0000-00

Discover the critical technical requirements and international standards for insulating cardboard in transformer manufacturing. As a leading Transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang specializes in high-performance electrical cardboard and Transformer insulation components. This guide explores essential material properties, processing techniques, and quality benchmarks for transformer core insulation - vital knowledge for procurement specialists, engineers, and quality control professionals in the power equipment industry.

Technical Performance of Insulating Cardboard for Transformers

The electrical cardboard used in transformer cores must meet stringent technical specifications to ensure reliable performance under high voltage and thermal stress. Key parameters include dielectric strength (typically 12-25 kV/mm), density (1.0-1.3 g/cm³), and moisture absorption rate (less than 5%). Our manufacturing process at Gaomi Hongxiang incorporates advanced cellulose purification techniques that achieve superior oil impregnation characteristics - a critical factor for large power transformers operating at 220kV and above.

International Standards and Certification

Transformer insulation components must comply with multiple international standards including IEC 60641 (pressboard and presspaper), IEEE C57.12.91 (test code for dry-type transformers), and GB/T 19264 (Chinese national standard for electrical pressboard). Our production facilities maintain ISO 9001:2015 certification with specialized testing equipment for measuring partial discharge, thermal aging resistance, and mechanical compression strength - parameters that directly impact transformer lifespan and safety.

Procurement Considerations for Transformer Core Materials

When sourcing electrical cardboard for transformer manufacturing, technical buyers should evaluate: 1) Material consistency across production batches 2) Customization capabilities for special geometries 3) Environmental compliance documentation 4) Supplier's quality control processes. Gaomi Hongxiang's vertically integrated production allows precise control over fiber orientation and density gradients - advantages particularly valuable for high-frequency transformer applications where eddy current losses must be minimized.

Case Study: 500MVA Power Transformer Project

Our insulating laminated wood solution was implemented in a recent Southeast Asian substation project requiring 500MVA/400kV transformers. The customized 8-layer phenolic laminate construction with controlled resin content (42±2%) demonstrated exceptional performance: 15% lower hot-spot temperature compared to conventional materials, verified through thermal imaging during load testing. This case highlights our capability to engineer Transformer insulation parts for extreme operating conditions.

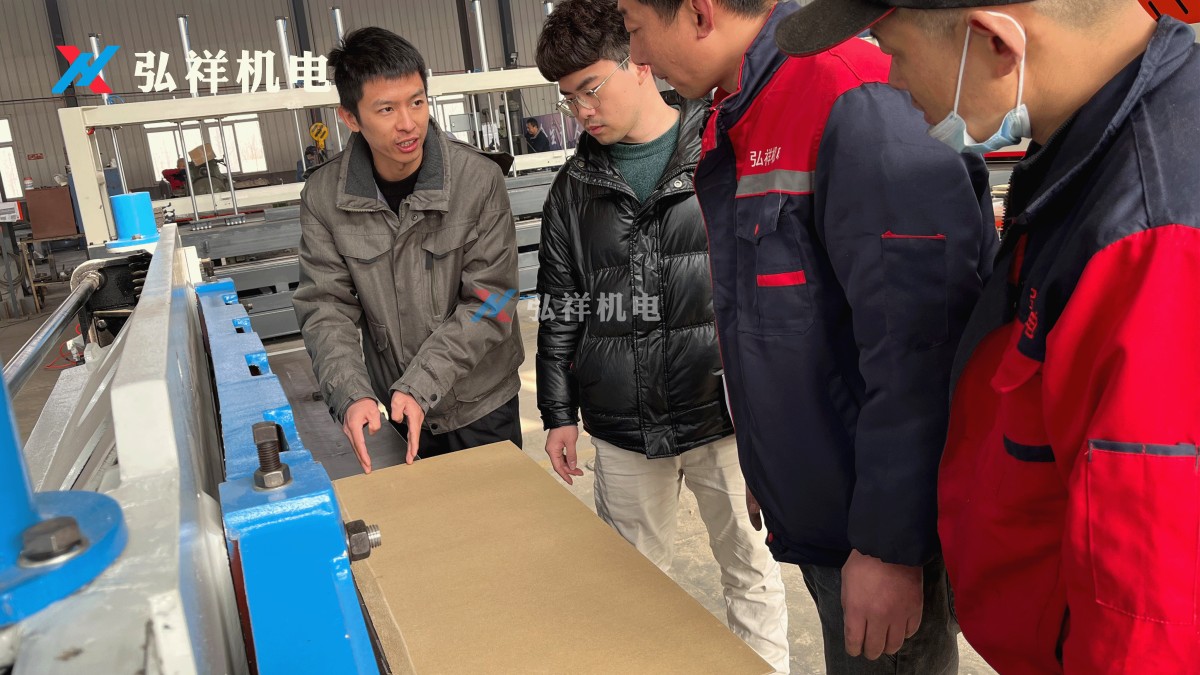

Why Choose Gaomi Hongxiang?

As a specialized Transformer insulation parts processing equipment manufacturer in China with 18 years of industry experience, we offer: 1) Proprietary EVA molding technology for complex geometries 2) In-house R&D center for material innovation 3) Complete traceability from raw materials to finished products 4) Technical support throughout the product lifecycle. Our export experience across 23 countries ensures we understand diverse regional standards and application requirements.

For technical specifications or to discuss your transformer insulation requirements, contact our engineering team at +86-XXX-XXXXXXX or visit www.hongxiangelectrical.com. We provide sample testing and customized solutions for all power transformer classes from distribution to ultra-high voltage applications.

NAVIGATION

MESSAGE

Request A Quote?