0000-00

Selected from "Insulating Materials"

Research Background and Innovations

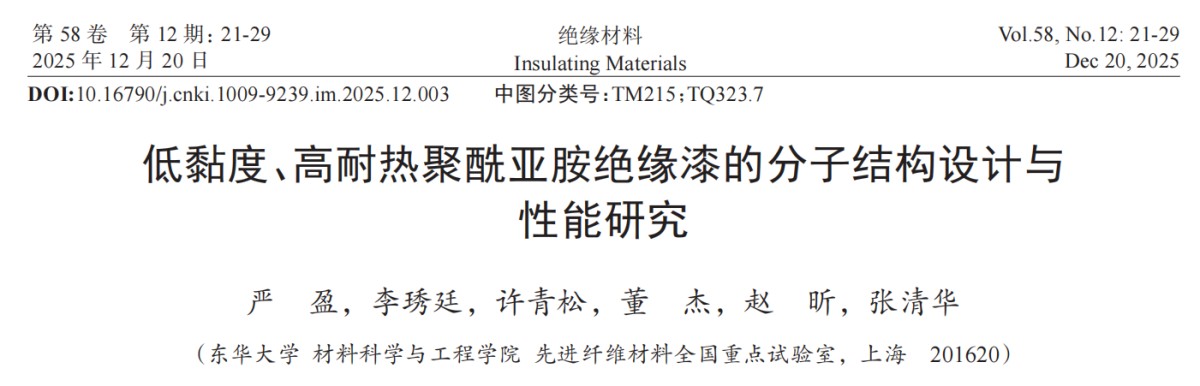

The rapid development of the new energy vehicle industry has raised higher requirements for insulation materials in drive motors, demanding stable performance under high-temperature and high-load conditions. Polyimide (PI), recognized as the highest-temperature-resistant insulating paint material, is widely used due to its excellent properties. However, the precursor polyamide acid solution in traditional PI insulating paints still exhibits high viscosity at low solid content, hindering uniform multi-layer coating. Our team innovatively proposed a "latent" intermediate strategy: preparing a carboxylic amine salt end-curing agent through the neutralization reaction of butyric acid and aromatic amines, which is then introduced into the anhydride-terminated PMDA-ODA oligomer. During high-temperature curing, the intermediate decomposes to release amine groups, which continue to react to form high-molecular-weight PI, thereby balancing low-viscosity processing with high-performance paint film requirements.

Figure 1 Schematic diagram of PI insulating paint preparation route

Core Methodology: Molecular Design and Preparation Process

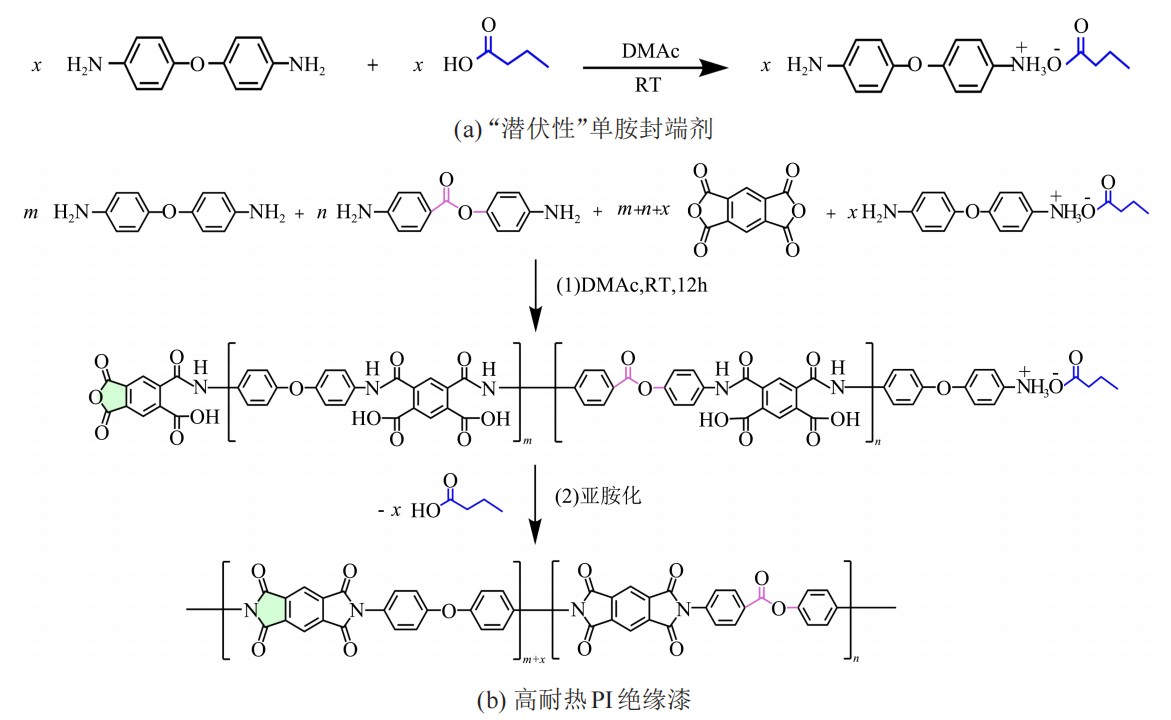

By adjusting the monomer ratios (ODA, APAB, BA, PMDA), a series of PI coatings (e.g., PI-P-0 to PI-P-4) were synthesized. The incorporation of a "latent" intermediate significantly reduced the viscosity of the paint solution—when the BA content was 5%, the viscosity decreased from 1712 mPa·s to 835 mPa·s (at 20°C), thereby enhancing coating efficiency.

