0000-00

Market Overview: China's Transformer Core Manufacturing Landscape

China has emerged as a global leader in transformer core production, with manufacturers specializing in high-performance solutions for heavy machinery. The market is characterized by advanced processing technologies, stringent quality control measures, and competitive pricing structures. Leading manufacturers like Gaomi Hongxiang Electromechanical Technology Co., Ltd. have established themselves as reliable partners for global clients, offering comprehensive services from R&D to after-sales support. The industry has seen significant growth in recent years, particularly in the development of custom transformer insulation parts processing equipment that meets international standards.

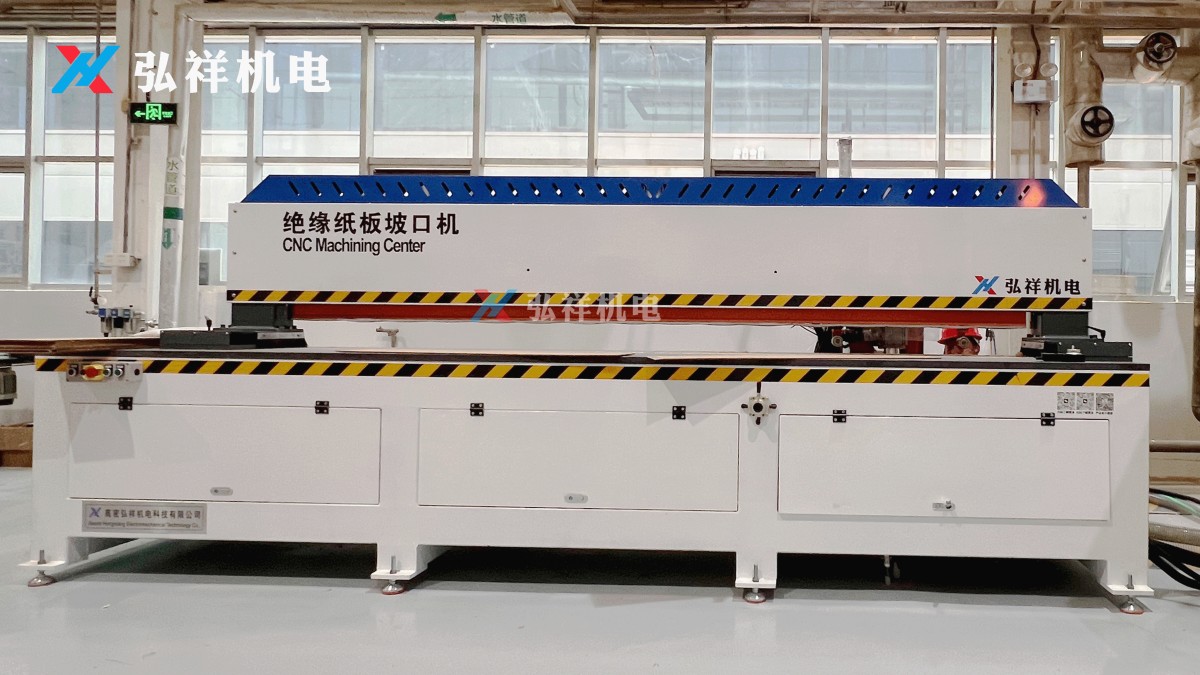

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board.

Technical Performance Comparison

When comparing transformer core manufacturers, several technical parameters stand out as critical differentiators:

- Core Loss Performance: Top manufacturers achieve core loss values below 1.0 W/kg at 1.7T/50Hz

- Dimensional Accuracy: Precision cutting equipment maintains tolerances within ±0.05mm

- Material Quality: High-grade silicon steel with consistent magnetic properties

- Insulation Systems: Custom transformer insulation parts processing equipment ensures uniform dielectric strength

- Thermal Stability: Designs that maintain performance across wide temperature ranges

Procurement Guide for Transformer Cores

Selecting the right transformer core manufacturer requires careful consideration of multiple factors. For heavy machinery applications, the transformer core must withstand vibration and mechanical stress while maintaining electrical performance. Key considerations include:

- Manufacturer's experience with similar applications

- Availability of custom design services

- Quality certifications (ISO, IEC, etc.)

- Production capacity and lead times

- After-sales support and technical assistance

For precision machining needs, consider complementary equipment like the Automatic four-sided chamfering machine which can enhance production efficiency for transformer components.

Why Choose Gaomi Hongxiang Electromechanical Technology

As a leading transformer core manufacturer in China, we offer distinct advantages for global clients:

- Integrated R&D and manufacturing capabilities

- Specialization in transformer insulation parts processing equipment

- Strict compliance with international standards (IEC 60076, IEEE C57.12.00)

- Comprehensive after-sales service network

- Proven track record in heavy machinery applications

Our expertise in custom transformer solutions ensures optimal performance for your specific application requirements. Contact our team today to discuss your project needs and receive a tailored proposal.

NAVIGATION

MESSAGE

Request A Quote?