0000-00

Article selected from "Insulation Materials"

As China's railway transportation continues to develop towards high-speed and heavy-load operations, the thermal resistance requirements for traction motor insulation systems have been progressively elevated. Currently, the highest thermal resistance rating is achieved by silicone-based insulation systems. Although domestic technological breakthroughs in silicone-impregnated resins have been realized and put into practical use, the silicone glass cloth-reinforced aramid fiber mica tapes for higher-speed traction motors still rely on imports, which hinders the localization of China's high-speed locomotive insulation systems.

In recent years, multiple domestic enterprises and research institutions have conducted localization studies on silicone-impregnated resins and mica tapes, with some achievements demonstrating promising results in practical applications. However, domestically produced silicone glass cloth-reinforced aramid fiber mica tapes still exhibit gaps compared to imported products in terms of processability, insulation structural performance, and environmental reliability. This paper focuses on addressing these issues by investigating the compatibility between adhesives and impregnated resins in mica tapes. By introducing reactive functional groups that interact with impregnated resins into the adhesive, the study aims to enhance the structural integrity and electrical performance of insulation systems, thereby promoting the localized application of this material.

Automatic Four-Side Chamfering Machine

This machine is designed for simultaneous chamfering of all four longitudinal edges on workpieces such as laminated wood, laminated paperboard, spacers, and wooden semi-finished products.

This study uses alkali-free glass fiber cloth and aramid fiber mica paper as the main raw materials. Self-made silicone adhesive and commercially available silicone adhesive are used to prepare silicone glass cloth reinforced aramid fiber mica tape, and the performance is compared with an imported similar product.

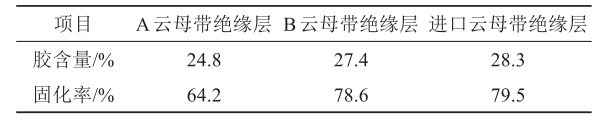

By simulating the preparation of wire rods, three types of mica tapes were wrapped and impregnated with the same imported silicone impregnated resin under the same process conditions. After baking and curing, their electrical properties, curing rate and environmental reliability were systematically evaluated. The test contents include adhesive curing rate, basic performance of mica tape, normal and hot dielectric loss factors, breakdown voltage, main insulation layer curing rate and multi-environmental factor durability test.

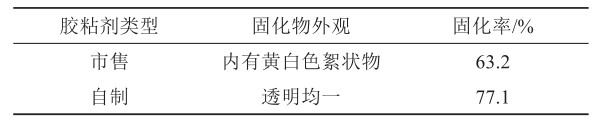

1 Adhesive Cure Rate and Compatibility

After the commercially available silicone adhesive and impregnating resin are cured, yellowish-white floc appears, with a curing rate of only 63.2%, indicating poor compatibility. The self-made adhesive is transparent and uniform after curing, with a curing rate of 77.1%, meeting the technical requirement of ≥75%. Analysis suggests that the vinyl and phenyl structures introduced into the self-made adhesive enhance the reactivity and compatibility with the impregnating resin, forming a homogeneous whole.

Table 1 Appearance and curing rate of cured products of silicone adhesive and impregnated resin

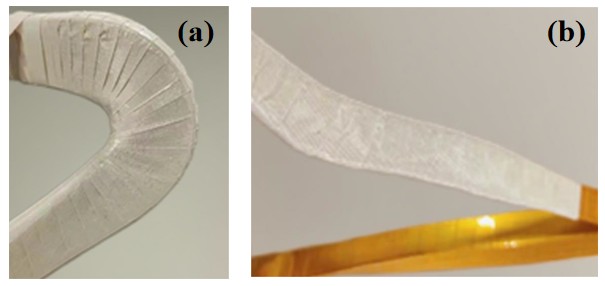

2 Adhesive processability

The study optimized the adhesive formula through orthogonal experiments and determined that the optimal process parameters were: vinyl content 5%, catalyst dosage 2%, and reaction time 2 hours. The mica tape prepared under these conditions has excellent adhesion and softness, no back-adhesion phenomenon, and good wrapping processability.

