0000-00

Introduction to Electrical Cardboard Performance Testing in High-Voltage Transformers

Discover essential performance testing methods for electrical cardboard in high-voltage transformers to ensure optimal insulation and safety. As a leading transformer insulation components manufacturer in China, Gaomi Hongxiang provides cost-effective solutions for transformer core and insulating cardboard applications. This guide explores critical evaluation techniques for professionals seeking reliable transformer insulation parts processing equipment.

Why Performance Testing is Critical for Transformer Insulation Components

Electrical cardboard serves as a vital insulating material in high-voltage transformers, preventing electrical discharges and ensuring operational safety. Performance testing is essential to verify the material's dielectric strength, thermal stability, and mechanical durability under extreme conditions. For transformer manufacturers and operators, these tests help mitigate risks of electrical failures, reduce maintenance costs, and extend equipment lifespan. Gaomi Hongxiang's expertise in transformer insulation parts processing equipment enables precise evaluation of these parameters, ensuring compliance with international standards like IEC 60641 and ASTM D619.

Key Performance Testing Methods for Electrical Cardboard

1. Dielectric Strength Testing

Dielectric strength testing measures the electrical breakdown voltage of insulating cardboard when subjected to increasing voltage levels. This test determines the material's ability to withstand high-voltage stresses without failure. The procedure involves placing the sample between two electrodes in a controlled environment and gradually increasing the voltage until breakdown occurs. For transformer applications, a minimum dielectric strength of 40 kV/mm is typically required. Gaomi Hongxiang's transformer insulation components are rigorously tested to exceed this threshold, ensuring reliability in high-voltage environments.

2. Thermal Aging and Stability Tests

Thermal aging tests evaluate how electrical cardboard performs under prolonged exposure to high temperatures, simulating real-world transformer operating conditions. Samples are subjected to temperatures up to 105°C for extended periods, after which their mechanical and electrical properties are re-evaluated. Key metrics include tensile strength retention, dimensional stability, and dielectric properties post-aging. Our insulating cardboard for transformers demonstrates less than 10% degradation in dielectric strength after 1,000 hours of thermal aging, outperforming industry benchmarks.

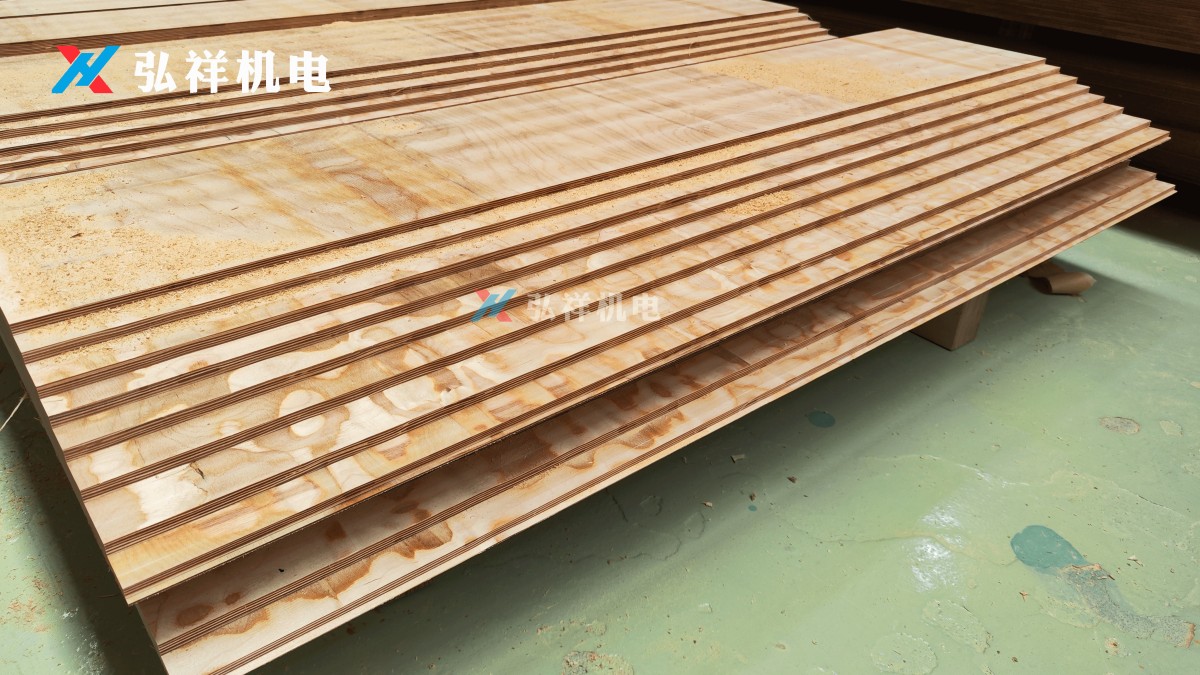

3. Mechanical Compression and Density Analysis

The mechanical integrity of transformer insulation components is critical for withstanding the compressive forces within transformer cores. Standard tests include:

- Compressive strength measurement at various humidity levels

- Density profiling across the material thickness

- Creep resistance evaluation under sustained load

Our processing equipment ensures uniform density (1.0-1.2 g/cm³) throughout the insulating cardboard, preventing weak points that could lead to premature failure in transformer applications.

Advanced Testing Equipment for Transformer Insulation Components

Gaomi Hongxiang utilizes state-of-the-art transformer insulation parts processing equipment to conduct comprehensive performance evaluations. Our testing laboratory features:

Cost-Effective Solutions for Transformer Insulation Parts Processing

As a trusted transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang offers:

- Customized equipment configurations for specific production needs

- Competitive transformer insulation parts processing equipment price lists

- Energy-efficient designs reducing operational costs by up to 30%

- Integrated quality control systems ensuring consistent output

Our solutions are particularly suitable for manufacturers serving markets in Southeast Asia, South America, and other regions with demanding transformer applications.

Conclusion and Next Steps

Comprehensive performance testing of electrical cardboard is essential for ensuring transformer reliability and safety. By implementing rigorous dielectric, thermal, and mechanical evaluations, manufacturers can prevent costly failures and extend equipment service life. Gaomi Hongxiang's expertise in transformer core insulation and advanced processing equipment provides industry-leading solutions for global customers.

For technical specifications of our insulating cardboard for transformers or to request a detailed equipment price list, contact our engineering team today. Let us help you optimize your transformer insulation components for superior performance and cost-efficiency.

NAVIGATION

MESSAGE

Request A Quote?