0000-00

When sourcing high-quality transformer insulation parts processing equipment for bulk orders or custom OEM services, precision and reliability are non-negotiable. This comprehensive quality control checklist helps technical evaluators, procurement specialists, and project managers assess CNC equipment for EVA molding, laminated wood processing, and electrical insulation applications. Whether you're a manufacturer, distributor, or end-user, these critical evaluation points ensure you select the optimal machinery from trusted Chinese manufacturers like Gaomi Hongxiang.

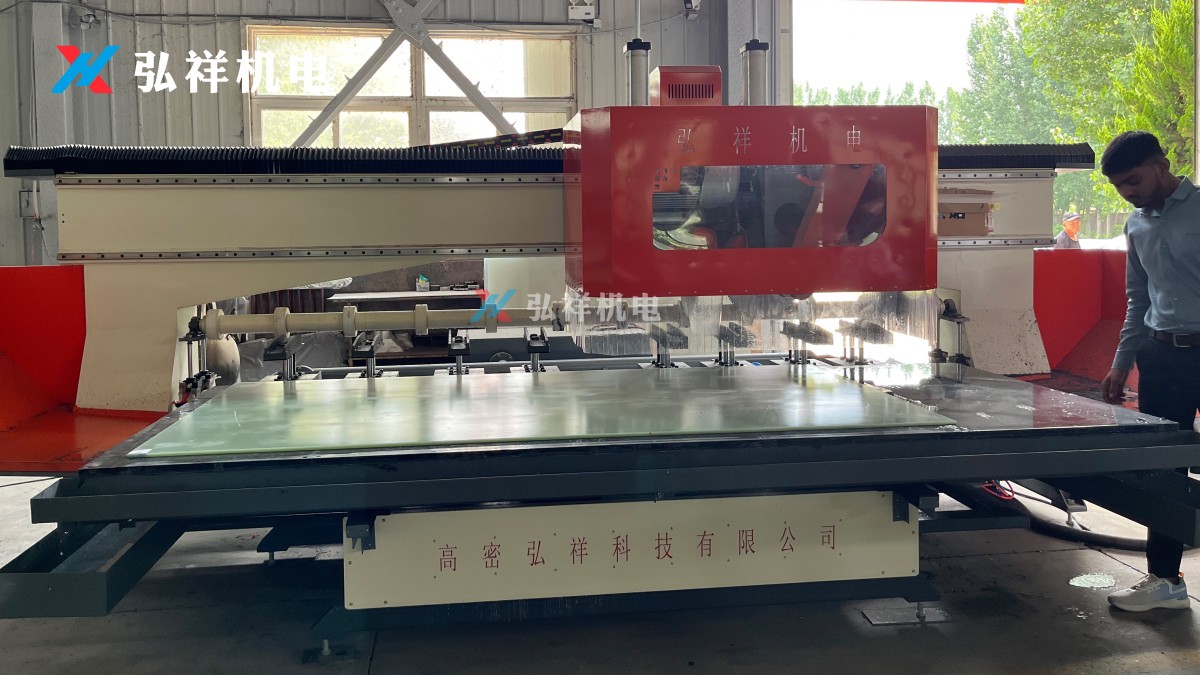

Key Specifications for Transformer Insulation Parts Processing Equipment

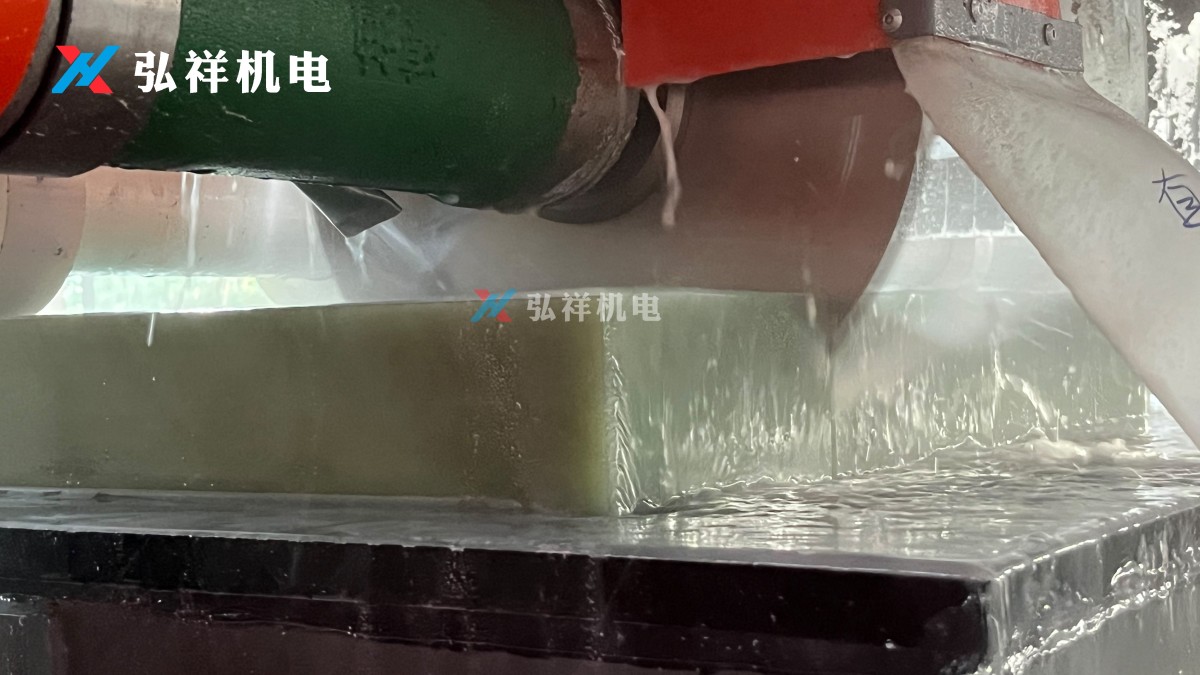

When evaluating transformer insulation parts processing equipment, technical specifications form the foundation of your quality assessment. For EVA molding applications, verify the equipment's temperature control range (typically 150-300°C) and pressure accuracy (±0.5% FS). Laminated wood processing requires examination of the CNC router's spindle speed (18,000-24,000 RPM recommended) and positioning accuracy (≤0.02mm). Electrical insulation components demand specialized attention to dielectric strength testing capabilities, with equipment needing to maintain consistent 1-5kV test voltages. The cutting precision for insulation paperboard should achieve ±0.1mm tolerance, while automated feeding systems must demonstrate 99.5% material placement accuracy. Always request factory test reports showing these parameters under continuous 72-hour operation to validate stability.

Material Compatibility and Processing Capabilities

Top-tier transformer insulation parts processing equipment must handle diverse materials without compromising output quality. For OEM service providers, verify the machine's compatibility with Nomex (410-450°C thermal class), pressboard (density 1.0-1.2g/cm³), and epoxy composites (CTI ≥600V). The equipment should offer adjustable processing parameters for different material thicknesses (0.1-50mm range ideal). When sourcing for bulk orders, confirm the simultaneous processing capacity - advanced models can handle 8-12 insulation components in one cycle. For custom transformer insulation parts processing equipment, look for modular tooling systems that allow quick changeovers between EVA molding dies, wood lamination cutters, and insulation paper punching units. The best Chinese manufacturers provide material-specific processing profiles pre-loaded in the CNC system.

Critical Safety and Compliance Standards

Transformer insulation parts processing equipment must comply with international safety standards to ensure workplace protection and product reliability. Require CE certification (including EMC Directive 2014/30/EU) and ISO 9001:2015 quality management system documentation. For electrical insulation applications, the machinery should meet IEC 60641-3 for pressboard processing and IEC 60893 for laminated wood. Dust extraction systems must achieve ≤1mg/m³ particulate levels (OSHA 1910.1000 compliance). Verify emergency stop response times (<0.5 seconds) and presence of light curtains (Type 4 per IEC 61496-1). Reputable manufacturers like Gaomi Hongxiang provide complete test certificates and third-party verification reports for all safety systems.

Production Efficiency Metrics for Bulk Orders