Figure 1 Wrap appearance verification (a) Appearance of the end of the wrap coil; (b) Appearance of the wrap lead

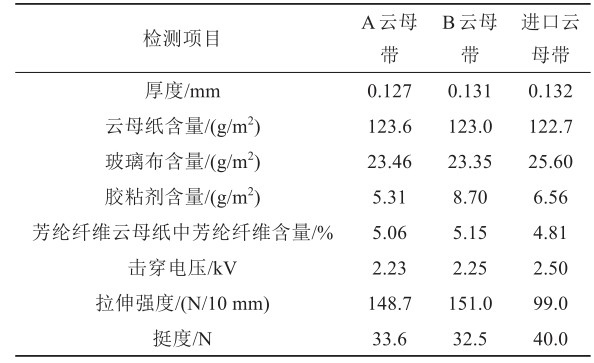

3 Basic properties of mica tape

Table 2 Test results of silicone glass cloth reinforced aramid fiber mica tape

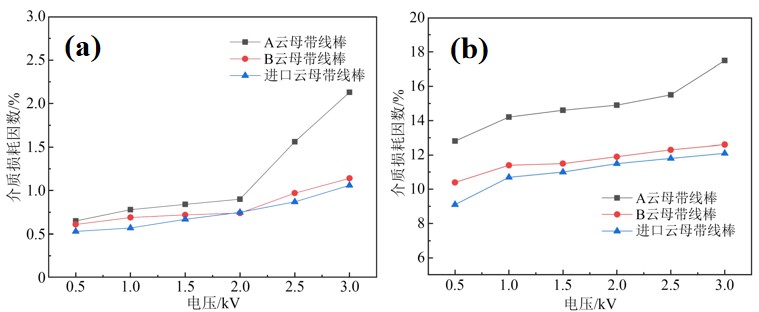

Dielectric Loss Factor in Normal Conditions: At 3kV high voltage, the dielectric loss factor of A mica tape rod shows a significant increase, while B mica tape rod performs comparable to imported products, indicating excellent insulation integrity and minimal internal air gaps.

Dielectric Loss Factor in Hot Conditions: At 200℃, B mica tape rod matches imported products in performance, further validating the adhesive's compatibility with the resin.

Breakdown Voltage: B mica tape rod's breakdown voltage is on par with imported products but higher than A mica tape, demonstrating superior insulation strength and integrity.

Figure 2 Dielectric loss factors of (a) normal and (b) thermal states at different voltages

Figure 3 Bar breakdown voltage

Through systematic research on the wrapping process, electrical performance and environmental reliability of self-made silicone glass cloth reinforced aramid fiber mica tape, the following conclusions are drawn:

(1) The adhesive used in homemade mica tape has good compatibility with the impregnating resin, and the curing rate meets the technical requirements;

(2) The self-made mica tape wrapping process is excellent, and the tensile strength and stiffness are better than imported products;

(3) The self-made mica tape is equivalent to imported products in terms of electrical properties such as normal and hot dielectric loss factors and breakdown voltage. It has good environmental reliability and can replace imported products for the insulation treatment of high-speed traction motors.

Gao Mi Hong Xiang Electromechanical Technology Co., Ltd. is a private enterprise specializing in global customer services. The company provides three core product lines: power transformer assembly manufacturing, electrical insulation paperboard, insulation laminated wood, and insulation component processing, along with EVA molding services. It also supports AI-powered specialized machine manufacturing. As a comprehensive provider, it integrates R&D design, production, sales, installation, training, and after-sales services. Its products are widely sold domestically and exported to Southeast Asia, South America, India, Pakistan, Russia, and other regions.

NAVIGATION

MESSAGE

Request A Quote?