0000-00

Selected from "Insulating Materials"

On November 9, the 800 kV/80 kA high-capacity circuit breaker, jointly developed by State Grid Shaanxi Electric Power Co., Ltd., Henan Pinggao Electric Co., Ltd., Xi 'an Jiaotong University, China Electric Power Research Institute, and China Electric Equipment Group Science and Technology Research Institute Co., Ltd., successfully passed the new product technical appraisal organized by the China Society for Electrical Engineering in Beijing. The appraisal committee unanimously concluded that "the comprehensive performance indicators of the product have reached the international leading level, and agreed to pass the new product technical appraisal." This marks the successful development of the world's first 800 kV/80 kA high-capacity circuit breaker.

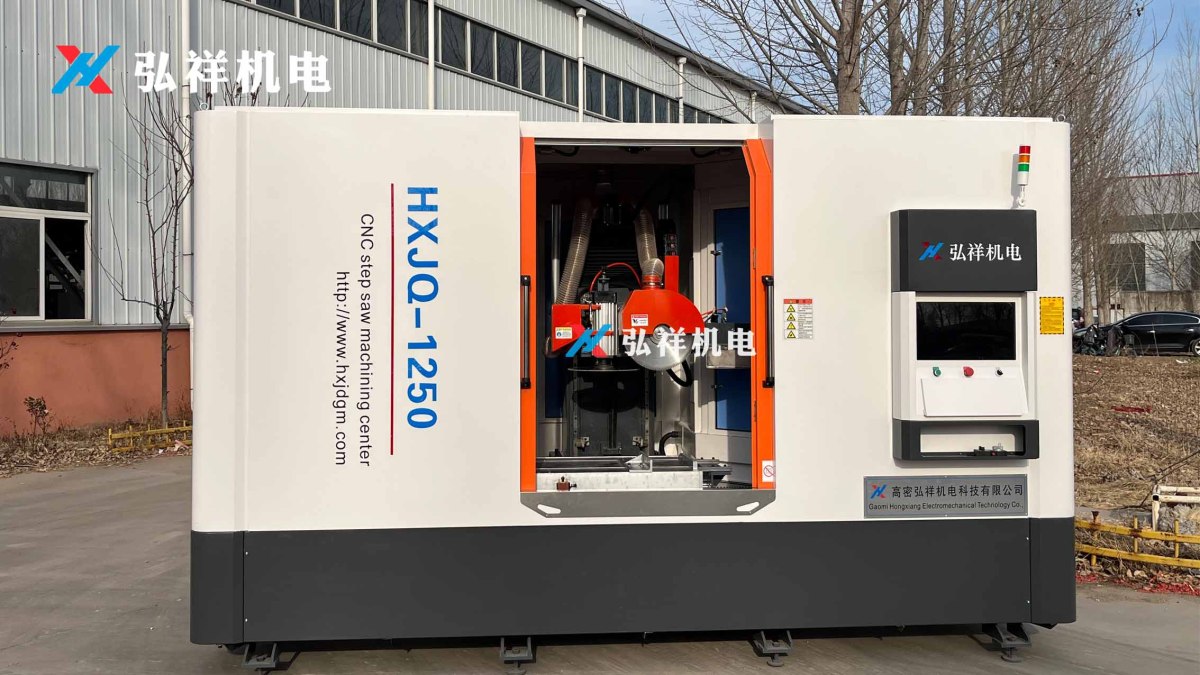

The Hongxiang CNC step saw is designed for the processing of laminated wood step blocks and guide frames with adhesive structures. The machining process is digitally controlled to meet the quality standards of step blocks. This equipment features simple CNC operation, eliminating the need for professionals to write complex programming such as G-code. Users can directly input the sawing parameters, making it a domestically innovative and user-friendly solution.

The frame is strictly treated by two times of aging, which eliminates the internal deformation stress of the parts to the maximum extent, improves the stability of the parts effectively, and avoids deformation, so that the machine tool has the extremely high dynamic precision, static precision and stability.

As a key solution to the 750 kV grid short-circuit current exceeding standards in Northwest China, this breakthrough has significantly advanced China's high-voltage, high-capacity disconnection technology.

