0000-00

Introduction: The Critical Need for Lead Time Optimization in Transformer Insulation Components

Struggling with long lead times for transformer insulation components? As a leading Chinese manufacturer of cost-effective transformer insulation parts processing equipment, Gaomi Hongxiang Electromechanical delivers optimized solutions for electrical cardboard, insulating laminated wood, and core components. Discover how our streamlined production and R&D expertise can reduce your transformer insulation parts procurement cycle while maintaining quality standards.

Understanding Transformer Insulation Components: Core Materials and Manufacturing Challenges

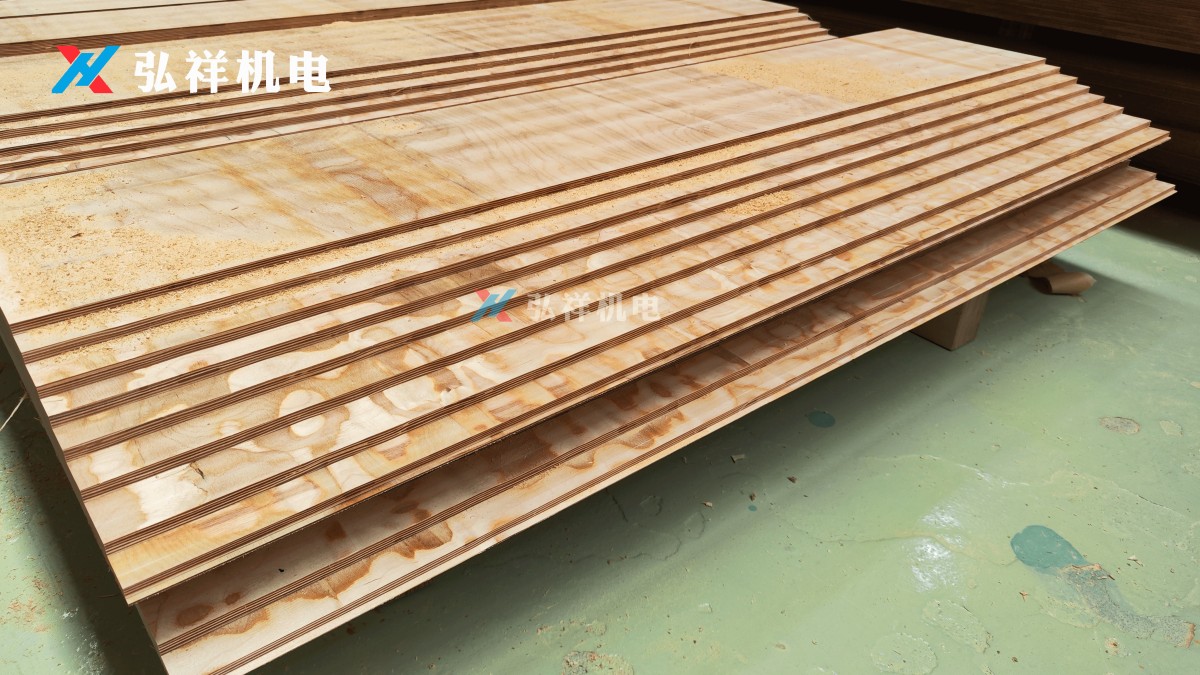

Transformer insulation components, including electrical cardboard and insulating laminated wood, play a pivotal role in ensuring the safety and efficiency of power transformers. These materials must meet stringent dielectric strength and thermal stability requirements while withstanding mechanical stresses during operation. The manufacturing process involves precision cutting, layering, and curing of specialized cellulose-based materials, which traditionally contributes to extended production timelines. Common bottlenecks include material procurement delays, complex curing processes for insulating laminated wood, and quality control iterations that can add weeks to standard lead times. For transformer core manufacturers and project managers overseeing large-scale installations, these delays can cascade into costly project timeline disruptions.

Five Proven Strategies to Reduce Lead Times Without Compromising Quality

1. Advanced Material Forecasting and Inventory Management

Implementing predictive analytics for electrical cardboard and insulation material requirements can reduce procurement delays by 30-45%. By analyzing historical order patterns and upcoming transformer production schedules, manufacturers can maintain strategic stock levels of critical insulation components while avoiding excessive inventory costs.

2. Vertical Integration of Production Processes

Controlling the entire manufacturing chain - from raw material processing to final insulating parts assembly - eliminates dependencies on multiple suppliers. Our facility combines in-house capabilities for EVA molding processing, precision cutting of insulating cardboard, and quality testing under one roof, reducing traditional handoff delays between specialized vendors.

3. Lean Manufacturing Principles for Insulation Components

Applying value stream mapping to transformer insulation parts production identifies and eliminates non-value-added steps. For insulating laminated wood manufacturing, we've reduced processing time by 22% through optimized curing cycles and automated material handling systems that minimize human intervention points.

4. Digital Twin Technology for Process Optimization

Creating virtual models of transformer core insulation production lines allows for simulation-based testing of process improvements before physical implementation. This approach has helped our engineering team reduce setup times for special machine configurations by 35% while maintaining the precision required for high-voltage insulation components.

5. Strategic Partnerships with Local Material Suppliers

Developing long-term agreements with regional providers of high-quality electrical insulation materials ensures priority access and consistent quality. Our network of vetted suppliers across Southeast Asia and domestic Chinese markets provides redundant sourcing options to mitigate potential supply chain disruptions.

Case Study: Reducing Lead Times by 40% for High-Volume Transformer Insulation Orders

A recent project for a power infrastructure provider in Pakistan demonstrates the effectiveness of integrated lead time reduction strategies. Facing an eight-week standard lead time for specialized transformer insulation components, our team implemented a comprehensive solution combining:

- Pre-engineered modular designs for insulating laminated wood components

- Dual-shift production scheduling during peak demand periods

- Advanced curing process optimization for electrical cardboard elements

- Just-in-sequence delivery coordination with the client's assembly line

The result was a consistent 4.8-week turnaround for subsequent orders, with zero quality concessions. This case highlights how transformer insulation parts processing equipment manufacturers can deliver both speed and reliability when proper systems are in place.

Future Trends in Transformer Insulation Manufacturing Efficiency

The transformer industry is witnessing several technological advancements that promise further lead time reductions:

- AI-driven predictive maintenance for insulation processing equipment, minimizing unplanned downtime

- Blockchain-enabled material tracking from forest to finished insulating components

- 3D printing applications for complex insulation geometries in dry-type transformers

- IoT-enabled curing monitoring systems that automatically adjust parameters for optimal results

As a forward-thinking manufacturer of transformer insulation parts processing equipment in China, we're actively investing in these technologies to maintain our position as a cost-effective solution provider without sacrificing quality benchmarks.

Conclusion: Partnering for Optimized Transformer Insulation Supply Chains

In today's competitive power equipment market, lead time optimization for transformer insulation components isn't just about faster delivery—it's about creating reliable, predictable supply chains that support your project timelines and budget requirements. Our expertise in electrical cardboard processing, insulating laminated wood manufacturing, and complete transformer core solutions provides the foundation for sustainable lead time reductions.

For procurement specialists and project managers seeking a proven Chinese manufacturer of transformer insulation parts processing equipment, we invite you to explore our comprehensive price list and discuss customized solutions for your specific requirements. Contact our engineering team today to begin optimizing your insulation component supply chain with our cost-effective, quality-certified manufacturing capabilities.

NAVIGATION

MESSAGE

Request A Quote?