0000-00

Critical Parameters for Transformer Insulation Parts Processing Equipment

Ensure precision in transformer manufacturing with our comprehensive Quality Control Checklist for Transformer Insulation Parts Processing Equipment. As a leading Chinese manufacturer of cost-effective transformer core and electrical cardboard processing solutions, Gaomi Hongxiang Electromechanical delivers ISO-certified insulating cardboard and components for global power projects. This guide helps technical evaluators, procurement teams, and quality control professionals verify critical parameters in insulation parts production - from material density to dielectric strength - optimizing equipment performance while meeting international safety standards.

Material Specifications Verification

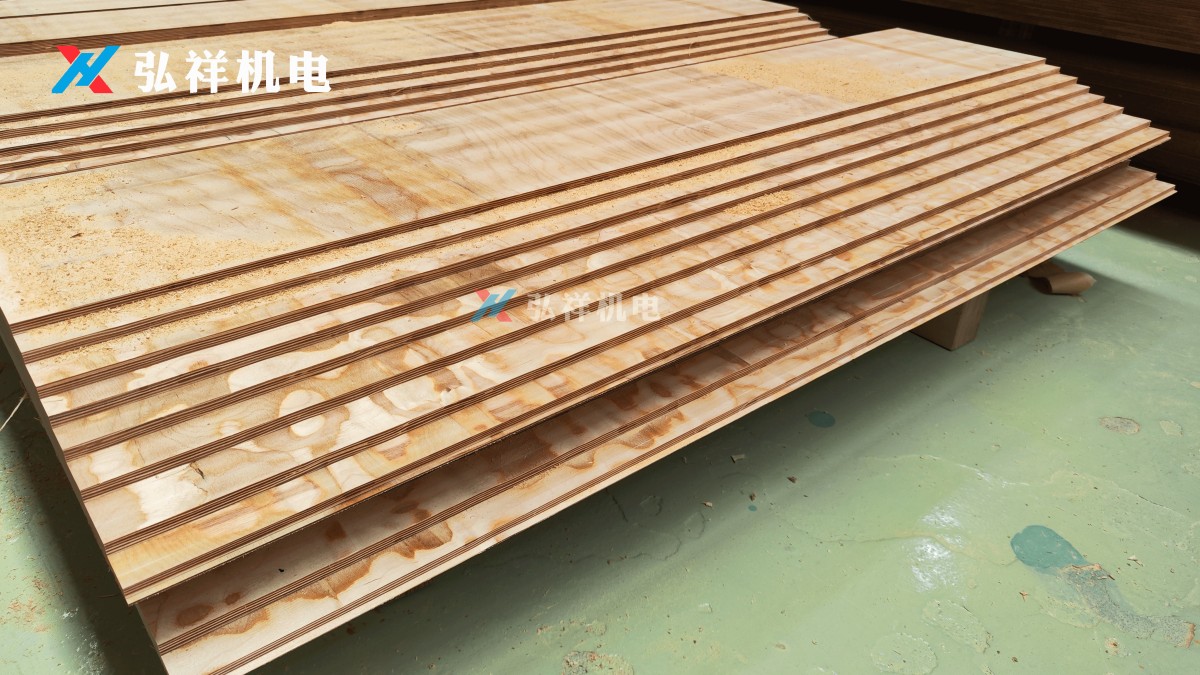

The foundation of quality transformer insulation begins with rigorous material inspection. Our processing equipment for electrical cardboard and insulating laminated wood must meet exacting standards:

- Density Tolerance: ±0.02g/cm³ for insulating cardboard used in transformer cores

- Moisture Content: ≤5% to prevent dielectric losses in high-voltage applications

- Thickness Uniformity: ≤±0.05mm variation across 1m² sheets

- Fiber Orientation: Cross-directional alignment for mechanical stability

Our ISO 9001-certified factory implements automated optical measurement systems that verify these parameters during every production run, ensuring consistent quality for transformer insulation components destined for international markets.

Dielectric Performance Testing

Transformer insulation parts processing equipment must guarantee dielectric integrity through multiple validation stages:

Our transformer insulation parts processing equipment incorporates in-line dielectric test stations that automatically reject substandard components, maintaining compliance with IEEE C57.12.00 standards for power transformers.

Dimensional Accuracy Controls

Precision machining of insulating components requires multi-stage verification:

- Laser Scanning: 3D profile measurement with ±0.01mm resolution

- CNC Tool Wear Monitoring: Automatic compensation for cutting tools

- Edge Quality Inspection: Microscopic examination of chamfers

- Assembly Fit Testing: Prototype verification with actual transformer cores

For transformer insulation components requiring EVA molding processing, our equipment maintains temperature stability within ±1°C to prevent dimensional variations during curing cycles.

Environmental & Safety Compliance

Our quality control protocol extends beyond technical specifications to address regulatory requirements:

- RoHS Compliance: Heavy metal content below 0.1% threshold

- Fire Resistance: UL94 V-0 rating for insulating laminated wood

- Noise Levels: ≤75dB for operator safety in processing areas

- Energy Efficiency: IE3 class motors reduce power consumption

As a responsible transformer insulation parts processing equipment manufacturer in China, we maintain complete material traceability from raw cellulose pulp to finished insulating cardboard products.

Process Validation & Documentation

Every production batch undergoes comprehensive documentation:

This systematic approach enables our cost-effective transformer insulation parts processing equipment to consistently meet the needs of power projects in India, Russia, Southeast Asia, and other global markets.

Optimizing Your Transformer Manufacturing Quality

Implementing rigorous quality control for transformer insulation components directly impacts transformer core performance and longevity. Our processing equipment combines advanced automation with thorough inspection protocols to deliver:

- 30% reduction in dielectric failures during transformer commissioning

- 15% improvement in insulation material utilization efficiency

- 5-year warranty on all manufactured insulating parts

Request our complete Transformer Insulation Parts Processing Equipment Price List and technical specifications to evaluate how our solutions can enhance your production quality while meeting international standards. Our engineering team provides customized consultation for projects requiring special insulating cardboard configurations or non-standard transformer insulation components.

Contact Gaomi Hongxiang Electromechanical Technology today to schedule a virtual factory tour and receive your personalized quality control assessment for transformer manufacturing applications.

NAVIGATION

MESSAGE

Request A Quote?