0000-00

Understanding Transformer Insulation Parts Processing Equipment

Transformer insulation parts processing equipment plays a critical role in manufacturing high-quality transformer cores and insulation components. These machines are designed to handle specialized materials like electrical insulating cardboard and laminated wood with precision. Proper maintenance ensures consistent output quality while minimizing downtime - a crucial factor for manufacturers serving global markets from Southeast Asia to South America.

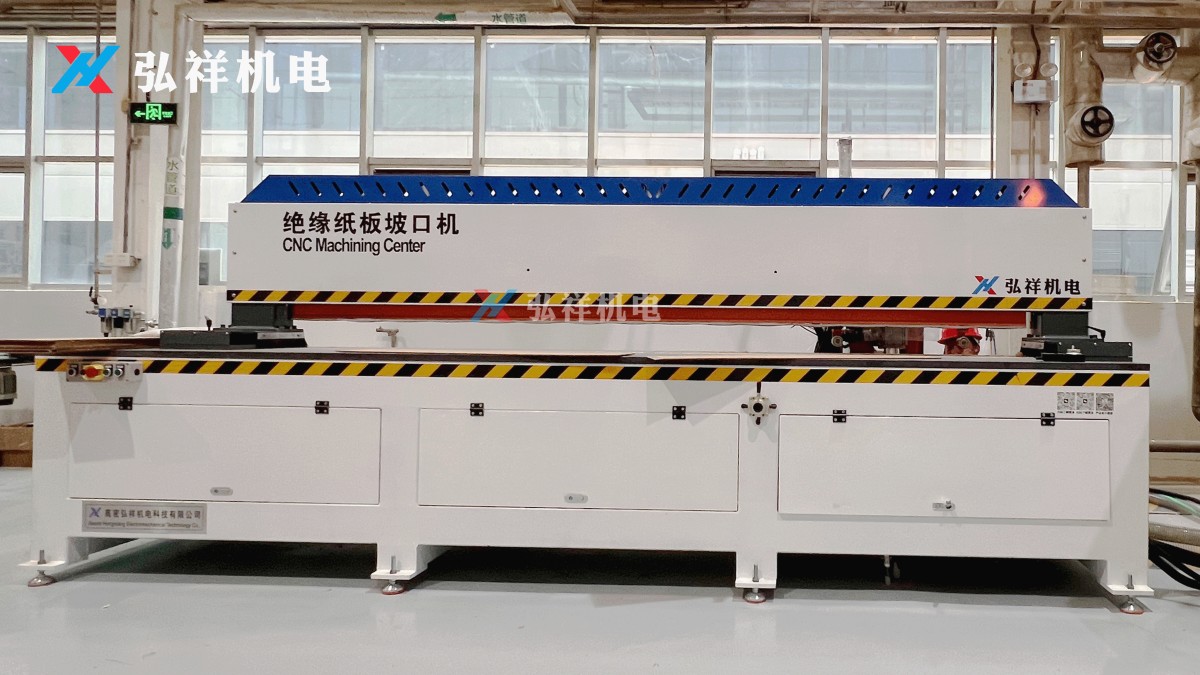

Bevel Milling Machine

This specialized CNC machine is designed for beveling the edges of insulating materials like electrical pressboard, insulating paper, and laminated board.

Essential Maintenance Practices

Regular maintenance of transformer insulation processing equipment involves several key aspects:

- Daily cleaning to prevent material buildup that could affect precision

- Lubrication schedules following manufacturer specifications

- Calibration checks for cutting and forming accuracy

- Electrical system inspections to prevent failures

- Wear part replacement before critical failure occurs

Technical Performance & Optimization

Modern transformer insulation parts processing equipment incorporates advanced technologies to meet stringent industry standards. Key performance indicators include:

Regular maintenance directly affects these parameters, making it essential for quality control personnel and operations managers.Industry Trends & Future Outlook

The transformer manufacturing industry is evolving with:

- Increased automation in processing equipment

- Integration of IoT for predictive maintenance

- Development of eco-friendly insulation materials

- Demand for custom transformer insulation parts processing equipment

Why Choose Gaomi Hongxiang

With extensive experience as a Transformer insulation parts processing equipment manufacturer in China, we offer:

- Comprehensive maintenance training programs

- Global spare parts availability

- Customized solutions for transformer core production

- Advanced equipment like our Automatic four-sided chamfering machine for precision processing

Contact Our Experts

For specialized maintenance advice or equipment inquiries, contact Gaomi Hongxiang's technical team. We provide end-to-end support from equipment selection to after-sales service, ensuring your transformer insulation parts processing operations achieve maximum efficiency and longevity.

NAVIGATION

MESSAGE

Request A Quote?