0000-00

Precision Engineering for Transformer Insulation Manufacturing

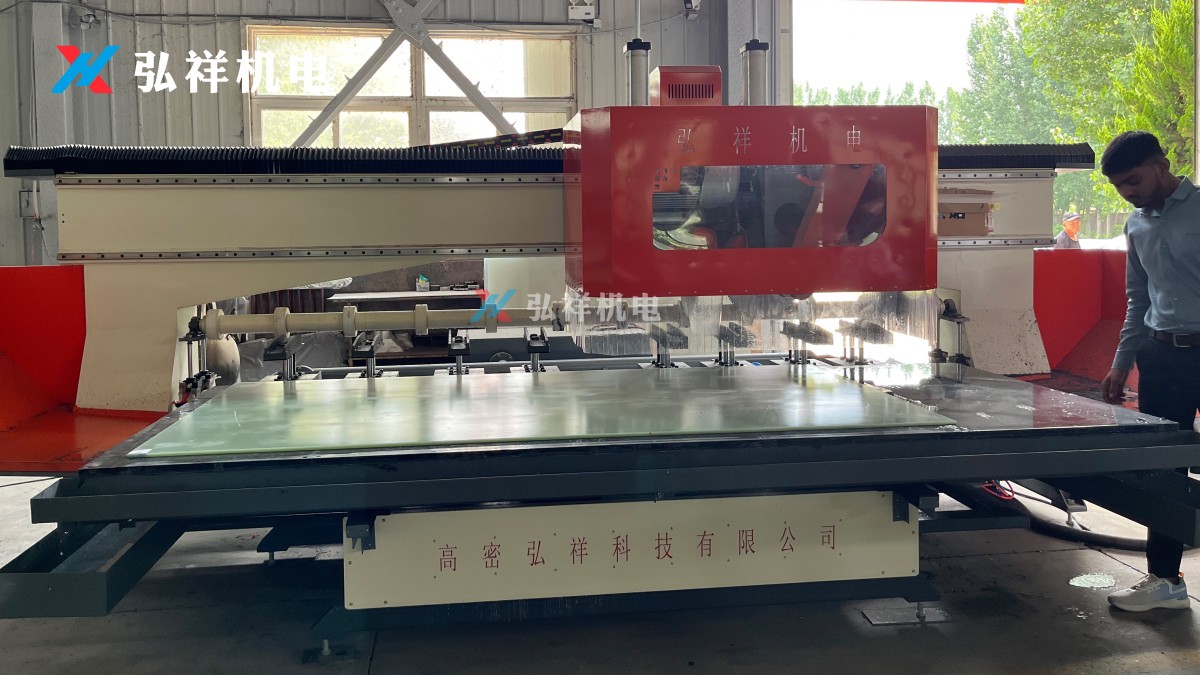

Upgrade your transformer production with precision-engineered insulation parts processing equipment from Gaomi Hongxiang. Our CNC transformer insulation parts processing equipment offers specialized solutions for EVA molding, laminated wood, and electrical insulation applications. Whether you need bulk order capabilities, OEM services, or custom configurations, our China-based manufacturing expertise delivers reliable performance for global clients. Discover how our transformer insulation parts processing equipment can optimize your operations while meeting strict quality standards.

Advanced CNC Solutions for Diverse Insulation Materials

Modern transformer manufacturing demands specialized equipment capable of handling various insulation materials with micron-level precision. Our CNC transformer insulation parts processing equipment is engineered to process electrical insulating cardboard, laminated wood, and EVA components with exceptional accuracy. The computer-controlled systems ensure repeatable quality across bulk orders while accommodating custom geometries required for high-voltage applications. For operations requiring EVA molding processing, our machines feature temperature-controlled platens and programmable pressure profiles that maintain material integrity during production cycles. The modular design allows for quick changeovers between different insulation materials, significantly reducing downtime when switching between laminated wood and composite insulation components.

Custom Manufacturing Capabilities for Global Markets

As a leading transformer insulation parts processing equipment manufacturer in China, we offer comprehensive OEM services tailored to international standards. Our engineering team collaborates closely with clients to develop custom transformer insulation parts processing equipment that addresses specific production challenges. From specialized tooling for intricate electrical insulation profiles to high-volume production systems for bulk orders, we implement robust quality control measures at every stage. The equipment incorporates safety interlocks and real-time monitoring systems that meet stringent international regulations, particularly important for clients exporting to Southeast Asia, South America, and European markets. Our sourcing specialists can advise on material selection and processing parameters for optimal performance across different climatic conditions.

