0000-00

Market Overview: Transformer Equipment Demand in 2023

The global transformer market is projected to grow at 6.8% CAGR through 2027, driven by renewable energy integration and grid modernization projects. However, supply chain disruptions have created unprecedented challenges for transformer core for heavy machinery procurement. Key pain points include:

- Extended lead times (up to 52 weeks for some power transformers)

- Critical material shortages (electrical steel, insulating materials)

- Logistics bottlenecks at major ports

- Quality inconsistencies from alternative suppliers

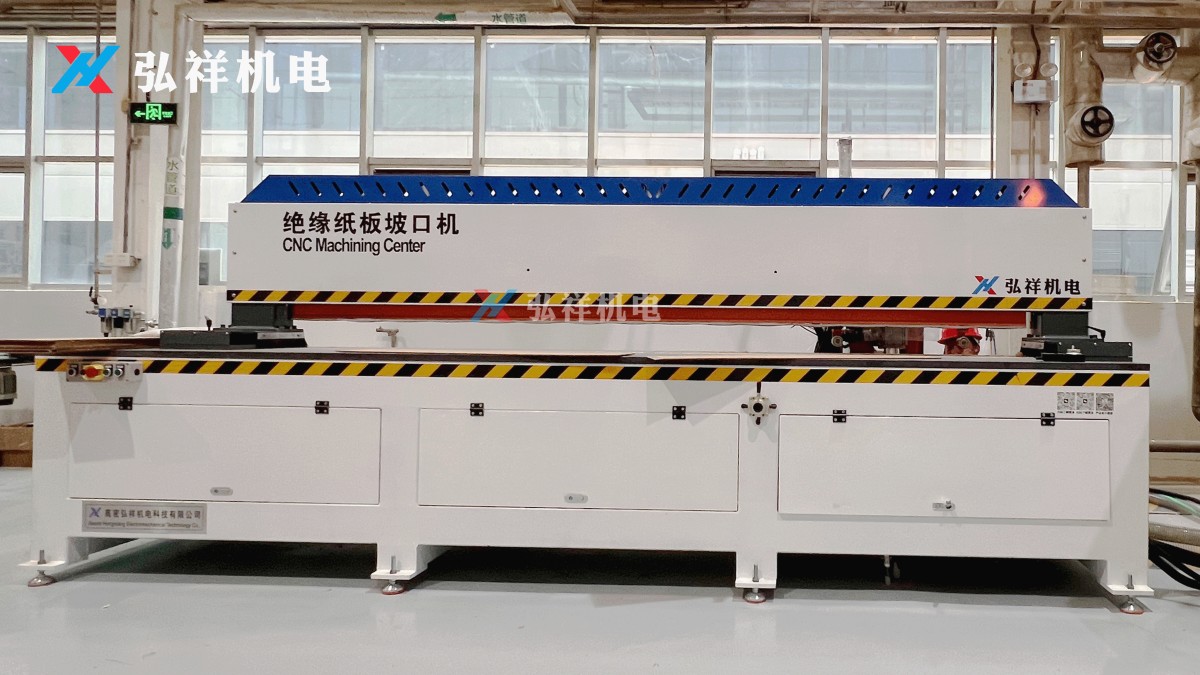

Our Automatic four-sided chamfering machine demonstrates how precision engineering can mitigate these risks through standardized production processes.

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board.

Technical Performance: Ensuring Reliability in Transformer Components

Transformer insulation parts processing equipment must meet stringent IEC 60076 standards while accommodating:

Procurement Guide: Selecting Transformer Core Suppliers

When evaluating Transformer insulation parts processing equipment manufacturers in China, consider these critical factors:

- Vertical Integration: Look for suppliers controlling raw material sourcing (electrical insulating cardboard production capabilities)

- Certifications: ISO 9001, ISO 14001, and specific transformer component certifications

- Lead Time Flexibility: Dual-source manufacturing strategies like ours in Shandong and Vietnam facilities

- Testing Capabilities: In-house partial discharge testing and thermal aging tests

Why Choose Gaomi Hongxiang Electromechanical Technology

With 15 years specializing in transformer core for heavy machinery, we offer:

- Custom transformer insulation parts processing equipment designed for your specific voltage class (up to 500kV)

- AI-assisted quality control systems reducing defects by 72% versus industry average

- Dedicated account managers fluent in English, Russian, and Spanish

- Just-in-time inventory programs with 98.6% on-time delivery record

Contact our engineering team today to discuss your transformer supply chain requirements and discover how our Automatic four-sided chamfering machine can enhance your production reliability.

NAVIGATION

MESSAGE

Request A Quote?