0000-00

The article is sourced from "Insulation Materials"

Biaxially oriented polypropylene (BOPP) capacitor film serves as the core dielectric material in metallized thin-film capacitors, where surface properties directly determine the reliability and lifespan of the capacitors. As a critical post-processing step for BOPP capacitor films, corona treatment significantly improves surface performance, yet its comprehensive effects on film structure and electrical properties remain unclear. In their study "The Impact of Corona Treatment on the Structure and Performance of Biaxially Oriented Polypropylene Capacitor Films," published in the 10th issue of 2025 of *Insulating Materials*, Wang Jinqing et al. from Quanzhou Jiadeli Electronic Materials Co., Ltd. conducted systematic experiments to elucidate the mechanisms by which corona treatment intensity affects the physical structure, chemical structure, surface energy, and electrical properties of BOPP capacitor films.

Research Background and Objectives

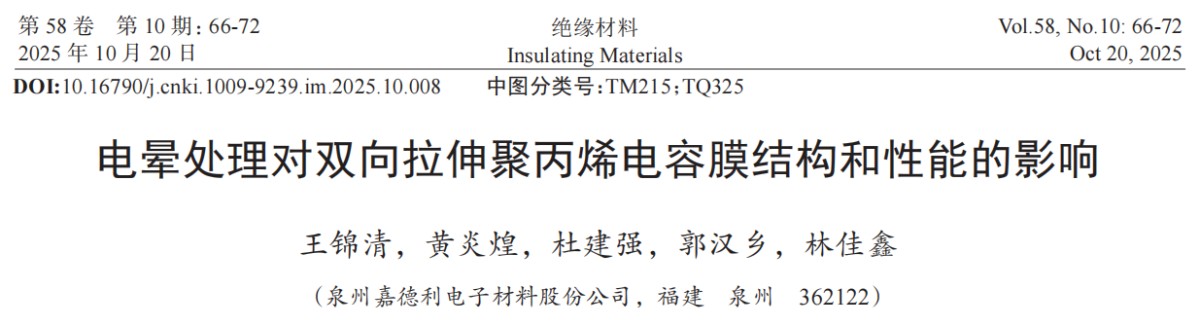

BOPP capacitor films are widely used in new energy vehicles and smart grids due to their high electrical strength (>500 V/μm) and excellent self-healing properties. However, the nonpolar molecular chains of polypropylene result in low surface energy and poor adhesion of metal coatings. Corona treatment, which introduces polar groups onto the film surface through plasma bombardment, is a common technique to enhance surface energy. This study systematically analyzes the effects of corona treatment intensity (0 W, 15 W, 30 W min/m²) on the microstructure and macroscopic properties of BOPP capacitor films, providing a basis for process optimization of high-performance capacitor films.

Figure 1 Schematic diagram of film corona treatment process

Experimental Design and Methods

This study investigates the preparation of 2.4 μm-thick BOPP ultra-thin films on industrial-grade biaxially oriented production lines, with fixed stretching process parameters and only adjusted corona intensity:

Sample grouping: 0 W (no corona), 15 W, 30 W corona treatment.

Representation:

▪Crystal structure: Differential scanning calorimetry (DSC) was used to analyze the melting curve and crystallinity.

▪Surface morphology: Surface roughness (Ra, Rz, Sz) was measured by 3D optical profilometer.

▪Chemical structure: Fourier transform infrared spectroscopy (FTIR) was used to detect polar groups.

▪Performance test: surface wetting tension, mechanical properties, dielectric spectrum, DC electrical strength (Weibull distribution fitting).

Single Strut Forming Machine

This equipment is used for chamfering the support bars of transformers. lt can process T-shaped, dove-tailed, swallow-tailed, rectangular,and other combinations of shapes for forming support bars.

