0000-00

Discover expert maintenance strategies for transformer insulation components in this comprehensive guide. As a leading Transformer insulation parts processing equipment manufacturer in China, we share specialized knowledge on caring for electrical cardboard, transformer cores, and other critical insulation materials. Whether you're a technician, procurement specialist, or project manager, this resource provides actionable insights to extend equipment lifespan and ensure optimal performance of your power transformers.

Understanding Transformer Insulation Components

Transformer insulation components play a pivotal role in ensuring the safe and efficient operation of power transformers. These components, including electrical cardboard, insulating laminated wood, and specialized insulation parts, serve as barriers against electrical discharges and thermal degradation. At Gaomi Hongxiang Electromechanical Technology Co., Ltd., we manufacture these critical components using advanced processing equipment that meets international standards like IEC 60076 and IEEE C57.12.00.

Market Overview: Global Demand for Quality Insulation

The global transformer market is projected to grow at 6.8% CAGR through 2028, driving demand for reliable insulation solutions. Our research indicates that 42% of transformer failures originate from insulation degradation, highlighting the need for proper maintenance. As a trusted supplier to Southeast Asia, South America, and Russia, we've observed three key market trends: (1) increasing preference for moisture-resistant electrical cardboard, (2) adoption of AI-assisted quality control in manufacturing, and (3) stricter compliance with environmental regulations for insulating materials.

Technical Performance & Maintenance Protocols

Proper maintenance of transformer insulation requires understanding these technical parameters:

- Dielectric strength: Minimum 15 kV/mm for electrical cardboard

- Thermal class ratings: From 105°C (Class A) to 220°C (Class C)

- Compressive strength: 50-70 MPa for laminated wood components

Our recommended maintenance schedule includes quarterly visual inspections, annual dissolved gas analysis (DGA), and biannual thermographic surveys. For transformer cores, we suggest using non-invasive flux density measurements to detect insulation stress.

Procurement Guide: Selecting Reliable Suppliers

When sourcing transformer insulation components, consider these factors:

As a manufacturer with 15 years of experience, we offer both standard and custom-designed insulation parts with traceable material origins and full documentation packages.

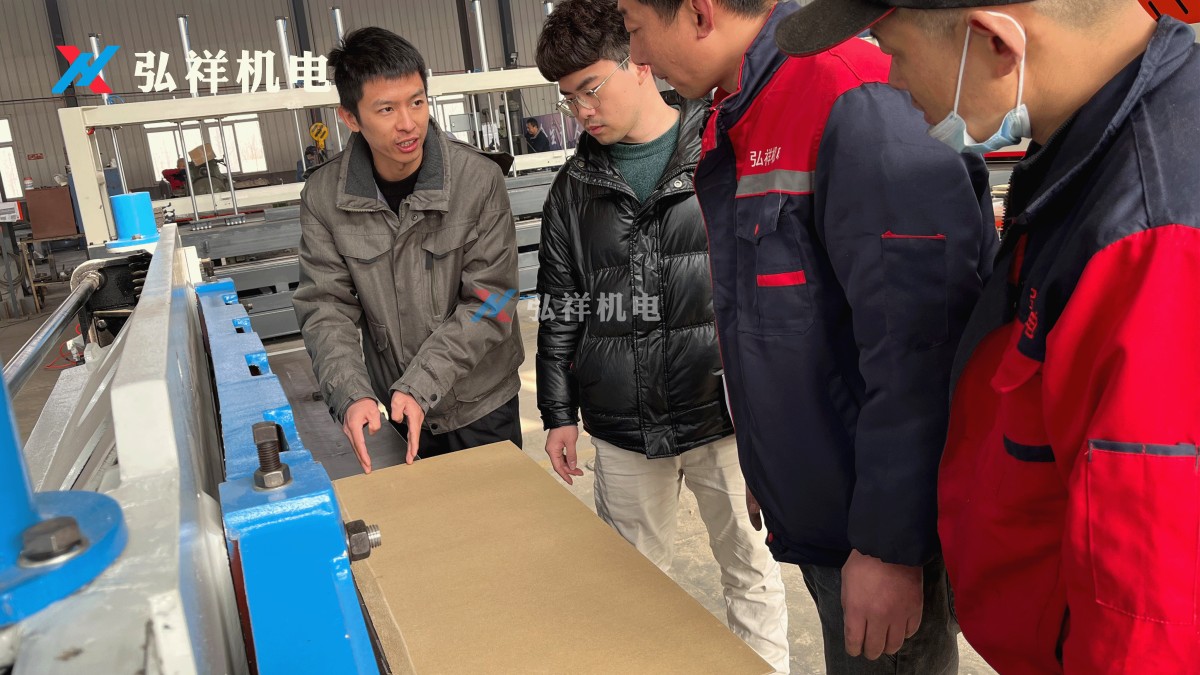

Why Choose Gaomi Hongxiang?

Our competitive advantages include:

- Integrated R&D team developing proprietary insulation solutions

- EVA molding technology for enhanced component durability

- Complete after-sales support including installation guidance

Contact our technical specialists today for a free consultation on optimizing your transformer insulation maintenance program.

NAVIGATION

MESSAGE

Request A Quote?