In recent years, the rapid expansion of the 750 kV main grid in Northwest China, coupled with large-scale renewable energy integration and breakthrough developments in ultra-high voltage power transmission, has increasingly exposed issues with short-circuit current exceeding safety limits in 750 kV systems. Addressing these challenges, State Grid Shaanxi Electric Power Co., Ltd. has partnered with the State Grid Shaanxi Electric Power Research Institute to initiate the 2024 National Grid Corporation of China Science and Technology Project titled "Key Technologies and Equipment Development for 800 kV/80 kA AC SF6 Circuit Breaker Short-Circuit Current Interrupting". The project is now advancing its R&D efforts to enhance grid reliability.

In order to save material and reduce product cost, the system development combines with the user's use and applies three kinds of processing methods, square material processing, oblique material processing and L-shaped material processing. In order to improve processing efficiency, the system development combines with the actual processing operation and divides into reciprocating processing and single item processing.

Processing of laminated wood stair treads for transformers, featuring one-click startup and simple operation. Equipped with professional imported cemented carbide saw blades for extended service life. The saw-cut surface is smooth, eliminating the need for secondary processing or manual grinding, without damaging the treads, and free from carbonization or burn-off. Based on the Bao Yuan system from Taiwan as the foundation, a dedicated CNC control system for specialized machinery has been independently developed.

"During the development of the 800 kV/80 kA circuit breaker, we encountered multiple technical challenges. For instance, the short-circuit current energy will increase by 60%, the recovery voltage rise rate in critical tests will rise by 27%, and the ablation resistance of core components requires significant enhancement—all of which impose higher demands on the product's mechanical performance," said Yang Dingge, Chief Grid Maintenance Expert at State Grid Shaanxi Electric Power Company.

To tackle the challenges, the project team collaborated to conduct theoretical research and simulation tests on electrical arcs. They innovatively developed a high-precision simulation model for the full opening process of 800 kV circuit breakers and established an internationally advanced arc measurement system, enabling precise understanding of arc characteristics under high-voltage and high-current conditions. This led to the successful development of the world's first 800 kV/80 kA double-break arc extinguishing chamber. Additionally, they pioneered the use of ablation-resistant graphene contact materials, meeting the 20-cycle electrical life requirement for 800 kV/80 kA circuit breakers and resolving the challenge of withstanding 80 kA arc ablation in critical components. The team also conducted research on mechanical characteristic matching and buffer structure optimization for operating mechanisms, overcoming technical barriers in the coordinated optimization of high-capacity opening and operating characteristics, thereby enhancing the transmission system.

Human-machine separation ensures safety and reliability. After inputting the processing parameters, the entire machining process requires no operator intervention. Material removal device: Sawed wood strips can be promptly cleared to prevent debris scattering caused by material collapse during saw blade passage.

The device employs dedicated CNC macro programs for foolproof operation, delivering high-precision machining with strict ±0.10mm repeatability control. Its efficiency surpasses conventional machining centers by over threefold, overcoming the tool-holding capacity limitations of traditional systems. The intuitive interface requires only drawing input of parameters, eliminating the need for technical personnel to handle complex tasks like drafting or programming. Even novice operators can master the system within half a day.

"After 23 months of development, the 800 kV/80 kA circuit breaker has been successfully developed. The new product's performance parameters are internationally leading and fully compatible with existing equipment dimensions, enabling direct replacement and upgrade. This will significantly enhance the efficiency and cost-effectiveness of power grid capacity expansion and transformation," said Sheng Yong, Chief Expert of State Grid Shaanxi Electric Power Co., Ltd. Upon commissioning, the circuit breaker will further improve the Northwest Power Grid's ability to handle extreme short-circuit currents, support the safe and stable operation of energy cluster transmission grids, and provide robust equipment support for the secure and stable operation of China's main power grid.

GaoMi HongXiang Electromechanical Technology Co., Ltd. is a private enterprise specializing in global customer services. The company provides three core product lines: power transformer assembly manufacturing, electrical insulation paperboard, insulation laminated wood, and insulation component processing, supported by AI-driven specialized machinery. As a comprehensive provider, it integrates R&D design, production, sales, installation, training, and after-sales services. Its products are widely sold domestically and exported to Southeast Asia, South America, India, Pakistan, Russia, and other regions.

NAVIGATION

MESSAGE

Request A Quote?