0000-00

Excerpt from “Transformer Information”

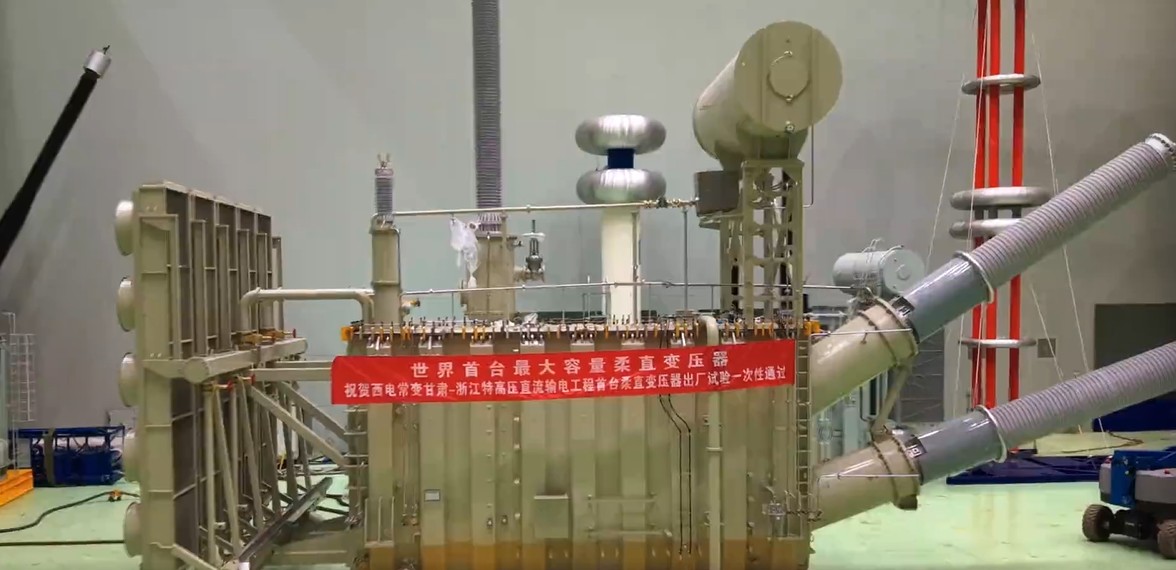

Recently, China XD Electric Changbian, a subsidiary of China XD Electric, successfully developed a 750 MVA flexible DC transformer, setting a global record for the highest capacity of a single converter transformer in the field of flexible DC transmission. The company overcame key technical challenges such as optimizing large-capacity magnetic leakage, collaborative design of composite insulation and temperature rise, and research on adaptability to special operating conditions, marking a significant breakthrough in China's independent R&D of core equipment for ultra-high voltage flexible DC.

This product represents the world's first application of a single 750 MVA high-capacity transformer, entirely independently designed by XDCEC. It is a UHV flexible DC transformer developed for the Gansu-Zhejiang ±800 kV UHVDC transmission project (Gan-Zhe Project), a key national West-East Power Transmission initiative, providing core equipment support for the receiving-end Yuezhou Converter Station.

The Gan-Zhe Project, the world's first initiative to deploy self-developed ±800 kV, 8 GW ultra-high voltage (UHV) full-capacity flexible DC technology, effectively addresses challenges including unstable high-proportion renewable energy generation at the sending end and complex dynamic responses in receiving-end systems with high external power consumption. This breakthrough significantly enhances the stability and operational flexibility of large-scale power grids. Spanning six provinces (autonomous regions) with a total length of 2,370 kilometers, the project will deliver over 36 billion kWh of clean electricity annually to Zhejiang upon commissioning. It plays a pivotal role in optimizing energy structures and achieving the "dual carbon" goals, while holding profound implications for building a new energy system and safeguarding national energy security.

