0000-00

Selecting the right grade of insulating cardboard is critical for transformer performance and longevity. This comparative analysis examines key electrical insulation materials for transformer cores, evaluating durability, thermal resistance, and cost-effectiveness. As a leading Chinese manufacturer of transformer insulation components, we provide expert insights to help technical evaluators, procurement teams, and project managers make informed decisions about electrical cardboard specifications for optimal transformer operation and safety.

Key Properties of Transformer Insulating Cardboard

When evaluating insulating cardboard for transformer applications, several critical properties must be considered. The dielectric strength determines the material's ability to withstand electrical stress without breakdown, typically measured in kV/mm. Thermal class ratings indicate the maximum continuous operating temperature the material can endure, ranging from Class A (105°C) to Class H (180°C). Mechanical properties including tensile strength (measured in N/mm²) and density (g/cm³) affect durability during transformer assembly and operation. Moisture resistance is particularly important as water absorption can significantly degrade insulation performance. The comparative tracking index (CTI) measures resistance to surface electrical tracking, while the partial discharge inception voltage (PDIV) indicates performance under high voltage stress. These properties vary significantly across different grades of electrical cardboard, making material selection crucial for specific transformer designs and operating environments.

Comparative Analysis of Common Insulating Cardboard Grades

The transformer industry typically utilizes three primary grades of insulating cardboard, each with distinct characteristics. Grade A (Standard) offers basic insulation with dielectric strength of 12-15 kV/mm and thermal resistance up to 105°C, suitable for small distribution transformers. Grade B (Premium) provides enhanced performance with 18-22 kV/mm dielectric strength and 130°C thermal rating, commonly used in medium-power applications. Grade C (High-Performance) delivers superior characteristics including 25-30 kV/mm dielectric strength, 155°C thermal capability, and excellent mechanical stability, making it ideal for large power transformers and harsh environments. Premium grades often incorporate special cellulose treatments or synthetic reinforcements to improve moisture resistance and dimensional stability. While higher grades command 20-40% price premiums, they can extend transformer lifespan by 30-50% in demanding applications, offering better long-term value for critical installations.