The intermediate was decomposed at 180~200℃ and the PI was formed at 300℃. The thermal stability of the PI was similar to that of the conventional PI.

Figure 2 Relationship between Apparent Viscosity of PI Insulation Paint and BA Content

Hongxiang mechanical shears are essential equipment for enhancing the efficiency and quality of electrical material processing. They enable precise and efficient material cutting to meet the electrical industry's requirements for dimensional accuracy and safety performance. The cutting edges are smooth and free of burrs, ensuring the insulation properties of electrical equipment. Batch cutting is completed rapidly, significantly improving production efficiency.

Performance Breakthrough: Comprehensive Optimization of Thermal, Mechanical, and Electrical Properties

1.Significant improvement in heat resistance

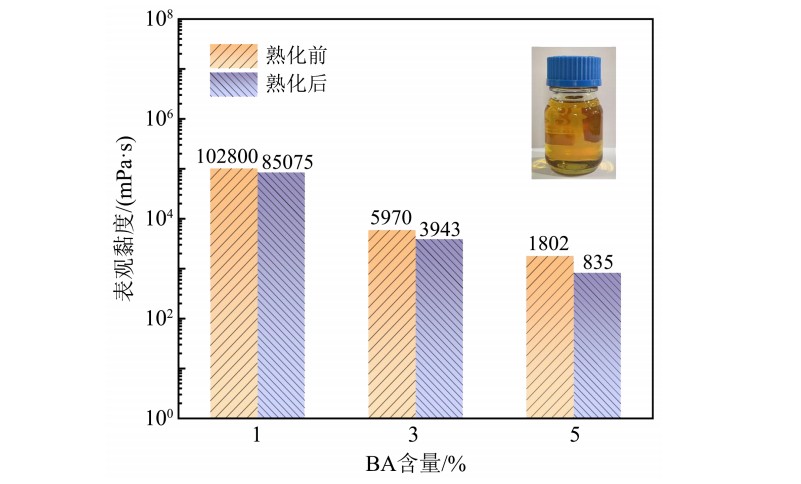

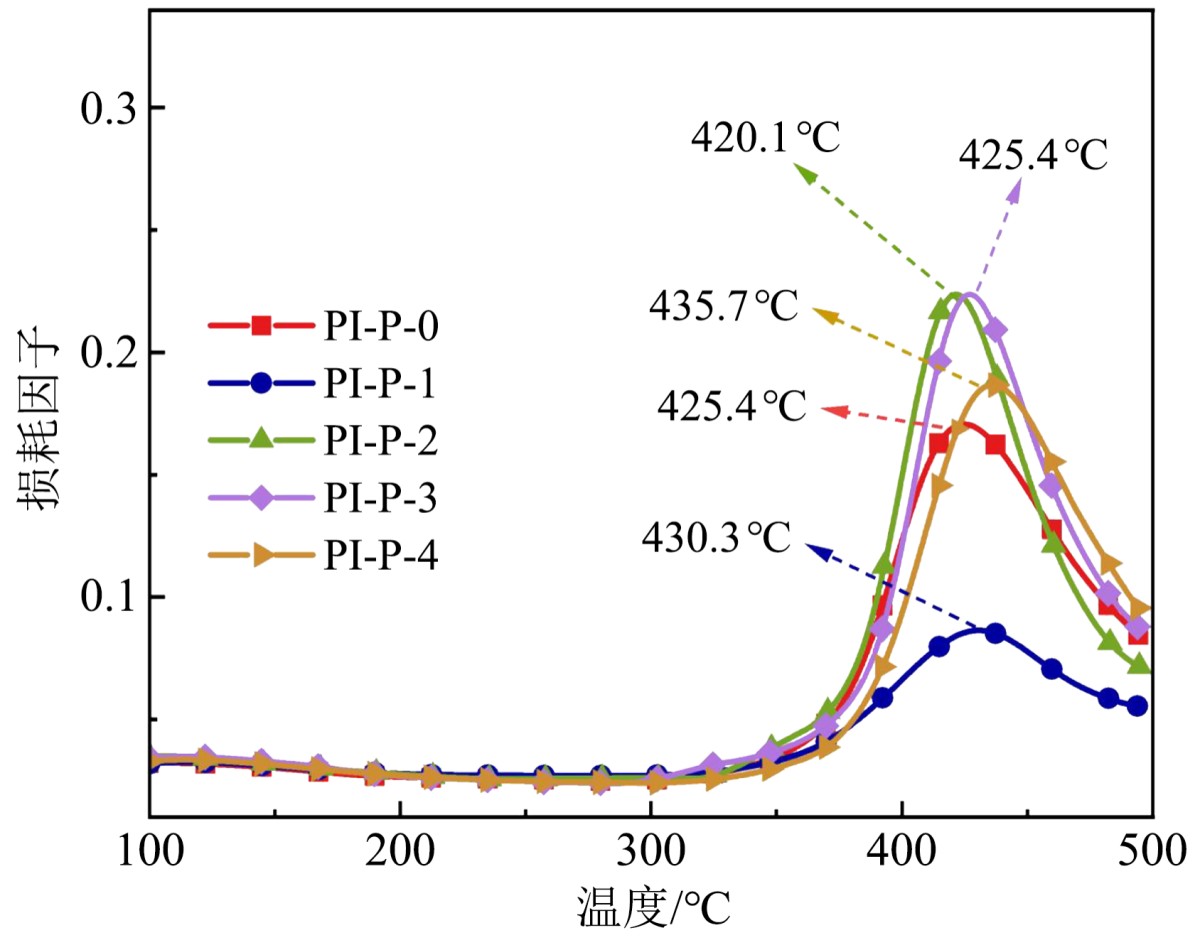

By incorporating the rigid monomer APAB and increasing the heat treatment temperature, the glass transition temperature (Tg) of the film exceeded 420°C. Differential mechanical analysis (DMA) revealed that at 40% APAB content, Tg reached 429.3°C. After 450°C heat treatment, the Tg of PI-P-1 further increased to 430.3°C, representing a 5.23% improvement compared to the 350°C treatment. XPS analysis indicated that high temperatures promoted molecular chain cross-linking, thereby enhancing thermal stability.

