0000-00

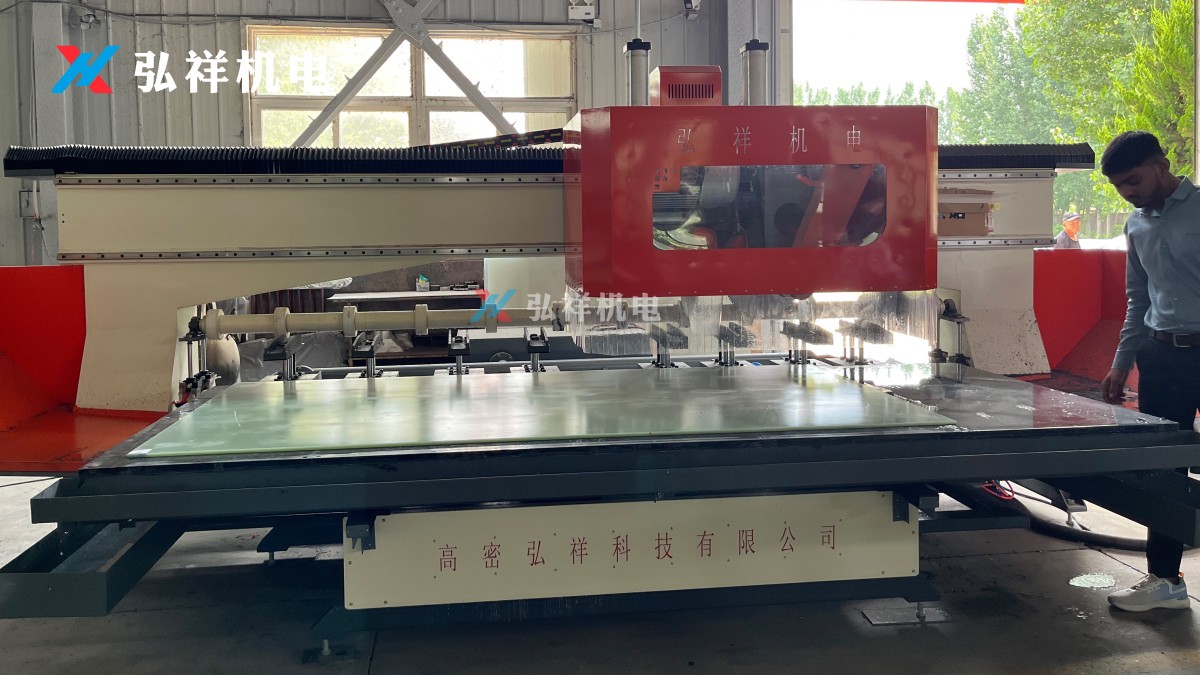

Discover precision-engineered transformer insulation parts processing equipment for bulk orders, EVA molding, and laminated wood applications. As a leading Chinese manufacturer, Gaomi Hongxiang Electromechanical Technology Co., Ltd. offers OEM services and custom CNC solutions for electrical insulation components. Our specialized machinery serves global clients across power transformer manufacturing, AI equipment production, and electrical insulation systems. Explore reliable sourcing options for high-performance processing equipment that meets international standards and diverse industrial requirements.

Core Components of Transformer Insulation Parts Processing Equipment

The manufacturing of transformer insulation parts requires specialized equipment designed to handle materials like electrical insulating cardboard, laminated wood, and EVA composites with micron-level precision. Modern CNC transformer insulation parts processing equipment integrates several critical subsystems to achieve this:

- Multi-axis CNC Routing Systems: 5-7 axis configurations capable of complex contouring for insulation components with tolerances within ±0.05mm

- Thermoforming Modules: Computer-controlled heating elements (50-300°C range) for EVA molding processing with uniform temperature distribution

- Lamination Presses: Hydraulic or servo-electric systems generating 5-20 tons of pressure for bonding insulating laminated wood

- Laser Measurement Systems: In-process quality verification ensuring dimensional accuracy per IEC 60641 standards

- Dust Extraction: Industrial HEPA filtration maintaining Class 1000 cleanroom conditions during dry machining

For bulk order production, these systems are typically configured in cellular manufacturing layouts with automated material handling between stations. The integration of Industry 4.0 protocols allows real-time monitoring of production metrics - a critical feature for OEM service providers managing global supply chains.

Advanced Processing Techniques for Electrical Insulation Components

Contemporary transformer insulation parts processing equipment employs several proprietary techniques to address material-specific challenges:

EVA Molding Processing Innovations

Our EVA molding processing solutions feature dynamic temperature zoning that adapts to material thickness variations (0.5-15mm) during the curing cycle. This prevents internal stresses that could compromise dielectric strength in the finished insulation parts. The equipment's closed-loop pressure control maintains optimal compression force throughout the 8-12 minute curing period, critical for achieving consistent density across large panels.