Technical Specifications and Performance Metrics

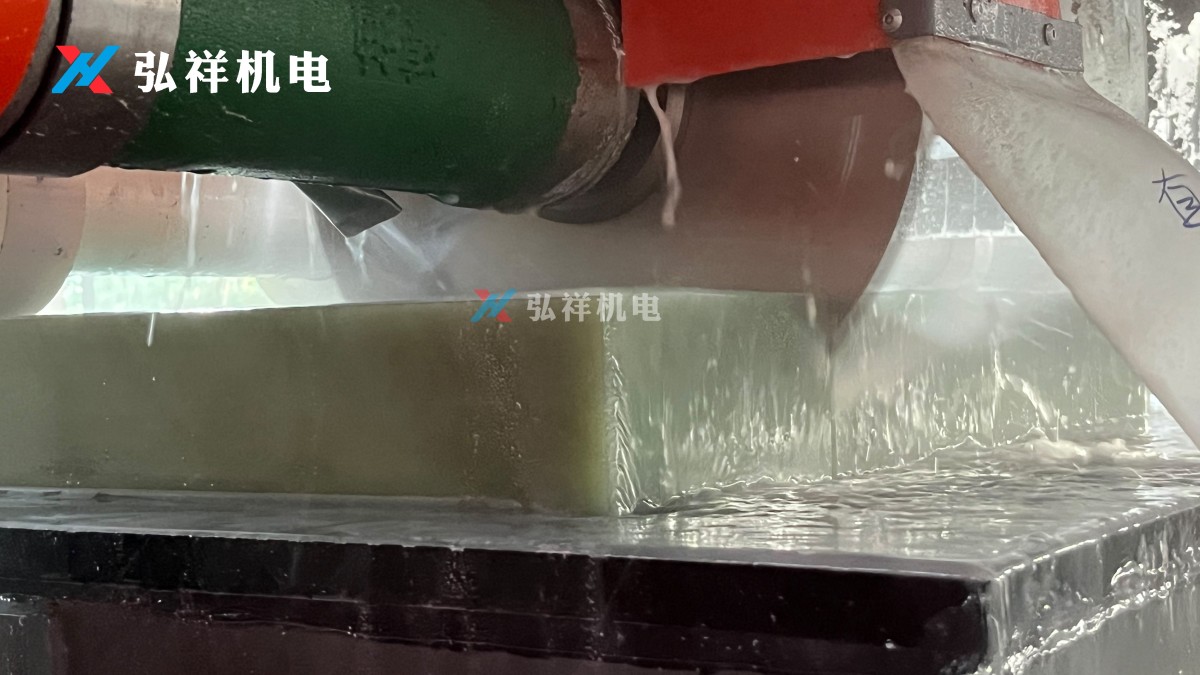

The transformer insulation parts processing equipment for laminated wood applications features servo-driven cutting systems with positioning accuracy of ±0.02mm, critical for maintaining dielectric properties in finished components. For electrical insulation production, the machines utilize laser-guided alignment systems that ensure perfect layer registration during the lamination process. Key performance indicators include:

• 98.7% uptime reliability for continuous production cycles

• Energy consumption reduced by 22% through optimized servo motor configurations

• Tool life extended by 40% using proprietary coating technologies

• Integrated quality inspection systems with 100% dimensional verification

These technical advantages make our CNC transformer insulation parts processing equipment ideal for manufacturers requiring both precision and production efficiency. The systems support Industry 4.0 connectivity for real-time production monitoring and predictive maintenance scheduling.

Comprehensive Support for Project Implementation

Successful integration of new transformer insulation parts processing equipment requires careful planning and expert support. Our project management team provides:

• Factory layout optimization for seamless production line integration

• Operator training programs covering equipment operation and safety protocols

• Preventive maintenance schedules tailored to your production volume

• Spare parts inventory planning for minimal downtime

• Technical documentation translated into multiple languages

For clients sourcing transformer insulation parts processing equipment for the first time, we offer pilot production runs to verify machine performance with your specific materials. The after-sales support network includes regional service centers in key export markets like India, Pakistan, and Russia, ensuring prompt technical assistance when needed.

Cost-Benefit Analysis for Equipment Investment

Investing in advanced transformer insulation parts processing equipment delivers measurable ROI through multiple channels:

Industry-Leading Quality Assurance Protocols

Every transformer insulation parts processing equipment unit undergoes rigorous testing before shipment, including:

• 72-hour continuous run tests under production conditions

• Dielectric strength verification for all electrical components

• Vibration analysis to ensure stable operation at rated speeds

• Thermal imaging of critical components under maximum load

• Safety system validation per CE and other international standards

The quality management system is certified to ISO 9001:2015, with additional compliance to IEC standards for electrical insulation manufacturing. For OEM service clients, we provide complete material traceability documentation and production process validation reports to support your own quality certification requirements.

Optimize Your Transformer Production Today

Gaomi Hongxiang Electromechanical Technology Co., Ltd. combines decades of transformer manufacturing expertise with cutting-edge CNC technology to deliver reliable insulation parts processing solutions. Whether you require standard configurations or custom transformer insulation parts processing equipment for specialized applications, our engineering team stands ready to develop the optimal solution for your production requirements. Contact our technical sales team today to schedule a virtual demonstration or request detailed specifications for your project evaluation. Let us help you achieve higher productivity, superior quality, and reduced operating costs through advanced manufacturing technology.

For immediate assistance with your transformer insulation parts processing equipment needs, call +86-XXX-XXXX-XXXX or email sales@hongxiang-electric.com. Explore our complete line of industrial solutions at www.hongxiang-electric.com.

NAVIGATION

MESSAGE

Request A Quote?