(a) Cyclization at 350°C

(b) Cyclization at 450°C

Figure 3 DMA curves of high-temperature-resistant PI film prepared at different temperatures

2.Excellent mechanical properties:

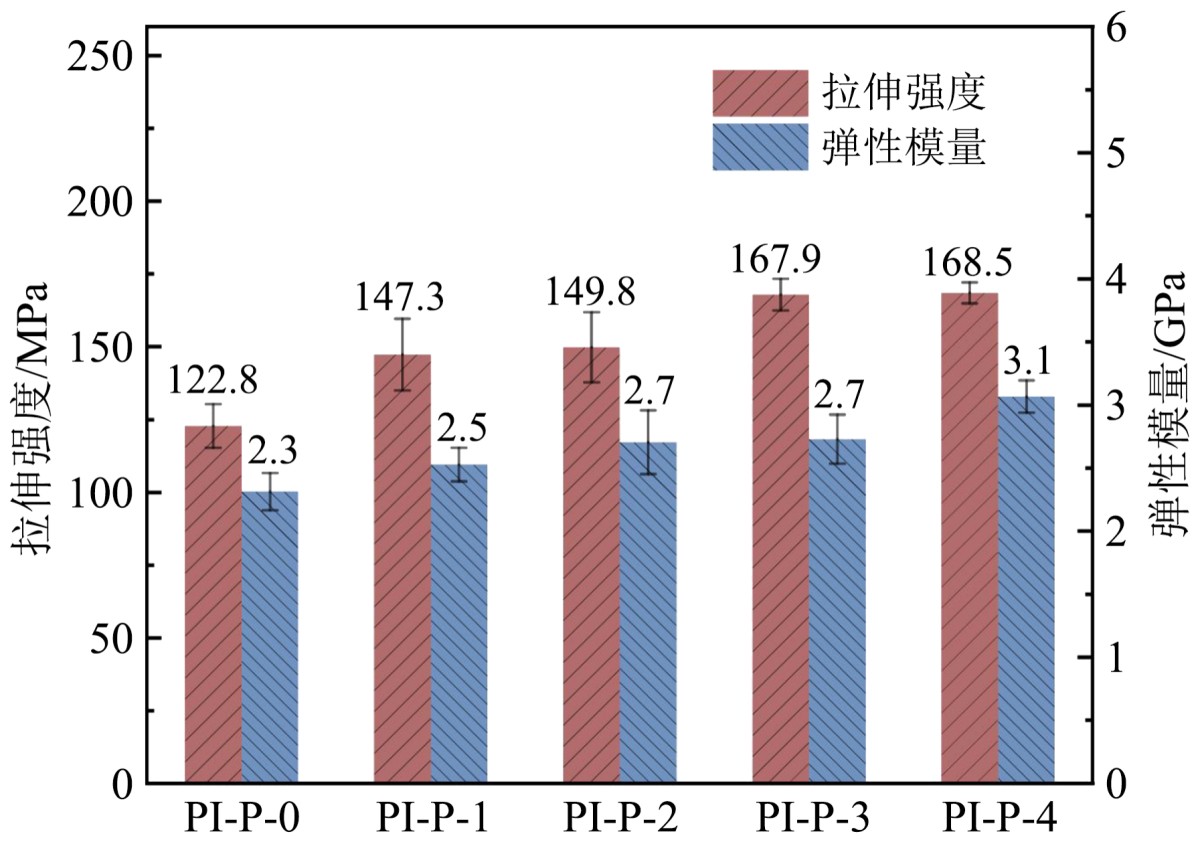

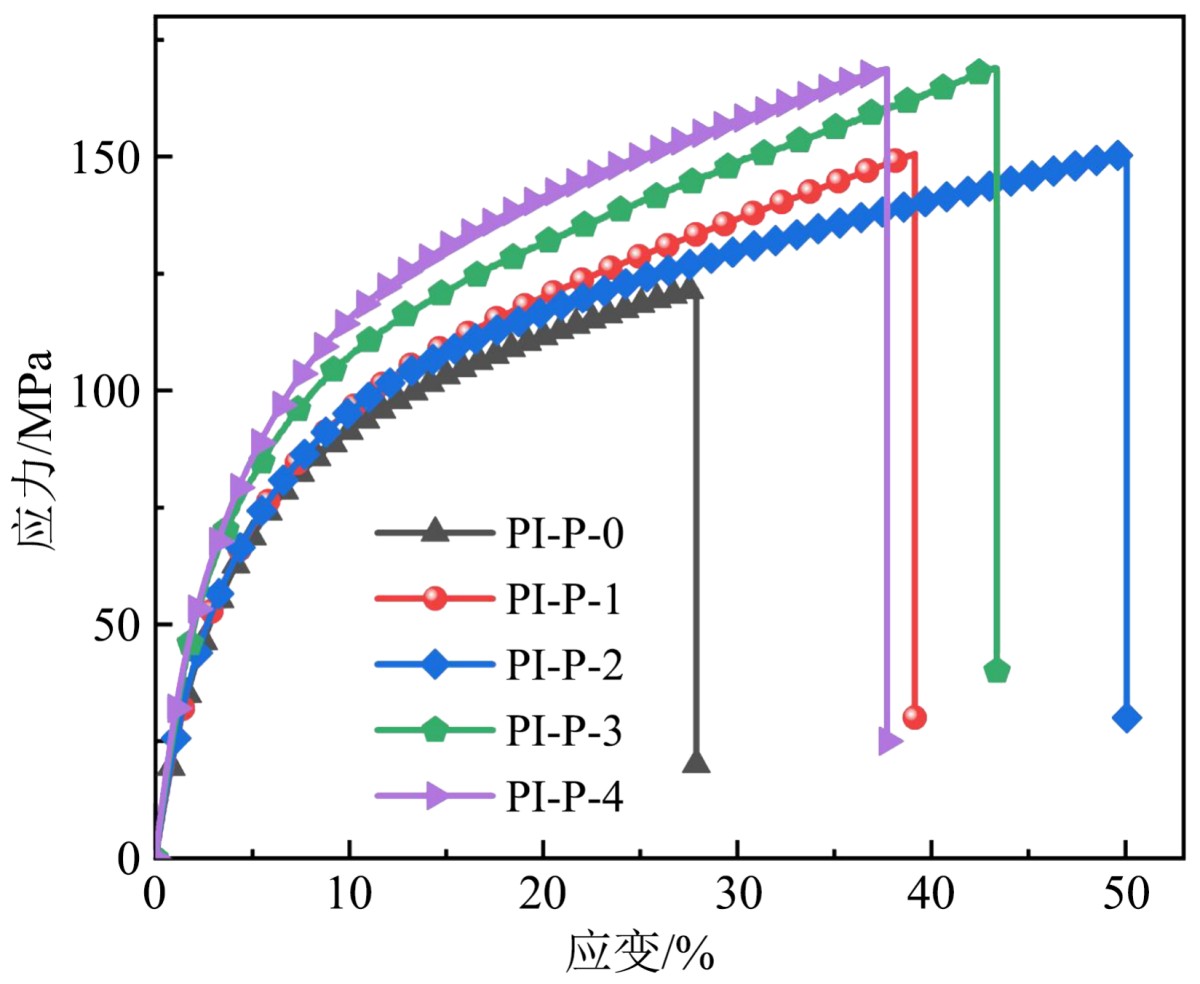

The film tensile strength ranges from 147.3 to 168.5 MPa, with an elastic modulus of 2.5 to 3.1 GPa. The introduction of APAB enhances molecular chain rigidity and promotes compact packing; however, excessive APAB (>30%) reduces the elongation at break. PI-P-1 maintains high strength while exhibiting an elongation at break of approximately 50%, balancing toughness and rigidity.

(a) Tensile strength and elastic modulus

(b) Stress-strain curve

Figure 4 Mechanical properties test results of high-temperature resistant PI coating