Effect of Corona Treatment on Thin Film Structure

1. Physical structure: Alteration of surface morphology, stable crystal structure

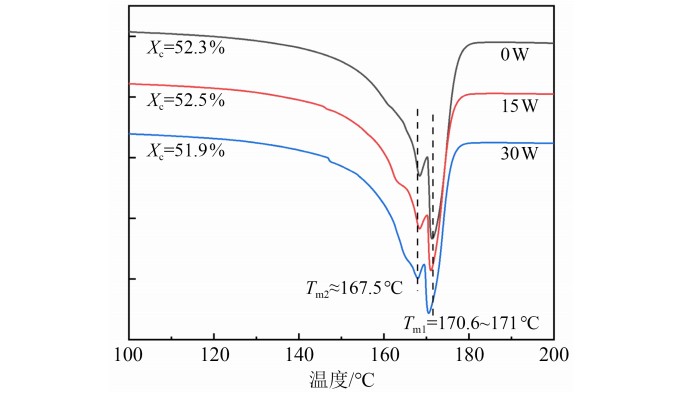

(1) Consistency of crystal structure: DSC results show that the crystallinity of the three films is about 52%, and the melting peak position (Tm1≈170.6 C, Tm2≈167.5 C) has no significant change, indicating that the corona treatment does not change the crystal structure of the films.

(2) Surface roughness reduction: The corona treatment induces physical bombardment on the film's corona-receiving surface (CR surface), resulting in a decrease in surface microstructure height. For instance, the ten-point height (Sz) of the 30 W corona-treated film decreased from 860.8 nm at 0 W to 709.6 nm (a reduction of 17.6%), while the arithmetic mean height (Rz) decreased by 11.4%. In contrast, the roughness of the air knife surface (AK surface) showed no significant change, highlighting the localized effect of the corona treatment.

Figure 2 DSC melting curves of films with different corona intensities

2. Chemical structure: Introduction of polar groups, resulting in increased surface energy

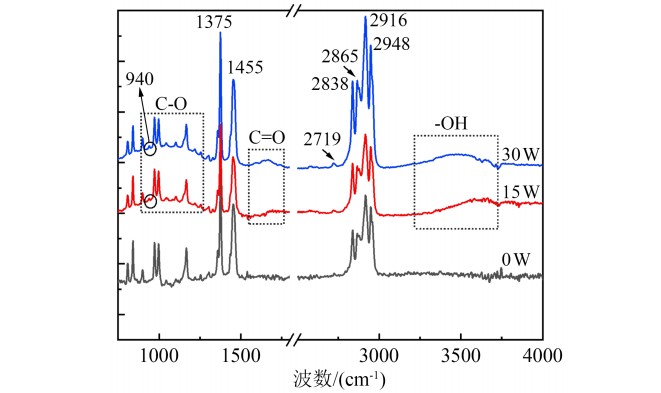

The FTIR spectra revealed that the corona treatment generated multiple polar bonds on the film surface.

(1) Characteristic peaks: A C-O bond stretching vibration peak appears at 1000~1300 cm⁻¹, a carbonyl (C=O) peak at 1600~1800 cm⁻¹, a hydroxyl (-OH) peak at 3200~3600 cm⁻¹, and a minor epoxy group peak at 940 cm⁻¹.

(2) Correlation of intensity: The increase of the intensity of corona discharge leads to the increase of the area of the polar peak, which indicates that the higher corona intensity can introduce more polar groups with high bond energy, and fundamentally improve the chemical activity of the film surface.

Figure 3 FTIR spectra of films with different corona intensities

Effect of Corona Treatment on Properties of Thin Film

1. Surface Wetting Tension and Process Performance

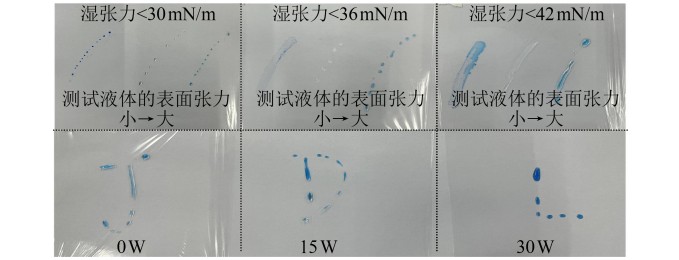

(1) Significant enhancement of wetting tension: Through droplet tests, the wetting tension of 0 W, 15 W, and 30 W films were <30 mN/m, <36 mN/m, and <42 mN/m, respectively. The corona treatment facilitated droplet spreading, demonstrating an increase in surface energy.

