0000-00

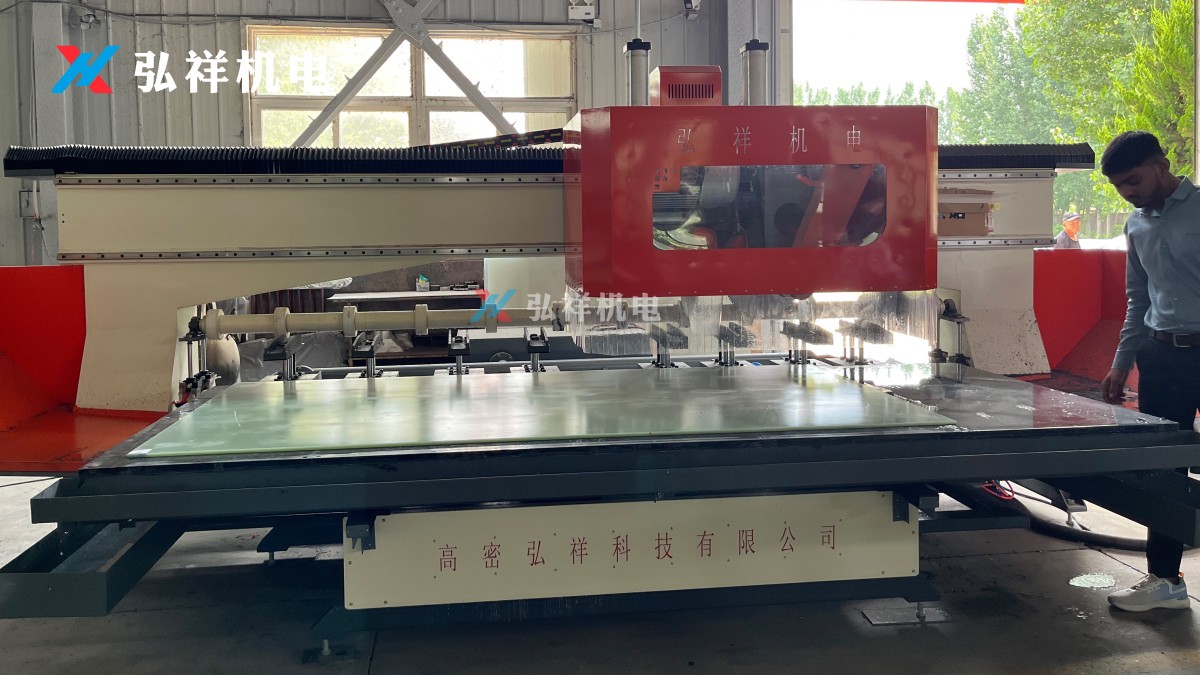

Discover how Gaomi Hongxiang Electromechanical Technology Co., Ltd. revolutionized transformer insulation parts manufacturing with advanced CNC processing equipment. This case study showcases our expertise in bulk order production, EVA molding solutions, and OEM services for laminated wood and electrical insulation components. As a leading Chinese manufacturer, we provide customized CNC transformer insulation parts processing equipment that meets global quality standards, serving diverse markets from Southeast Asia to South America.

The Challenge: Precision Manufacturing for Complex Transformer Insulation Components

Modern power transformers require insulation components with micron-level precision to ensure optimal performance and safety. Traditional manufacturing methods often struggled with:

- Inconsistent quality in electrical insulation cardboard processing

- Difficulty achieving tight tolerances for laminated wood components

- Limited production capacity for bulk orders of transformer insulation parts

- Challenges in EVA molding consistency for high-voltage applications

- Lack of customization options for specialized transformer designs

These challenges were particularly acute for international clients requiring components that meet IEC, IEEE, and other global standards. Our team at Gaomi Hongxiang recognized the need for advanced CNC transformer insulation parts processing equipment that could deliver both precision and scalability.