When procuring transformer insulation parts processing equipment for high-volume production, evaluate these operational efficiency indicators: Cycle time per component (target<90 seconds for standard insulation parts), energy consumption per unit (≤3.5kWh for EVA molding processes), and tooling changeover duration (<15 minutes for complete configuration switches). The equipment should demonstrate 92-95% uptime during validation trials. For CNC transformer insulation parts processing equipment, examine the simultaneous axis movement capability (5-axis minimum recommended) and program storage capacity (≥500 programs). Advanced models feature predictive maintenance systems that monitor spindle bearing wear, cutting tool life, and hydraulic pressure fluctuations to prevent unplanned downtime.

After-Sales Support and Technical Training

Comprehensive after-sales service differentiates premium transformer insulation parts processing equipment manufacturers. Demand 24/7 technical support availability with guaranteed 4-hour response times for critical issues. Verify the availability of local service engineers in your region - leading Chinese suppliers typically maintain teams in Southeast Asia, South America, and Eastern Europe. Training programs should cover machine operation (minimum 40 hours), preventive maintenance procedures, and troubleshooting for EVA molding defects or laminated wood processing irregularities. Ensure the manufacturer provides complete documentation including electrical schematics, hydraulic diagrams, and PLC source codes. For equipment sourcing in India, Pakistan, or Russia, confirm the availability of multilingual operation manuals and localized interface options.

Cost-Benefit Analysis for Long-Term Investment

Performing a thorough cost analysis ensures optimal ROI when purchasing transformer insulation parts processing equipment. Beyond the initial purchase price, evaluate these financial factors: Energy efficiency (compare kW/unit across models), tooling costs (dies, cutters, fixtures), and expected maintenance expenses (typically 3-5% of CAPEX annually). For custom transformer insulation parts processing equipment, calculate the payback period based on increased production capacity (often 12-18 months). Consider the equipment's upgradeability - modular systems allow future integration of AI-based quality inspection or robotic loading without complete replacement. Leading manufacturers offer financial packages including lease-to-own options and productivity-based payment plans, particularly beneficial for bulk orders exceeding $500,000.

This quality control checklist empowers technical evaluators and procurement teams to make informed decisions when selecting transformer insulation parts processing equipment. By rigorously assessing specifications, safety compliance, production efficiency, and after-sales support, you ensure your investment delivers precision performance for EVA molding, laminated wood processing, and electrical insulation applications. Gaomi Hongxiang's expertise in CNC equipment manufacturing and commitment to international standards positions us as your ideal partner for bulk orders and custom OEM solutions. Contact our engineering team today to discuss your specific requirements and receive a detailed technical proposal tailored to your production needs.

NAVIGATION

MESSAGE

Request A Quote?