(2) Improved winding efficiency: Uncoronated films exhibit low surface energy, leading to easy slippage or even damage during winding. In contrast, corona-treated films demonstrate enhanced adhesion, resulting in tighter winding and ensuring production safety.

Figure 4 Comparative test of surface wetting tension for films with different corona intensity

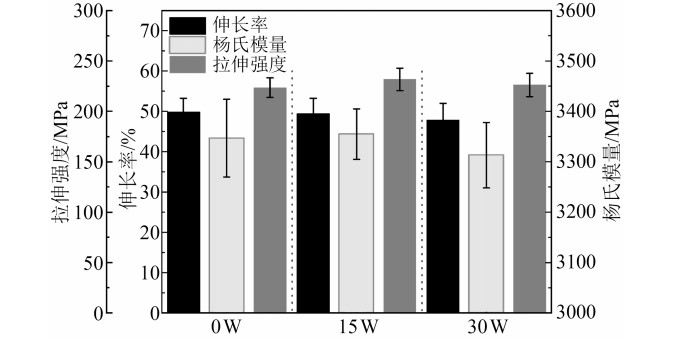

(3) Mechanical properties are stable: The corona treatment has no obvious effect on the tensile strength, elongation and modulus of the film, which indicates that the modification is limited to the surface layer.

Figure 5 Mechanical properties of films with different corona intensity

2.Dielectric properties: Delayed high-temperature decay

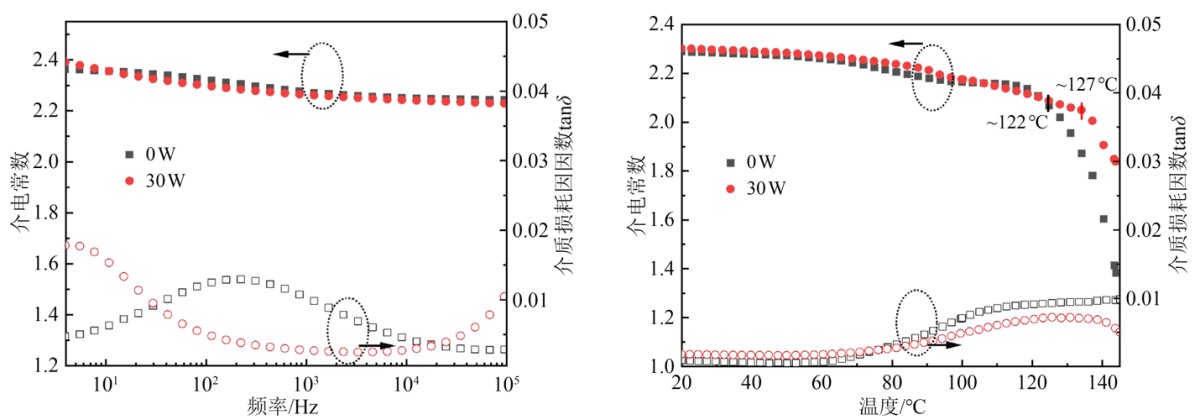

The dielectric constant of the 30 W corona film is stable at 2.2~2.4 at room temperature. The dielectric constant of the 30 W corona film is attenuated more slowly at 120℃ and above, and the dielectric loss peak changes with a lag, which indicates that the polar groups improve the dielectric stability of the 30 W corona film at high temperature.