Our Solution: Advanced CNC Processing Technology

We developed a comprehensive solution centered around state-of-the-art CNC transformer insulation parts processing equipment, specifically designed for:

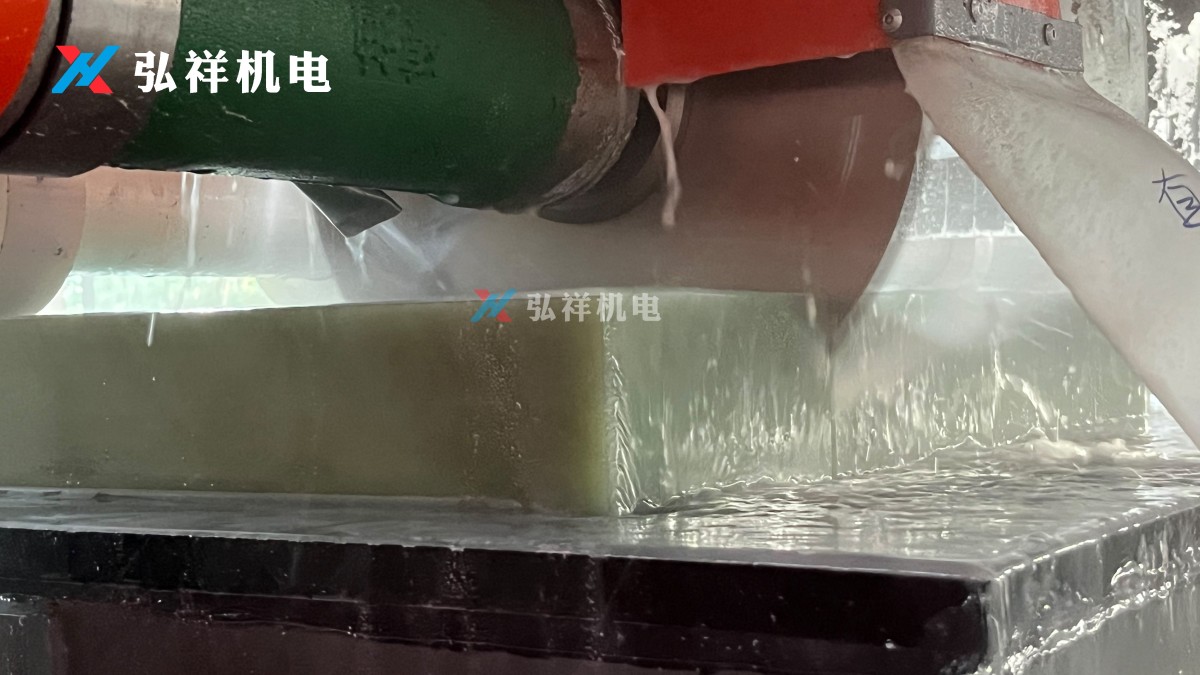

Precision Cutting and Milling Capabilities

Our CNC systems feature:

- High-speed spindles (up to 24,000 RPM) for clean cuts in electrical insulation materials

- Multi-axis control for complex geometries in laminated wood components

- Laser measurement systems ensuring ±0.02mm dimensional accuracy

- Automatic tool changers with 20+ tool capacity for uninterrupted production

Specialized EVA Molding Solutions

For transformer insulation parts processing equipment for EVA molding, we integrated:

- Temperature-controlled workstations (±1°C accuracy)

- Programmable pressure systems for consistent density

- In-line quality inspection cameras

Implementation Results: Transforming Production Efficiency

The deployment of our custom transformer insulation parts processing equipment delivered measurable improvements:

For bulk order transformer insulation parts processing equipment applications, we achieved 98.7% on-time delivery rates for orders exceeding 10,000 units. Our CNC systems' flexibility allowed seamless switching between different product types - from electrical insulation cardboard to laminated wood components - with less than 15 minutes changeover time.

Global Applications and Customization

As a leading transformer insulation parts processing equipment manufacturer in China, our solutions have been successfully implemented across multiple regions:

- Southeast Asia: Customized for high-humidity environment operation

- South America: Modified for 60Hz power system requirements

- Russia: Cold-weather package for -40°C operation

- India/Pakistan: Dust-proof configurations

Our OEM service for transformer insulation parts processing equipment includes complete documentation packages with:

- 3D CAD models of all components

- Material certifications (UL, IEC, IEEE compliant)

- Multi-language operation manuals

- Remote monitoring integration options

Conclusion and Next Steps

This case study demonstrates how Gaomi Hongxiang's CNC transformer insulation parts processing equipment delivers:

- Precision manufacturing for electrical insulation components

- Scalable solutions for bulk order production

- Customized EVA molding and laminated wood processing

- Global compliance and regional adaptation

Ready to transform your transformer insulation parts manufacturing? Contact our engineering team today to discuss your specific requirements for CNC transformer insulation parts processing equipment. We offer comprehensive solutions from initial design to after-sales support, ensuring your production meets the highest industry standards.

As a trusted transformer insulation parts processing equipment sourcing partner, we provide complete technical documentation, factory acceptance testing, and operator training packages with every system.

NAVIGATION

MESSAGE

Request A Quote?