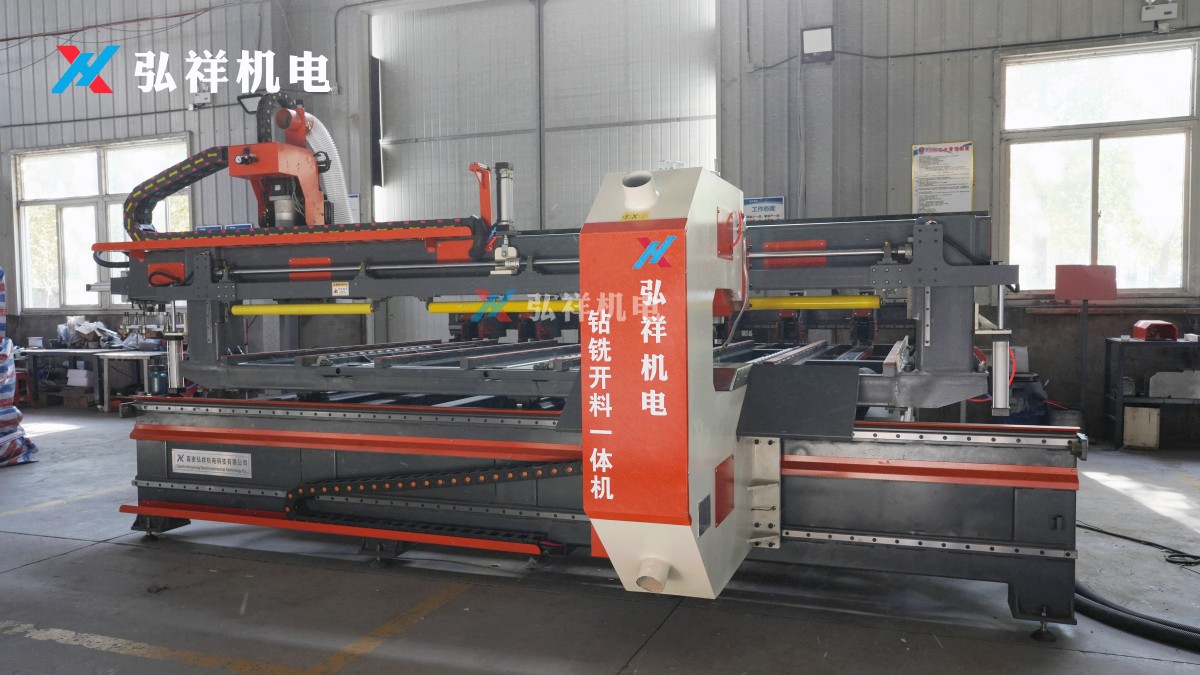

Drilling, Milling and Profiling Machine

This machine is a modern, intelligent processing system that integrates three core capabilities:high-precision drilling, complex milling, and profile cutting.

In the Gansu-Zhejiang power grid construction project, XDCC (Xi 'an Electric Power Corporation Chang' an Branch) upheld the ultra-high voltage spirit of "daring to take responsibility, pursuing excellence, serving customers, and striving for excellence." The company developed seven ZRDFP-750000/500-400 flexible DC transformers for the Yuezhou Converter Station. To ensure high-quality project execution, XDCC established a dedicated task force led by the top executive, coordinating resources to implement meticulous control over the entire process—from design and procurement to production and testing—fully meeting the project's construction requirements.

Innovation drives breakthroughs in overcoming technical challenges

During the R&D design phase, the technical team conducted systematic simulation calculations and model tests to validate critical operational conditions for large-capacity flexible DC transformers, including DC magnetic bias tolerance, high-frequency harmonic response, and no-load capacity endurance. To address the challenges of magnetic flux leakage control and temperature management caused by significantly increased capacity, the team innovatively adopted advanced technologies such as fully quantized magnetic flux leakage control strategies, iterative oil flow distribution calculations, and multi-point fiber-optic temperature measurement. Through comprehensive digital simulation and validation, potential risks were identified and mitigated in advance, ensuring the design's reliability and long-term stability under extreme operating conditions.

