0000-00

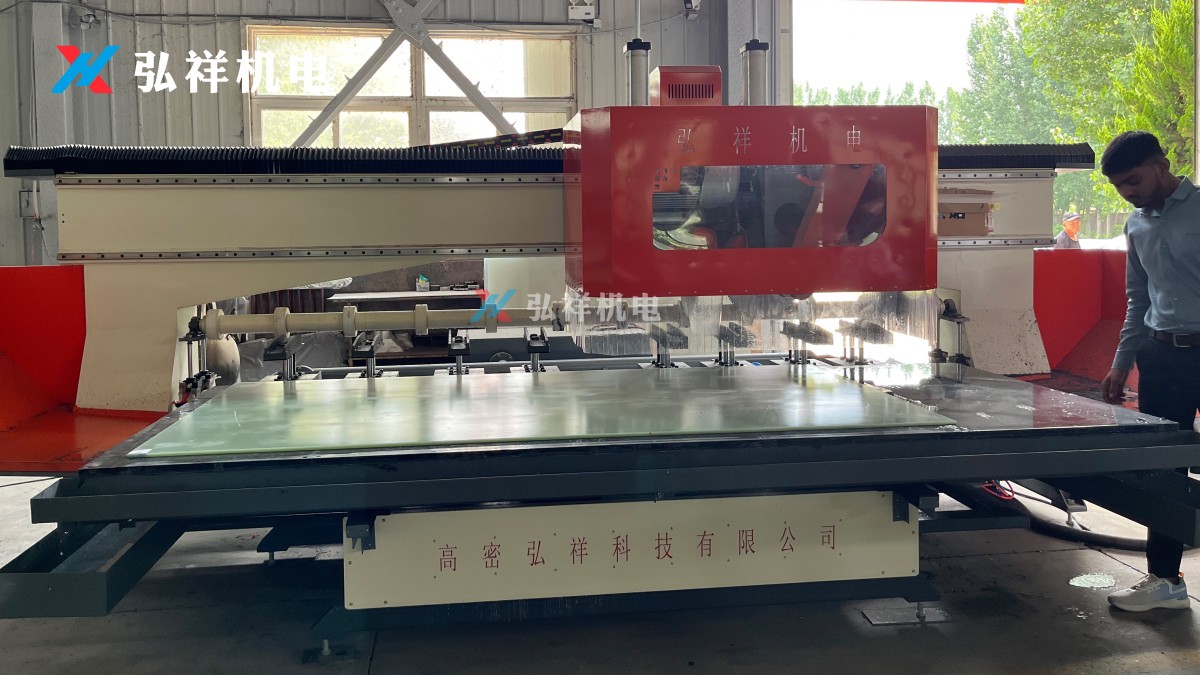

Discover precision-engineered transformer insulation parts processing equipment for laminated wood, EVA molding, and electrical insulation applications. As a leading Chinese manufacturer, we specialize in bulk orders, OEM services, and custom CNC solutions to meet your exact specifications. Our high-performance machinery is designed for technical professionals, procurement teams, and decision-makers seeking reliable, cost-effective solutions for power transformer component production.

