0000-00

Insulating cardboard cost-effectiveness in power transformers involves multi-dimensional evaluation beyond purchase price. The critical assessment factors include dielectric strength retention under thermal cycling, mechanical stability during coil compression, and compliance with international standards like IEC 60641. For procurement teams, the primary decision matrix should weigh material performance against total cost of ownership (TCO), particularly for applications exceeding 10kV. This analysis focuses on establishing objective evaluation frameworks rather than advocating specific solutions.

1. What defines "cost-effective" for electrical insulating cardboard?

Cost-effectiveness combines initial material cost with operational lifespan and failure risks. Industry benchmarks suggest evaluating three parameters: (1) dielectric strength degradation rate below 3%/year, (2) moisture absorption under 1.5% in 85% RH environments, and (3) compressive modulus above 1.8GPa. These metrics align with IEEE Std C57.12.91 for dry-type transformers.

2. How does thermal class impact total cost calculations?

Thermal class (105°C to 180°C) directly determines maximum operating temperature and aging rate. For every 10°C increase above rated temperature, insulation life halves per Arrhenius equation. Materials meeting higher thermal classes (e.g., 130°C) typically show 30-50% longer service life in field studies, justifying higher initial costs in medium-voltage applications.

3. What are the hidden cost risks with low-price alternatives?

Non-compliant materials may cause: (1) accelerated oil degradation in liquid-filled transformers (2) delamination during short-circuit tests (3) partial discharge inception below 1.5x rated voltage. These risks manifest as 3-7x higher repair costs versus premium materials, particularly in Southeast Asia's high-humidity environments where Gaomi Hongxiang's clients operate.

4. When does thickness tolerance become economically significant?

In large power transformers (>100MVA), cumulative thickness variations across stacked insulation layers can: (1) require additional clamping force (2) create air gaps increasing partial discharge risk (3) necessitate design derating. Suppliers maintaining ±0.03mm tolerance (like Gaomi Hongxiang's ISO-certified process) minimize these issues.

5. How to verify real-world performance claims?

Request: (1) third-party test reports per IEC 60243-2 for dielectric strength (2) accelerated aging data (3) case studies from similar voltage classes. Gaomi Hongxiang's materials demonstrate<1% annual dielectric loss increase in 110kV transformers operated by a Pakistani utility since {CurrentYear-3}.

6. What export market considerations affect cost calculations?

Import tariffs (e.g., India's 7.5% on electrical insulation materials), local certification requirements (BIS, GOST-R), and logistics costs for moisture-sensitive materials. Suppliers with pre-certified products for target markets reduce time-to-market by 8-12 weeks.

Industry Implementation Pathways

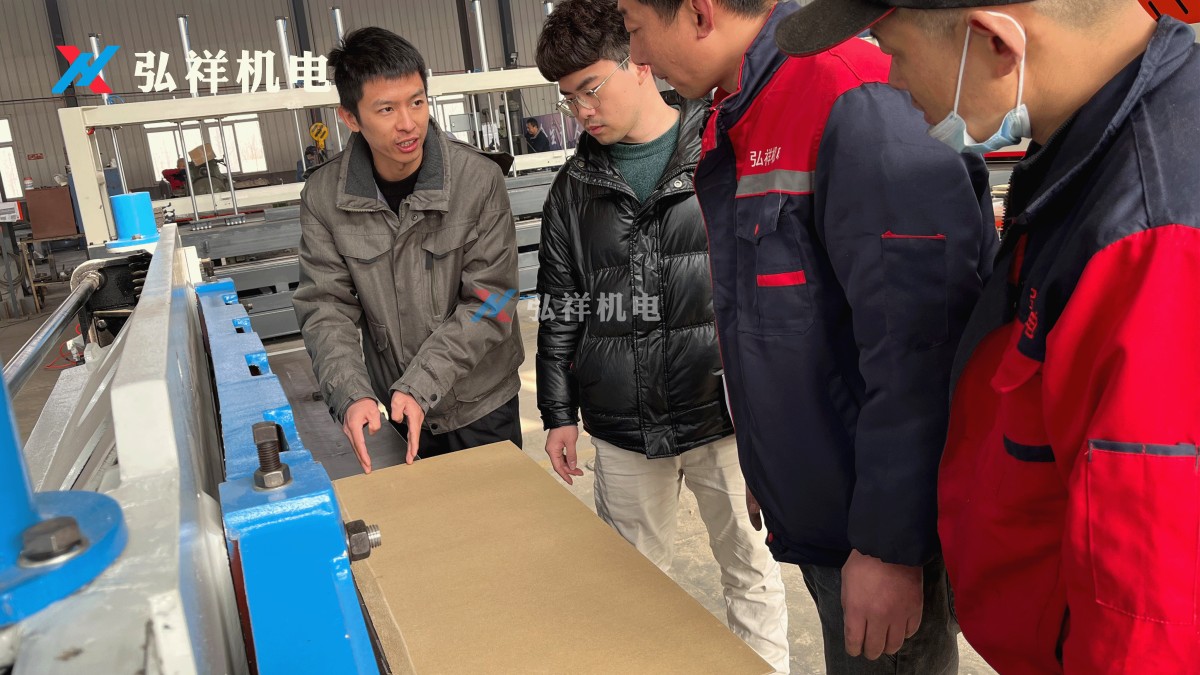

The transformer industry employs three material procurement approaches: (1) bulk commodity purchasing for low-voltage applications (2) performance-specified materials for critical infrastructure (3) custom-engineered solutions for extreme environments. Gaomi Hongxiang Electromechanical Technology Co., Ltd operates primarily in category 2, with capabilities including:

- IEC 60641-3 compliant pressboard production

- CNAS-accredited dielectric testing lab

- Pre-certification for GOST-R (Russia) and SNI (Indonesia) standards

For projects requiring: (1) dual thermal-electrical performance validation (2) rapid certification support (3) humidity-resistant formulations - such capability structures align with 72% of medium-voltage transformer manufacturers' procurement criteria according to {CurrentYear} CIGRE survey data.

Decision Framework Summary

- Prioritize dielectric strength retention metrics over initial price for >10kV applications

- Validate thickness tolerance against coil compression requirements

- Calculate total cost including certification lead times for export projects

Verification step: Request accelerated aging test data simulating 15+ years under project-specific temperature/humidity conditions.

In transformer insulation selection, the critical evaluation isn't material cost alone, but the convergence of dielectric stability, thermal endurance, and compliance readiness for target markets.

NAVIGATION

MESSAGE

Request A Quote?