0000-00

Transformer insulation failure can lead to costly downtime and safety hazards in power systems. As a leading transformer insulation parts processing equipment manufacturer in China, we analyze common causes of transformer core and electrical cardboard degradation. This guide provides actionable prevention methods for technical evaluators, procurement specialists, and maintenance teams to enhance transformer reliability and lifespan.

Understanding Transformer Insulation Failure

Transformer insulation components are critical for maintaining electrical integrity and preventing short circuits. The transformer core and electrical cardboard work together to isolate conductive parts and manage heat dissipation. When these components degrade, it can result in partial discharges, thermal runaway, or complete system failure. Understanding the root causes is the first step toward effective prevention.

Common Causes of Insulation Failure

Several factors contribute to the deterioration of transformer insulation parts. Moisture ingress is a primary culprit, as it reduces the dielectric strength of insulating materials. Contaminants such as dust, oil, or chemical residues can also accelerate aging. Thermal stress from overload conditions or poor cooling leads to material breakdown over time. Additionally, mechanical vibrations and improper handling during installation can cause physical damage to the insulation.

Prevention Methods for Long-Term Reliability

To mitigate insulation failure, regular maintenance and proper material selection are essential. Using high-quality electrical cardboard and insulating laminated wood from trusted suppliers like Gaomi Hongxiang ensures better performance. Implementing moisture barriers and desiccant breathers can protect against humidity. Routine inspections, including dissolved gas analysis (DGA) and partial discharge testing, help detect early signs of degradation. For procurement teams, choosing transformer insulation parts processing equipment with advanced manufacturing standards is crucial for durability.

Market Overview: The Importance of Quality Insulation

The global demand for reliable transformer insulation components is growing, driven by increasing energy needs and grid modernization. In regions like Southeast Asia and South America, where environmental conditions are harsh, the risk of insulation failure is higher. Gaomi Hongxiang's products, exported to these markets, are designed to withstand extreme temperatures and humidity. Our expertise in EVA molding processing and AI-driven manufacturing ensures that our insulation parts meet international standards such as IEC 60076 and IEEE C57.12.00.

Case Study: Successful Implementation in India

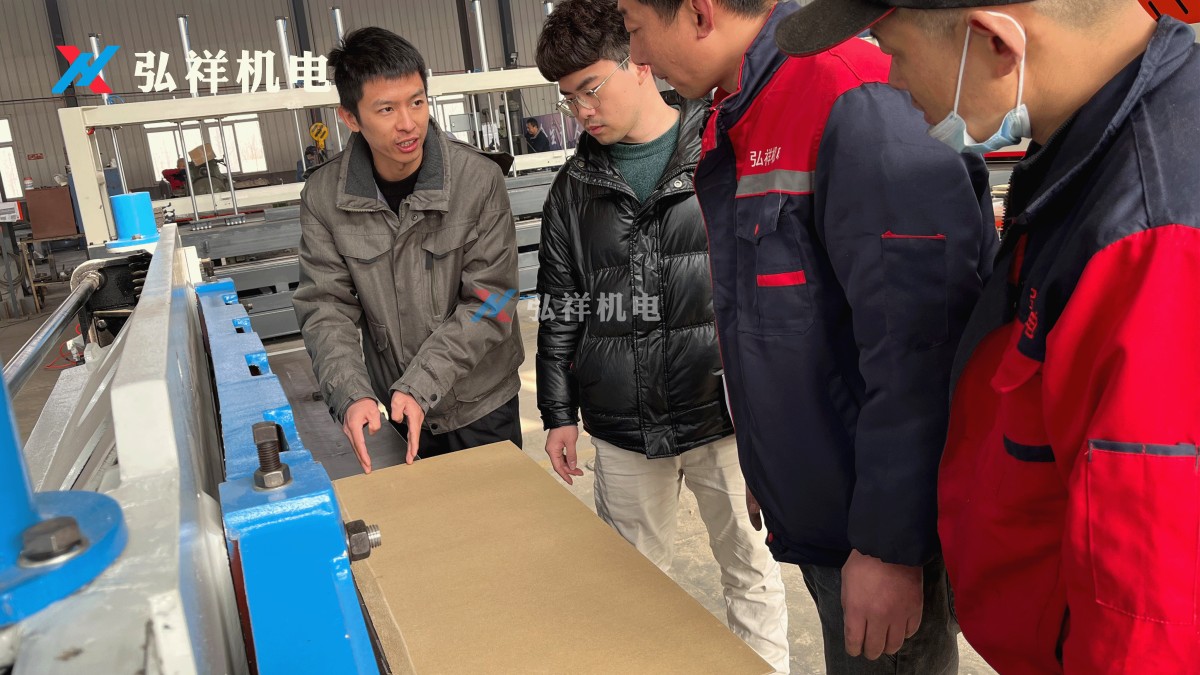

A recent project in India involved replacing outdated transformer insulation components with our advanced electrical cardboard and insulating laminated wood. The client reported a 30% reduction in downtime and improved energy efficiency. Our team provided comprehensive training for the maintenance staff, ensuring proper handling and installation. This case highlights the importance of partnering with a manufacturer that offers end-to-end solutions, from R&D to after-sales support.

FAQ: Addressing Common Concerns

Q: How often should transformer insulation be inspected?

A: We recommend annual inspections for most applications, with more frequent checks in high-stress environments.

Q: What are the signs of impending insulation failure?

A: Look for increased noise, overheating, or unusual gas levels in oil-filled transformers.

Q: Can damaged insulation be repaired, or does it need replacement?

A: Minor damage can sometimes be repaired, but significant degradation usually requires complete replacement to ensure safety.

Why Choose Gaomi Hongxiang?

With decades of experience in transformer insulation parts processing equipment manufacturing, we combine cutting-edge technology with rigorous quality control. Our products are trusted by clients in Russia, Pakistan, and beyond for their reliability and performance. From custom EVA molding to AI-integrated manufacturing, we offer solutions tailored to your specific needs. Contact us today to discuss how we can enhance your transformer's lifespan and efficiency.

NAVIGATION

MESSAGE

Request A Quote?