Critical Requirements for Laminated Wood Processing in Transformer Insulation

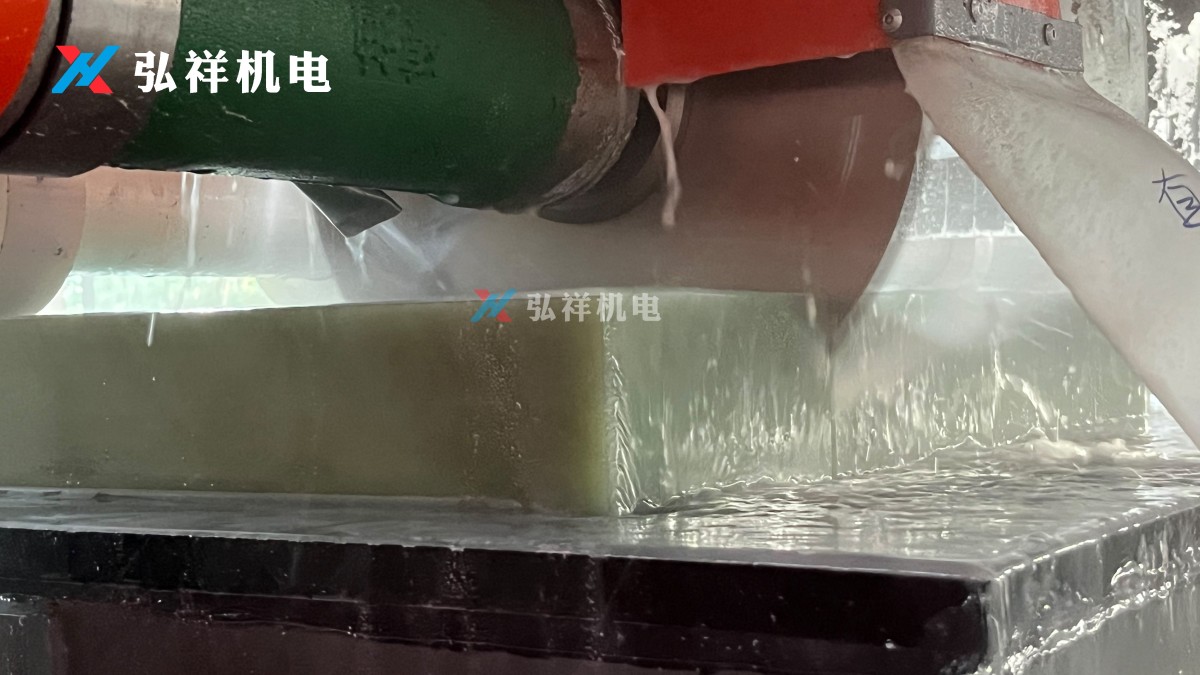

The manufacturing of transformer insulation parts from laminated wood demands specialized equipment capable of meeting stringent electrical and mechanical specifications. High-density laminated wood, often composed of birch or beech veneers bonded with phenolic resin, requires precision cutting, drilling, and surface finishing to ensure optimal dielectric strength and dimensional stability. Key machinery must feature advanced CNC controls for micron-level accuracy, as even minor deviations can compromise insulation performance. Thermal stability is another critical factor, with processing equipment needing to maintain consistent temperatures during machining to prevent delamination or resin degradation. Dust extraction systems are equally vital to maintain workshop safety and prevent conductive particle contamination. For bulk order production, automated material handling systems significantly enhance throughput while maintaining quality consistency across large batches.

EVA Molding Solutions for Transformer Insulation Components

Ethylene-vinyl acetate (EVA) molding has become increasingly prevalent in transformer insulation manufacturing due to its excellent dielectric properties and flexibility. Specialized processing equipment for EVA applications requires precise temperature control zones, typically between 80°C to 120°C, to ensure proper cross-linking without material degradation. Hydraulic or electric injection molding machines with clamping forces ranging from 150 to 600 tons are commonly employed, depending on component size and complexity. The equipment must accommodate various EVA formulations with different vinyl acetate content (typically 18%-28%), requiring adjustable processing parameters. Advanced mold designs incorporate cooling channels and venting systems to prevent air traps that could create weak points in the insulation. For OEM service providers, modular mold systems allow rapid changeovers between different transformer part geometries, significantly reducing downtime during production runs.

CNC Technology Advancements in Insulation Part Manufacturing

Modern CNC transformer insulation parts processing equipment represents a quantum leap in precision and efficiency for electrical insulation component production. Five-axis CNC routers with spindle speeds up to 24,000 RPM can achieve surface finishes below 1.6μm Ra on laminated wood, critical for preventing partial discharge. Adaptive toolpath algorithms automatically compensate for material density variations in natural wood products, ensuring uniform machining depth. Dust-proof linear guides and ball screws extend maintenance intervals in the abrasive machining environment of composite materials. For complex geometries like winding spacers or lead exit supports, simultaneous five-axis machining eliminates secondary operations, reducing production time by up to 40%. The integration of in-process measurement systems allows real-time quality verification, particularly valuable for custom transformer insulation parts processing equipment where first-article inspection is crucial.

Quality Assurance in Electrical Insulation Manufacturing

Transformer insulation parts processing equipment for electrical insulation applications must incorporate robust quality control mechanisms throughout production. Dielectric testing stations integrated into the production line can verify insulation integrity at various processing stages, typically applying test voltages between 2kV to 15kV depending on the final application. Moisture content monitoring systems ensure laminated wood components maintain equilibrium moisture content (EMC) within 6-8% to prevent dimensional instability in service. For EVA-molded parts, infrared spectroscopy units can verify polymer cross-linking density, a critical parameter affecting long-term thermal stability. Automated optical inspection (AOI) systems with resolution down to 10μm detect surface imperfections that could initiate corona discharge. These quality systems are particularly crucial when sourcing transformer insulation parts processing equipment for high-voltage applications (≥72.5kV), where failure modes can have catastrophic consequences.

Global Sourcing Considerations for Transformer Manufacturing Equipment

When evaluating transformer insulation parts processing equipment manufacturers in China or other global markets, several technical and commercial factors warrant careful consideration. Equipment should comply with international standards such as IEC 60641 for pressboard and laminated wood, or IEC 60893 for industrial laminated sheets. Lead times for custom CNC transformer insulation parts processing equipment typically range from 12-20 weeks, including factory acceptance testing (FAT). Total cost of ownership calculations should account for energy efficiency (many modern machines reduce power consumption by 30-40% compared to previous generations), tooling costs, and expected maintenance intervals. For bulk order scenarios, verify the manufacturer's capacity to support annual production volumes of 50,000+ components without quality degradation. Technical documentation packages should include detailed risk assessments per ISO 12100 for machinery safety, along with CE or other region-specific certifications as required by your target markets.

Conclusion and Next Steps

Selecting optimal transformer insulation parts processing equipment requires balancing technical specifications, production requirements, and total cost considerations. Whether your focus is laminated wood components, EVA molding applications, or custom electrical insulation solutions, partnering with an experienced manufacturer ensures access to both standard and specialized machinery configurations. As a leading transformer insulation parts processing equipment manufacturer in China, we combine advanced CNC technology with deep material science expertise to deliver solutions meeting international quality standards. Our engineering team can provide detailed application analysis to recommend the most efficient equipment configuration for your specific production volumes and technical requirements.

Contact our technical sales team today to discuss your transformer insulation manufacturing needs and request a customized equipment proposal tailored to your production environment and quality standards.

NAVIGATION

MESSAGE

Request A Quote?