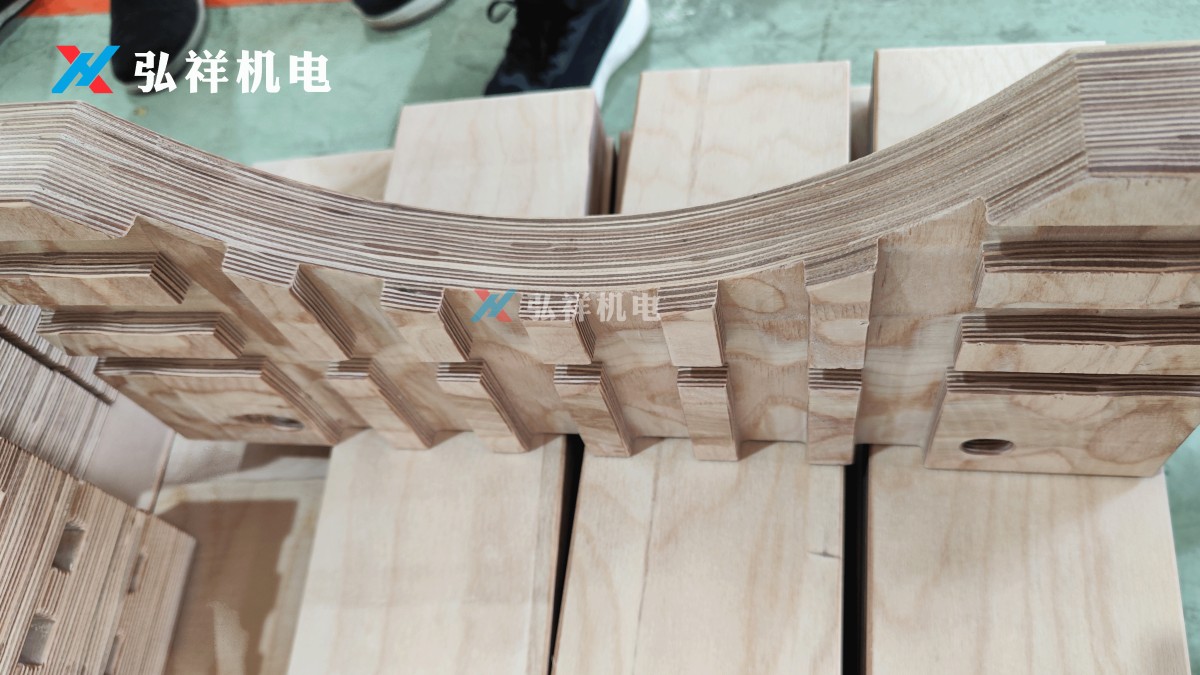

Lean Manufacturing Strictly Control Quality Details

To address the specialized requirements of large-capacity flexible DC transformers in manufacturing, XDCC has independently developed specialized tooling for critical processes including coil winding and core assembly, ensuring core component quality at the source. The company also implements end-to-end quality enhancement controls, with particular emphasis on key control points such as parallel current-carrying conductor assembly, foreign particle protection, and oil treatment processes. This ensures every product meets the highest quality standards and withstands the most rigorous testing.

Rigorous testing validates product performance

In the test stage, the product has passed dozens of rigorous tests including lightning shock, operation shock, AC/DC withstand voltage, polarity reversal, etc. All test data meet the standard at the first time, and the temperature rise and loss measurement results are better than the design value, which fully verifies the advanced design and reliable manufacture.

GaoMi HongXiang Electromechanical Technology Co., Ltd. is a private enterprise specializing in global customer services. The company provides three core product lines: power transformer assembly manufacturing, electrical insulation paperboard, insulation laminated wood, and insulation component processing, supported by AI-driven specialized machinery. As a comprehensive provider, it integrates R&D design, production, sales, installation, training, and after-sales services. Its products are widely sold domestically and exported to Southeast Asia, South America, India, Pakistan, Russia, and other regions.

NAVIGATION

MESSAGE

Request A Quote?