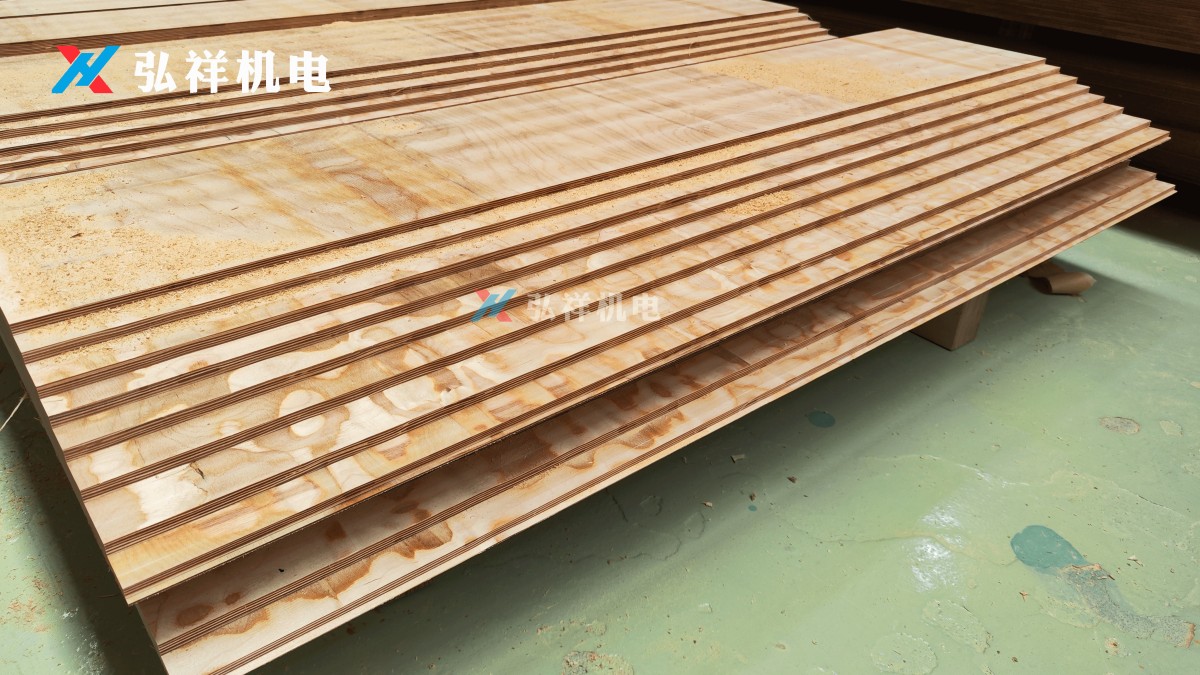

Material Composition and Manufacturing Processes

The performance differences between insulating cardboard grades stem from their material composition and manufacturing processes. Standard grades typically use pure cellulose fibers with basic pressing and drying techniques. Premium variants incorporate refined wood pulp with controlled fiber orientation and additional calendering for improved density. High-performance grades may include synthetic additives like aramid fibers or special resin impregnation for enhanced thermal and mechanical properties. Advanced manufacturing techniques such as multi-stage hot pressing and controlled humidity curing contribute to the superior characteristics of top-tier materials. These processes affect not just initial properties but also long-term aging characteristics, with premium grades demonstrating better resistance to thermal degradation and mechanical fatigue over decades of service.

Cost-Benefit Analysis for Different Applications

Selecting the optimal insulating cardboard requires careful cost-benefit analysis based on application requirements. For small distribution transformers with moderate operating temperatures (below 90°C), Grade A materials provide adequate performance at the lowest cost. Industrial and commercial transformers experiencing frequent load variations benefit from Grade B's improved thermal cycling resistance. Critical applications like utility-scale power transformers, offshore installations, or tropical environments justify Grade C's premium pricing through reduced failure rates and extended maintenance intervals. The total cost of ownership calculation should consider not just material costs but also installation complexity, expected lifespan, and potential downtime expenses. In many cases, upgrading one grade level can yield 20-30% longer service life with only 10-15% higher initial material cost, representing excellent value for money in medium to large transformers.

Industry Standards and Compliance Considerations

Transformer insulating cardboard must comply with various international standards that define performance requirements. IEC 60641 establishes specifications for pressboard and presspaper used in electrical equipment, while IEEE C57.12.00 covers general requirements for liquid-immersed transformers. NEMA MW1000 provides guidelines for moisture-resistant materials, particularly important for outdoor installations. Regional variations exist, with European EN standards, Chinese GB standards, and North American ANSI/IEEE requirements sometimes specifying different test methods or acceptance criteria. Premium grade materials often exceed minimum standard requirements, offering additional safety margins that prove valuable in abnormal operating conditions. Compliance documentation should include type test reports, material certifications, and factory test data to demonstrate conformance with project specifications and regulatory requirements.

Selection Guidelines for Different Transformer Types

The optimal insulating cardboard selection varies significantly across different transformer types and operating conditions. For dry-type transformers, materials with superior thermal conductivity and flame retardancy are prioritized, often requiring special resin treatments. Oil-immersed transformers benefit from grades with excellent oil compatibility and low moisture absorption. Compact or high-power density designs demand materials with exceptional mechanical strength to withstand electromagnetic forces. Harsh environments (high humidity, pollution, or seismic zones) necessitate premium grades with enhanced environmental resistance. Special applications like traction transformers for railways or furnace transformers for industrial heating require customized solutions balancing multiple performance parameters. Our technical team can provide application-specific recommendations considering voltage class, cooling method, load profile, and environmental factors to optimize both performance and cost-effectiveness.

Conclusion and Expert Recommendations

The selection of transformer insulating cardboard represents a critical balance between technical requirements and economic considerations. While standard grades suffice for basic applications, investing in premium materials often yields substantial long-term benefits through improved reliability and extended service life. For most industrial and utility applications, we recommend specifying Grade B as the baseline, reserving Grade C for critical installations or challenging environments. Proper material handling and storage procedures are equally important to preserve insulation properties before installation. As a leading manufacturer of transformer insulation components with ISO 9001 certification and 15 years of industry experience, we offer comprehensive technical support to help clients select and implement the optimal insulation solutions for their specific requirements.

Contact Our Technical Team Today

For detailed specifications, custom material solutions, or assistance with your transformer insulation requirements, contact our engineering specialists. We provide complete technical documentation, samples for evaluation, and competitive pricing for all grades of electrical insulating cardboard.

Request a consultation or quote to discuss how our high-performance transformer insulation components can enhance your equipment reliability and operational efficiency.

NAVIGATION

MESSAGE

Request A Quote?