0000-00

Understanding the Role of Insulating Cardboard in Transformer Efficiency

Discover the critical role of insulating cardboard in transformer performance with our technical breakdown. As a leading Transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang Electromechanical delivers high-quality electrical cardboard solutions for transformer cores and insulation components. This guide explores specifications, cost-effective options, and key considerations for technical evaluators, procurement specialists, and project managers seeking reliable Transformer insulation components.

Key Material Properties of Transformer Insulating Cardboard

High-performance insulating cardboard for transformers must meet stringent electrical and mechanical requirements. The material's dielectric strength typically ranges between 10-30 kV/mm, with moisture absorption rates below 5% to maintain insulation integrity. Our electrical cardboard solutions at Gaomi Hongxiang feature:

- Thermal stability up to 105°C continuous operation

- Compressive strength exceeding 50 MPa for transformer core applications

- Customizable thickness from 0.5mm to 3.0mm

- Low partial discharge characteristics (<10 pC)

- Halogen-free composition meeting IEC 61212 standards

These specifications ensure reliable performance in various transformer designs, from small distribution units to large power transformers. The material's anisotropic properties are particularly crucial for directional stress management in transformer insulation components.

Manufacturing Process and Quality Control

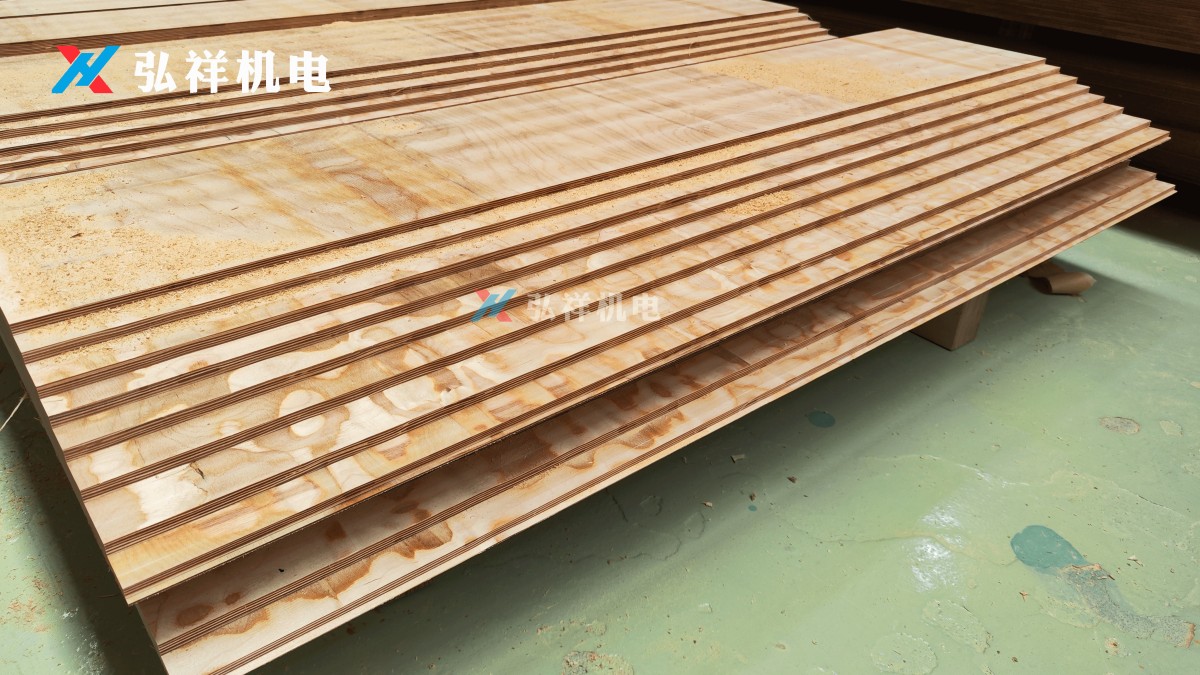

As a specialized Transformer insulation parts processing equipment manufacturer in China, we implement rigorous production protocols. Our manufacturing process involves precision calendering of cellulose fibers with controlled resin impregnation, achieving uniform density throughout the material. Key stages include:

Our quality assurance program includes 100% dimensional verification and batch sampling for dielectric testing, ensuring every sheet of insulating cardboard meets or exceeds IEEE Std C57.12.91 requirements for transformer insulation components.

Cost-Effective Solutions for Transformer Manufacturers

For procurement specialists evaluating Transformer insulation parts processing equipment price lists, several factors influence total cost of ownership:

- Material Efficiency: Our optimized cutting patterns reduce waste by 15-20% compared to standard solutions

- Operational Longevity: High-density electrical cardboard extends maintenance intervals by 30-40%

- Energy Savings: Improved thermal properties can reduce transformer load losses by 2-3%

- Customization Options: Pre-cut shapes and pre-punched designs minimize secondary processing costs

We offer volume-based pricing tiers and just-in-time delivery options to help project managers optimize their transformer production budgets without compromising on insulation quality.

Technical Selection Guide for Different Transformer Types

Selecting the appropriate insulating cardboard requires understanding specific transformer applications:

Distribution Transformers (≤10 MVA)

Standard grade electrical cardboard (1.0-1.5mm) with medium density provides sufficient mechanical support and insulation for these smaller units. Our cost-effective transformer insulation parts processing equipment can produce these components with fast turnaround times.

Power Transformers (10-100 MVA)

High-density (≥1.2 g/cm³) insulating cardboard with enhanced oil resistance is recommended. These transformer cores require materials that can withstand higher electromagnetic forces and prolonged thermal stress.

Specialty Transformers (Traction, Furnace, HVDC)

Custom formulations with added thermal stabilizers or vibration-resistant properties may be necessary. As a leading Transformer insulation components supplier, we can engineer materials to meet these unique requirements.

Industry Standards and Compliance

Our insulating cardboard products comply with major international standards essential for global transformer manufacturers:

- IEC 60641-3: Pressboard and presspaper for electrical purposes

- ASTM D202: Standard test methods for dry-type insulating materials

- NEMA LI 1: Industrial laminated thermosetting products

- GB/T 19264: Chinese national standard for transformer insulation materials

For projects requiring specific certifications (UL, CSA, etc.), we provide complete documentation packages including material safety data sheets and test reports.

Conclusion and Next Steps

Selecting the right insulating cardboard for transformers requires careful consideration of electrical, mechanical, and thermal properties. As a trusted Transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang Electromechanical Technology Co., Ltd. provides technical expertise and reliable materials for transformer cores and insulation components across all voltage classes.

Our cost-effective transformer insulation parts processing equipment delivers consistent quality while helping manufacturers control production costs. With extensive experience supplying both domestic and international markets (including Southeast Asia, South America, and Europe), we understand the diverse requirements of global transformer production.

For detailed technical specifications or to discuss your specific insulating cardboard requirements, contact our engineering team today. We offer comprehensive support from material selection through production implementation, ensuring optimal performance for your transformer insulation components.

NAVIGATION

MESSAGE

Request A Quote?