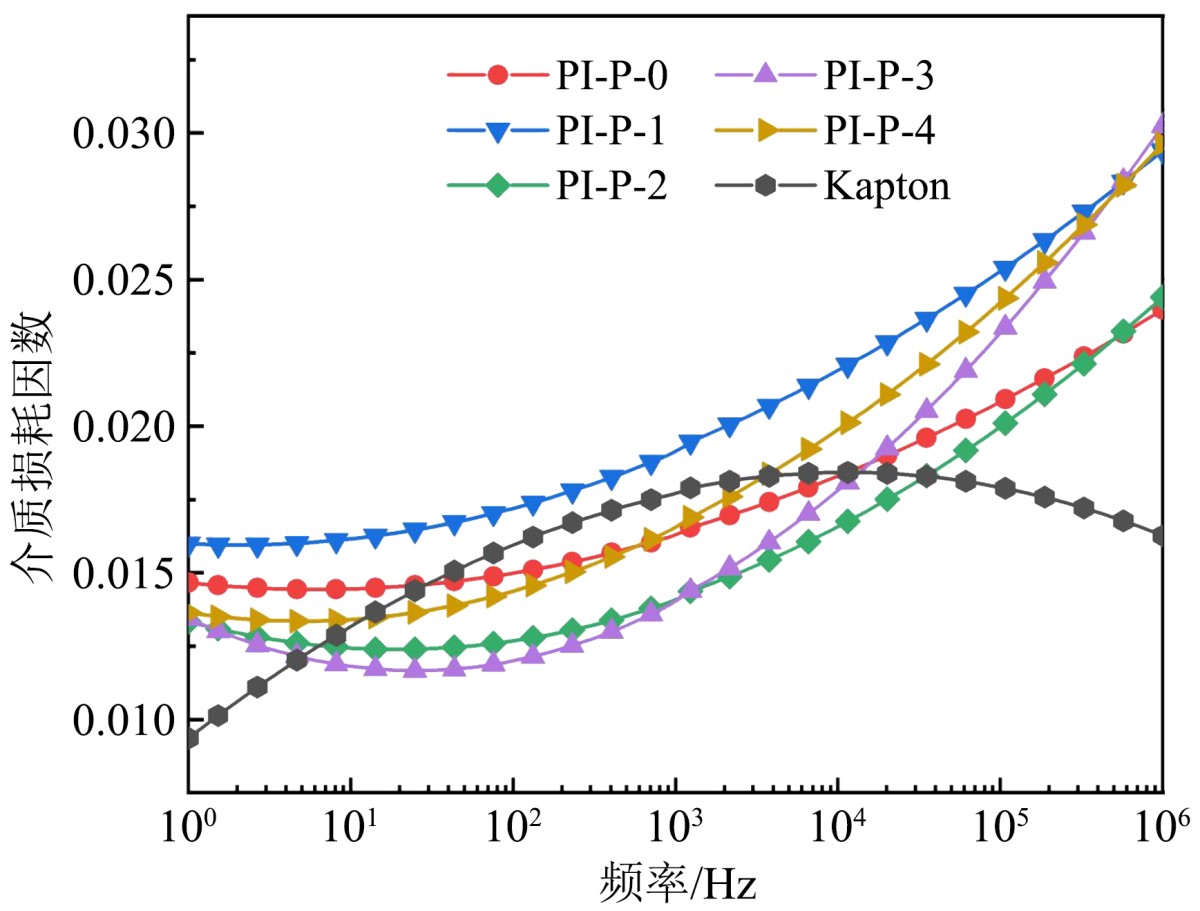

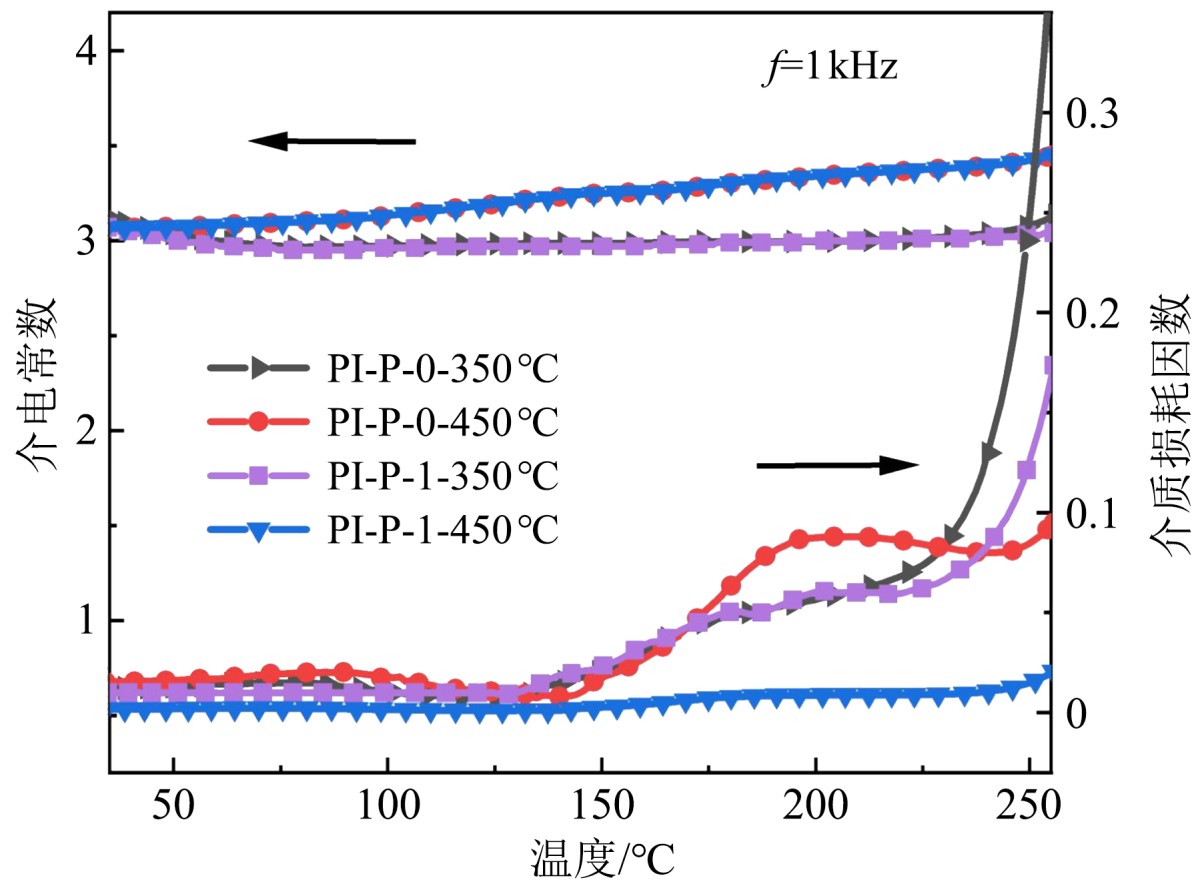