Figure 6 (a) Frequency-dependent dielectric spectra and (b) temperature-dependent dielectric spectra of uncorona-treated and 30 W corona-treated films at room temperature

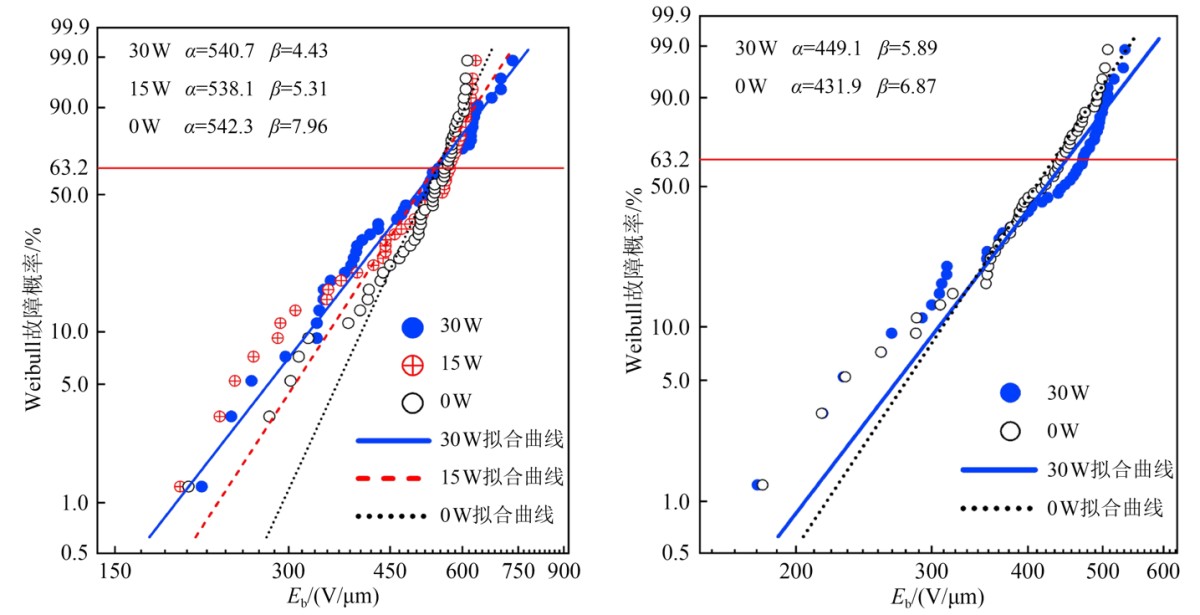

(1) Minimal variation in room temperature electrical strength: The Weibull distribution parameter α (characteristic electrical strength) of the three films fluctuates within ±5 V/μm.

(2) Weak improvement of high temperature performance: At 100℃, the electrical strength of the 30 W corona-treated film is approximately 17 V/μm higher than that of the untreated film, attributed to the deep-level traps introduced by polar groups for charge trapping.

(3) Decreased stability: The corona treatment reduced the Weibull parameter β (dispersion) from 7.96 (0 W) to 4.43 (30 W), indicating a more dispersed electrical strength distribution. Analysis suggests that a small number of strong traps lead to uneven electric field distribution, inducing field distortion.

Figure 7 Weibull distribution fitting of electrical strength: (a) at room temperature, (b) at 100°C

Research conclusion and engineering significance

(1) Structural effects: Corona treatment does not alter the crystal structure but reduces the physical height of the corona surface; it significantly modifies the chemical structure by introducing polar bonds such as C-O and C=O.

(2) Performance balance:

▪Advantages: Enhances wetting tension (ensuring metallization adhesion and winding safety), and delays high-temperature dielectric decay.

▪Risk: The electrical strength dispersion increases, which affects long-term stability.

(3) Process recommendations: The corona intensity should be optimized to balance surface energy improvement with electrical stability, avoiding over-treatment.

This study provides critical data support for enhancing the performance of BOPP capacitor films, paving the way for future exploration of synergistic effects between corona treatment and other modification techniques.

Gao Mi Hong Xiang Electromechanical Technology Co., Ltd. is a private enterprise specializing in global customer services. The company provides three core product lines: power transformer assembly manufacturing, electrical insulation paperboard, insulation laminated wood, and insulation component processing, along with EVA molding services. It also supports AI-powered specialized machine manufacturing. As a comprehensive provider, it integrates R&D design, production, sales, installation, training, and after-sales services. Its products are widely sold domestically and exported to Southeast Asia, South America, India, Pakistan, Russia, and other regions.

NAVIGATION

MESSAGE

Request A Quote?