0000-00

Discover the critical specifications for transformer core manufacturing that ensure optimal performance. As a leading transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang Electromechanical provides premium electrical cardboard and transformer insulation components. Our expertise in processing insulating laminated wood and EVA molding delivers reliable solutions for power transformers worldwide. Whether you're a procurement specialist or technical evaluator, learn how our precision-engineered transformer core solutions enhance efficiency and durability across industries.

Understanding Transformer Core Manufacturing

The transformer core is the heart of any power transformer, responsible for efficient energy transfer and minimizing losses. At Gaomi Hongxiang Electromechanical, we specialize in manufacturing transformer cores that meet the highest industry standards. Our process begins with selecting the finest grain-oriented electrical steel, which is then precisely cut and stacked to create cores with optimal magnetic properties. The quality of transformer cores directly impacts energy efficiency, with high-performance cores reducing no-load losses by up to 30% compared to standard designs. Our manufacturing facilities in China utilize advanced laser cutting and automated stacking systems to ensure dimensional accuracy within ±0.1mm, a crucial factor for transformer performance.

Technical Specifications for Optimal Performance

When evaluating transformer core specifications, several critical factors must be considered. The core loss (measured in W/kg at specific frequencies and flux densities) is perhaps the most important parameter, directly affecting transformer efficiency. Our electrical cardboard and insulating laminated wood components are engineered to withstand temperatures up to 180°C while maintaining excellent dielectric strength. The table below outlines key specifications for our transformer insulation components:

Global Market Trends in Transformer Core Manufacturing

The global transformer market is projected to grow at a CAGR of 6.8% from 2023 to 2030, driven by increasing energy demand and grid modernization initiatives. As a China-based transformer insulation parts processing equipment manufacturer with international reach, we've observed several key trends. First, there's growing demand for amorphous metal cores in distribution transformers, offering 70-80% lower core losses than conventional silicon steel. Second, the shift toward renewable energy integration requires transformers with enhanced thermal performance, which our insulating laminated wood components are particularly suited for. Third, digitalization is transforming quality control processes, and we've responded by implementing AI-powered inspection systems that detect defects with 99.7% accuracy.

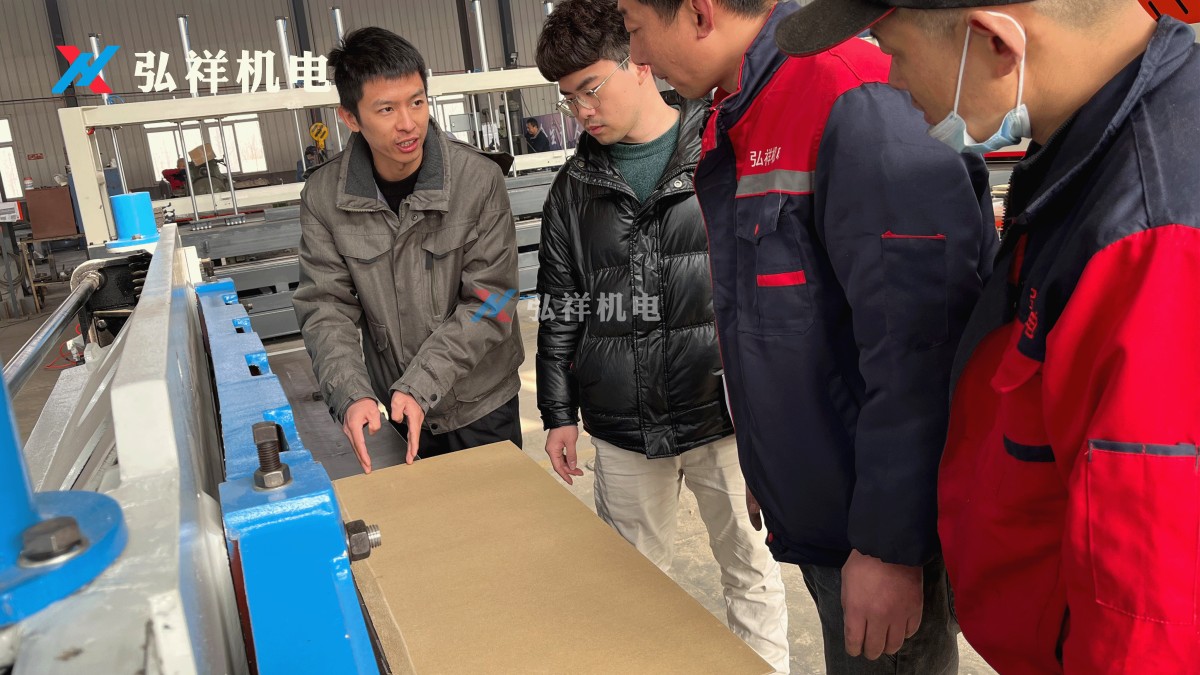

Why Choose Gaomi Hongxiang Electromechanical?

With over 15 years of experience as a transformer insulation parts processing equipment manufacturer, we offer unparalleled expertise in electrical cardboard and transformer insulation components. Our competitive advantages include:

- ISO 9001-certified manufacturing facilities with strict quality control

- Custom solutions for special transformer designs, including AI applications

- Complete in-house capabilities from material processing to final assembly

- Global supply chain with exports to 30+ countries

- Technical support team with 10+ years average industry experience

Contact Our Transformer Core Experts Today

Whether you're sourcing transformer insulation components for a utility-scale project or need specialized electrical cardboard for your manufacturing process, our team is ready to assist. As a trusted transformer insulation parts processing equipment manufacturer in China, we combine technical excellence with responsive customer service. Contact us today to discuss your specific requirements and discover how our solutions can optimize your transformer performance while reducing total cost of ownership.

NAVIGATION

MESSAGE

Request A Quote?