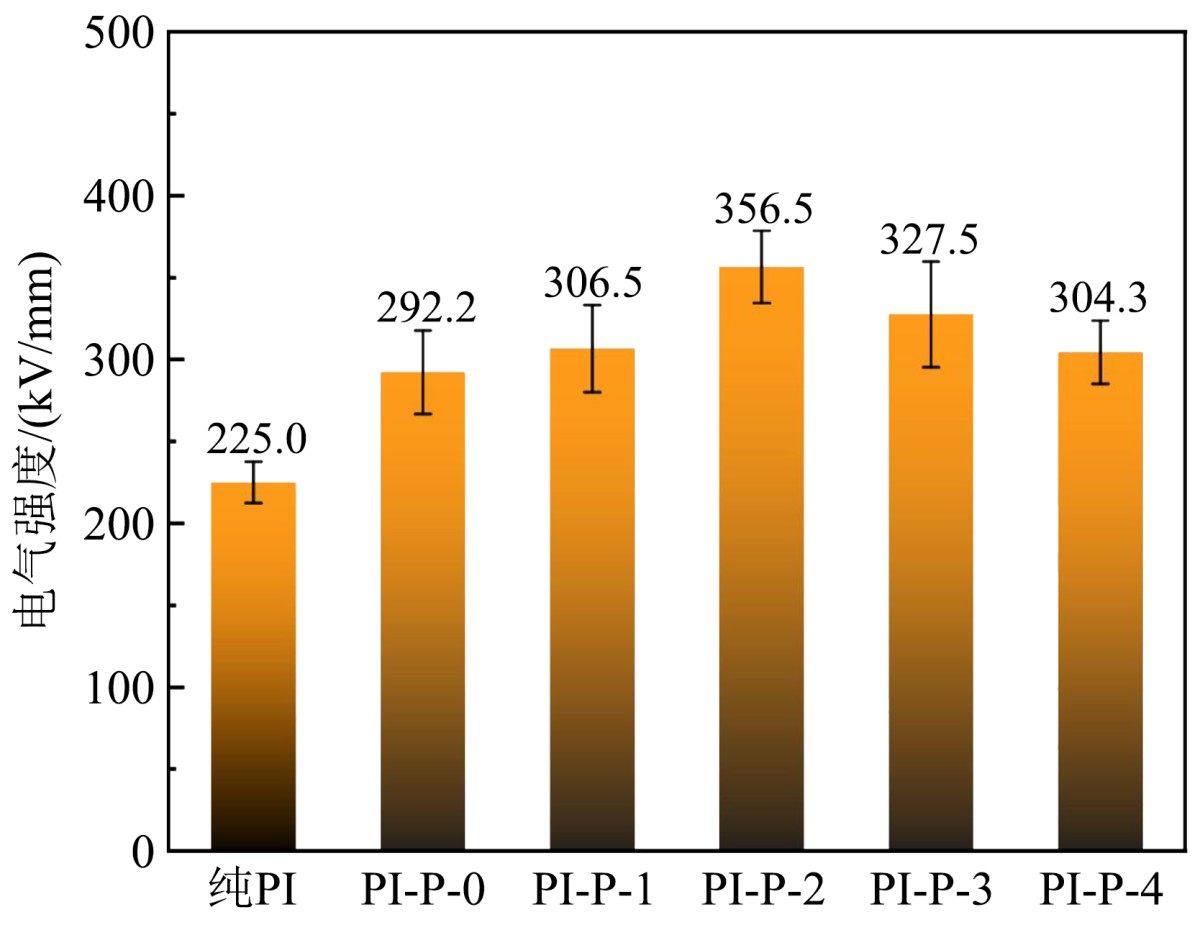

3.The electrical properties demonstrate stable and reliable performance:

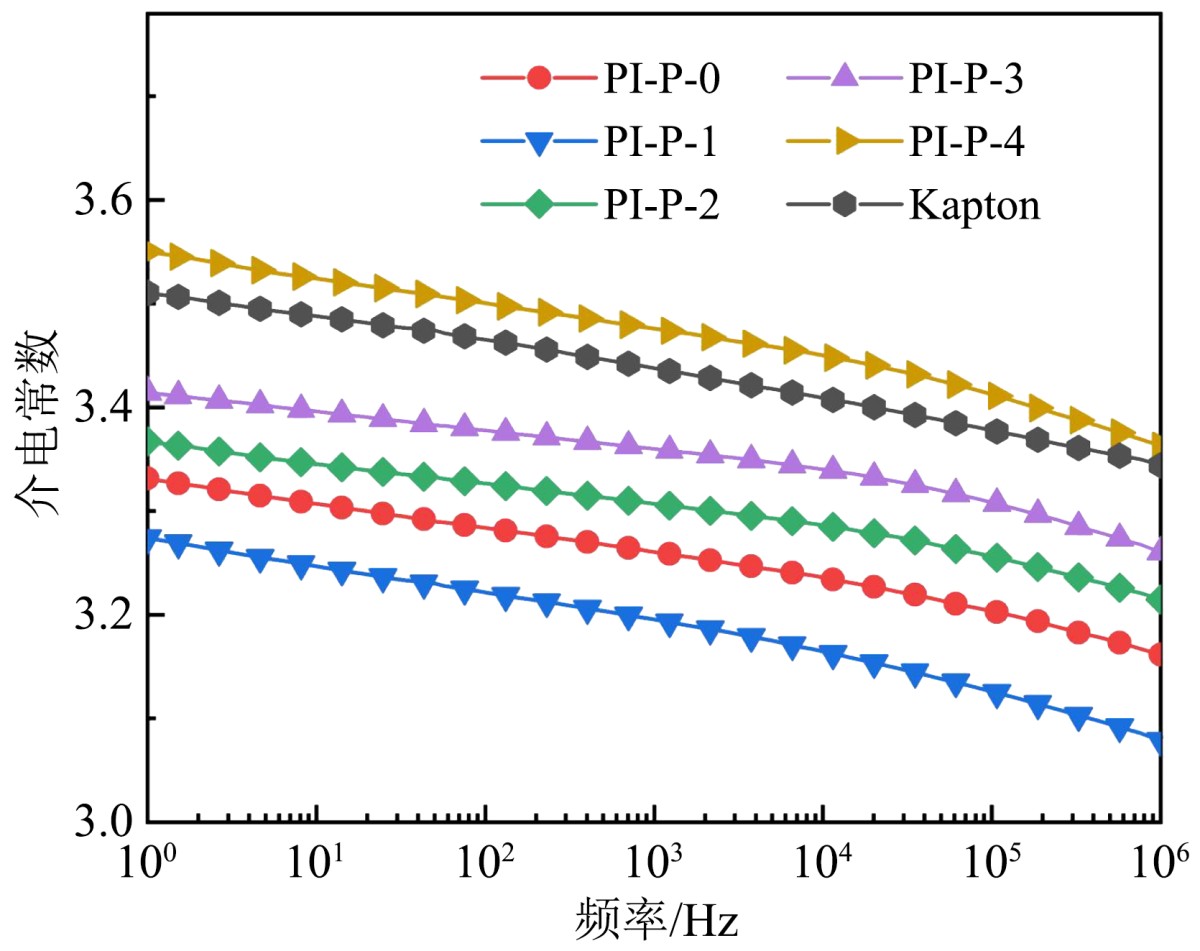

At room temperature, the dielectric constant is below 3.48 (1 kHz), with a dielectric loss factor of less than 0.019. During temperature variation tests, the PI-P-1 film exhibits optimal dielectric temperature stability at 450°C, with suppressed secondary relaxation phenomena. The electrical strength ranges from 304.3 to 356.5 kV/mm, with PI-P-2 achieving the highest value (356.5 kV/mm), attributed to increased molecular chain stacking density.

(a) dielectric constant

(b) Dielectric loss factor

(c) Temperature-dependent dielectric curve

(d) Electrical strength

Figure 5 Electrical performance test results of high-temperature-resistant PI coating

