

- Vibration analysis for CNC machining centers

- Thermal imaging of cutting tools for laminated wood processing

- Automated lubrication alerts for EVA molding presses

- Cloud-based performance benchmarking against industry standards

Manufacturers provide customized maintenance schedules based on actual equipment usage data from similar installations in Russia, India, and Pakistan.

Spare Parts Management Strategy

Efficient spare parts logistics minimize downtime for electrical insulation production. Top suppliers maintain:

- Regional warehouses in key export markets

- Critical parts inventory reserved for bulk order customers

- 3D printing capabilities for obsolete components

- Emergency air freight arrangements

Gaomi Hongxiang's automated inventory system guarantees 95% availability of common replacement parts for transformer insulation processing equipment.

Continuous Improvement Programs

Progressive manufacturers collaborate with clients on equipment upgrades:

- Retrofit packages for older CNC machines

- Energy efficiency optimization consultations

- Material waste reduction initiatives

- Technology transfer workshops

These programs help transformer insulation parts processing equipment maintain compliance with evolving international standards.

Why Choose Gaomi Hongxiang's After-Sales Support?

With 15+ years specializing in transformer insulation manufacturing solutions, we offer:

- Dedicated account managers for OEM service clients

- Multilingual technical documentation

- 24/7 support hotline with engineer escalation

- Performance-based service contracts

Ready to optimize your transformer insulation production with reliable after-sales support?

Contact our engineering team today to discuss customized service packages for your EVA molding, laminated wood, or electrical insulation processing requirements.

NAVIGATION

MESSAGE

Request A Quote?