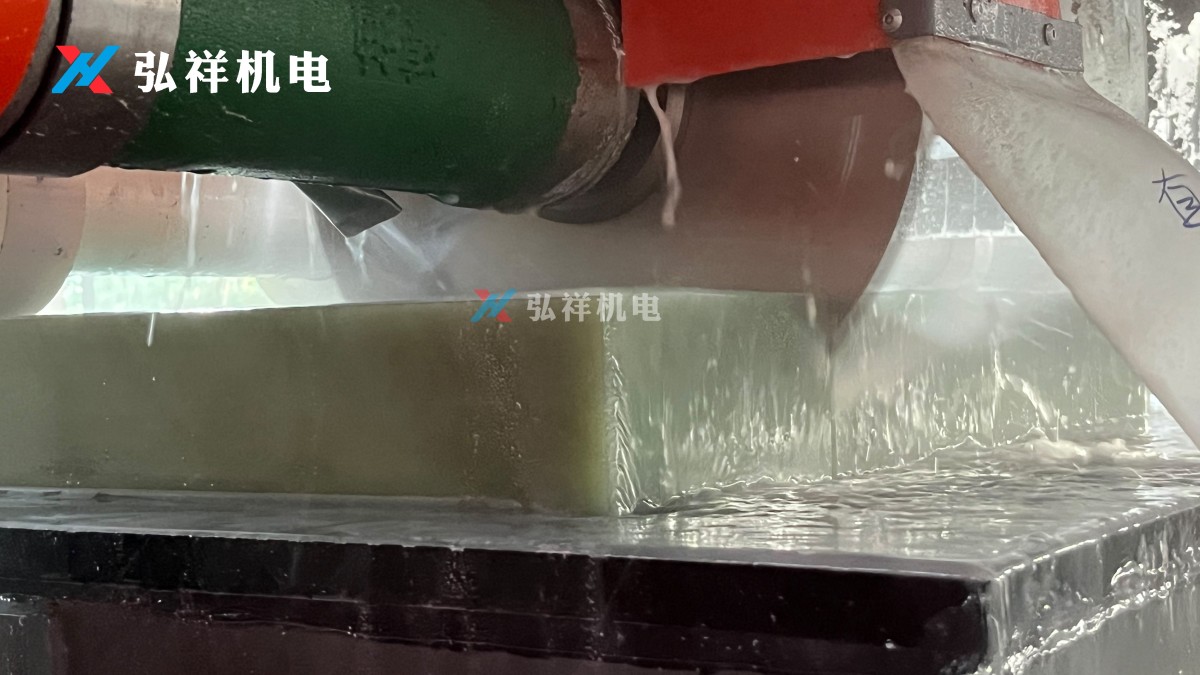

Laminated Wood Precision Machining

For insulating laminated wood components, our CNC transformer insulation parts processing equipment utilizes vibration-damped spindles (12,000-24,000 RPM) with specialized tool geometries. This prevents delamination during high-speed machining of complex profiles like winding spacers and clamping rings. The systems incorporate moisture compensation algorithms that automatically adjust cutting parameters based on real-time material moisture content (3-8% range) readings from embedded sensors.

Customization Capabilities for Diverse Industrial Requirements

As a premier transformer insulation parts processing equipment manufacturer in China, we provide extensive customization options:

For specialized applications like ultra-high voltage (UHV) transformer insulation, we develop custom transformer insulation parts processing equipment with enhanced capabilities. These include cryogenic machining options for composite materials and cleanroom-compatible configurations meeting ISO Class 5 standards.

Global Sourcing Considerations for Processing Equipment

When sourcing transformer insulation parts processing equipment, international buyers should evaluate several critical factors:

- Compliance Certifications: Equipment should meet CE, UL, or GB standards depending on target markets

- Material Compatibility: Verify machine capability with your specific insulation materials (NOMEX®, pressboard, etc.)

- Production Capacity: Assess throughput rates (parts/hour) against your projected demand

- After-Sales Support: Availability of local service technicians and spare parts inventory

- Energy Efficiency: Compare power consumption metrics (kWh/kg of processed material)

Our factory provides comprehensive documentation packages including FAT (Factory Acceptance Test) protocols, risk assessments per ISO 12100, and detailed maintenance manuals - essential for project managers overseeing equipment commissioning.

Conclusion: Partnering for Precision Insulation Manufacturing

In today's competitive power equipment market, transformer manufacturers require processing solutions that combine precision engineering with operational flexibility. Our transformer insulation parts processing equipment delivers this through:

- Advanced CNC capabilities for complex electrical insulation components

- Custom configurations for EVA molding, laminated wood, and composite materials

- Scalable production systems supporting both prototype development and bulk orders

- Comprehensive OEM service with full documentation and training support

Contact our engineering team today to discuss your specific transformer insulation parts processing requirements. We'll provide detailed equipment specifications, application case studies, and customized sourcing solutions tailored to your operational needs.

NAVIGATION

MESSAGE

Request A Quote?