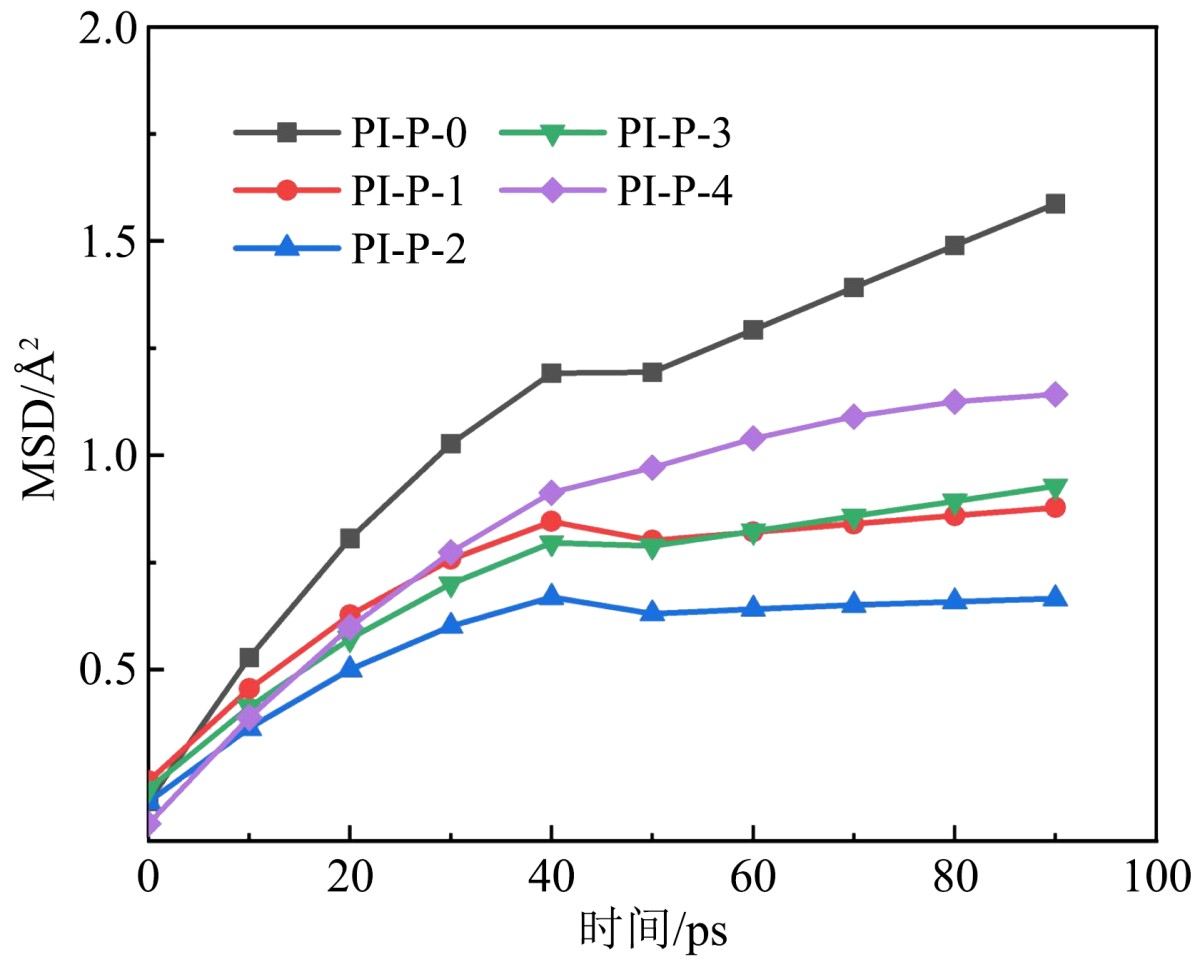

Molecular simulation reveals the mechanism

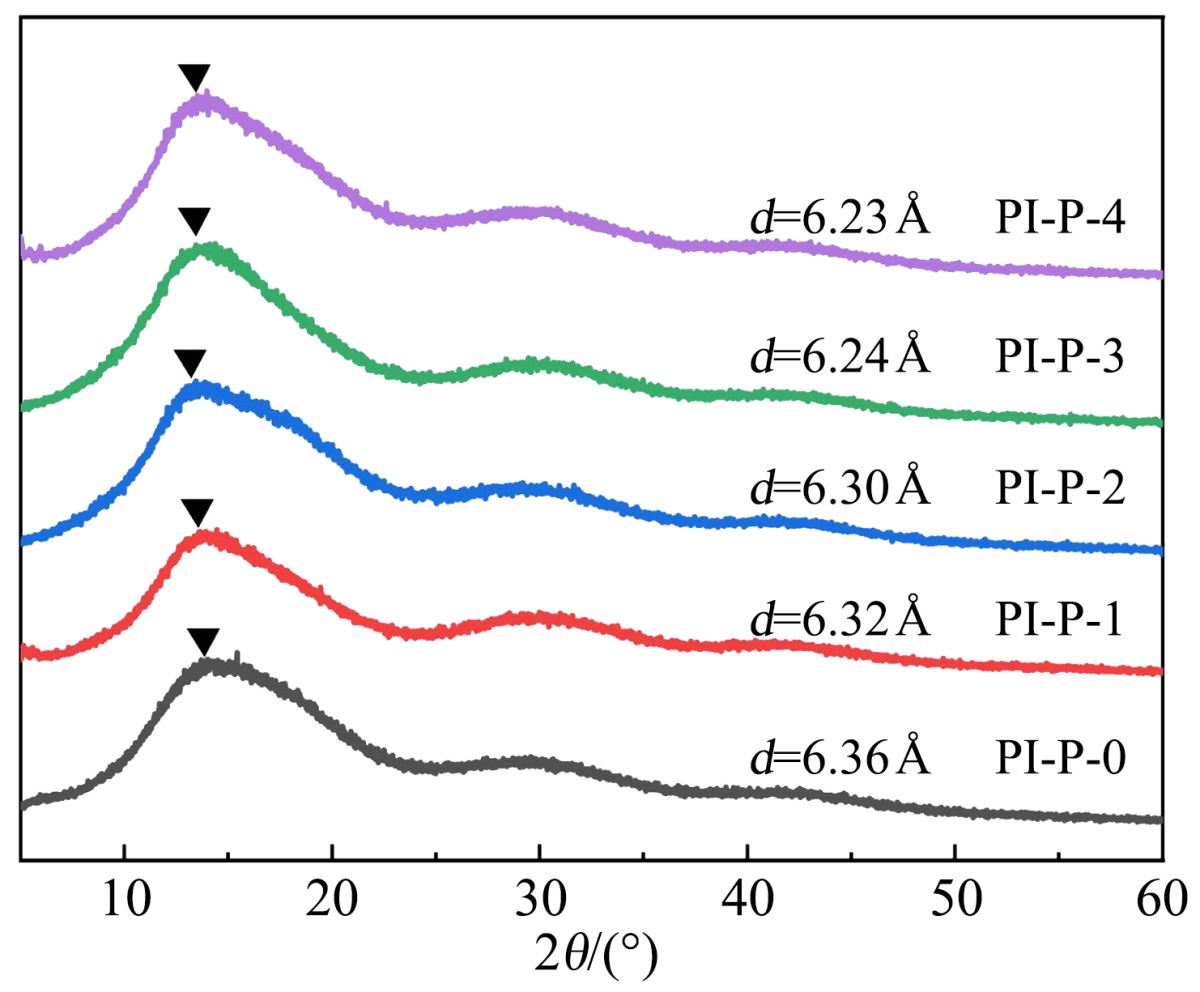

Materials Studio simulations demonstrate that APAB reduces molecular chain mobility (decreased diffusion coefficient), while XRD confirms reduced intermolecular chain spacing and tighter stacking. This explains the enhanced heat resistance and dielectric stability of the paint film.

(a)MSD curve

(b)XRD bear fruit

Figure 6 Mean Square Deviation of Different PI Structural Models and XRD Results

conclusion

This study successfully addressed the high-viscosity challenge of PI insulating paint through an "latent" intermediate strategy, while achieving synergistic optimization of thermal, mechanical, and electrical properties in the paint film. The optimal formulation PI-P-1 (10% APAB content) demonstrated outstanding comprehensive performance: Tg> 420°C, tensile strength of 147.3 MPa, dielectric constant <3.48, and excellent processability. This achievement provides a new material option for the insulation system of new energy vehicle motors, which is expected to drive the development of high-performance motors.

Future work could further optimize monomer ratios and explore industrial-scale production processes to facilitate technological upgrades in insulation materials.

GaoMi HongXiang Electromechanical Technology Co., Ltd. is a private enterprise specializing in global customer services. The company provides three core product lines: power transformer assembly manufacturing, electrical insulation paperboard, insulation laminated wood, and insulation component processing, supported by AI-driven specialized machinery. As a comprehensive provider, it integrates R&D design, production, sales, installation, training, and after-sales services. Its products are widely sold domestically and exported to Southeast Asia, South America, India, Pakistan, Russia, and other regions.

NAVIGATION

MESSAGE

Request A Quote?