0000-00

Discover the ultimate cost-benefit analysis of transformer insulation parts processing equipment for industrial use. This comprehensive guide evaluates key factors when sourcing equipment for electrical cardboard and laminated wood processing. Whether you're a procurement specialist, technical evaluator, or business decision-maker, gain critical insights into comparing different brands of insulating cardboard and optimizing your transformer manufacturing operations. Learn how to balance performance, safety, and ROI for your power transformer projects.

Key Considerations When Sourcing Transformer Insulation Parts Processing Equipment

Selecting the right transformer insulation parts processing equipment requires careful evaluation of multiple technical and commercial factors. For procurement specialists and technical evaluators, understanding the relationship between equipment capabilities and transformer performance is crucial. Industrial-grade machines must handle diverse materials including electrical cardboard and laminated wood with precision, while maintaining consistent output quality. The processing equipment's ability to work with these specialized insulation materials directly impacts the transformer's dielectric strength, thermal stability, and mechanical durability. When comparing different brands, pay particular attention to the machine's tolerance levels for thickness variation in insulating materials, as even minor deviations can affect the final product's electrical properties. Production capacity requirements should be matched with the equipment's throughput rates, considering both current needs and future expansion plans. Energy efficiency metrics have become increasingly important, with modern machines offering 15-30% power savings compared to older models. The equipment's compatibility with your existing production line layout and material handling systems can significantly affect installation costs and operational efficiency. Safety certifications such as CE, UL, or specific industry standards should be verified, especially for high-voltage transformer applications. For global operations, consider the manufacturer's ability to provide localized service support and spare parts availability in your region.

Material-Specific Processing Requirements

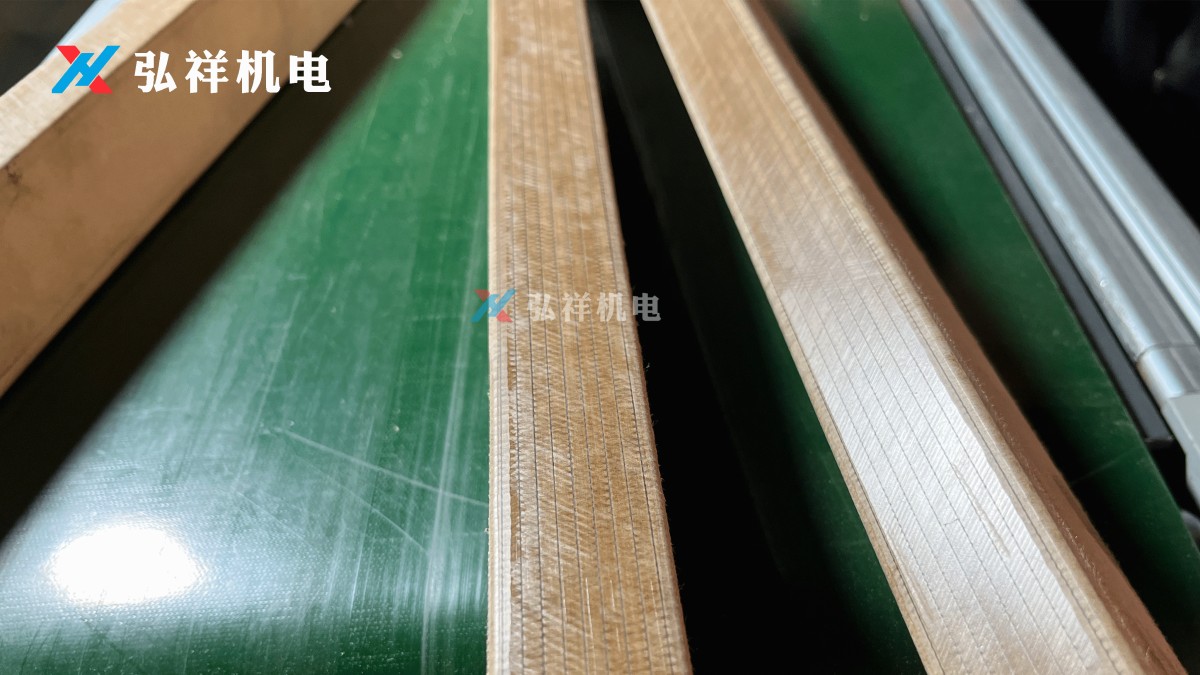

Different insulation materials demand specialized processing approaches that equipment must accommodate. Electrical cardboard processing requires precision cutting systems that can handle densities ranging from 0.8-1.2 g/cm³ without delamination or edge fraying. The equipment should maintain consistent moisture content control (typically 5-7%) during processing to prevent dimensional instability in the final product. For laminated wood insulation components, look for machines with adjustable pressure and temperature controls to achieve optimal resin penetration and curing. The processing equipment must accommodate varying wood grain orientations while maintaining tight thickness tolerances (±0.05mm). When evaluating transformer insulation parts processing equipment for laminated wood, consider the machine's ability to handle different wood species commonly used in transformer manufacturing, such as beech, birch, or maple. Modern equipment often incorporates vision systems for automatic defect detection in raw materials, reducing waste and improving yield. The cutting mechanism should be capable of producing clean edges on both cross-grain and with-grain cuts to ensure proper dielectric performance. For operations processing multiple material types, modular equipment designs allow quick changeovers between electrical cardboard and laminated wood processing configurations.

Cost-Benefit Analysis of Equipment Investment

A thorough financial evaluation of transformer insulation parts processing equipment requires looking beyond the initial purchase price. The total cost of ownership (TCO) framework should include capital expenditure, installation costs, operational expenses, maintenance requirements, and expected equipment lifespan. High-quality industrial equipment typically offers a 7-10 year service life with proper maintenance, compared to 4-6 years for lower-tier machines. Energy consumption represents 20-35% of operational costs over the equipment lifecycle, making efficiency ratings a critical comparison factor. Labor productivity gains from automated features can reduce processing costs by 15-25% through higher throughput and reduced manual handling. Consider the equipment's impact on material utilization rates - advanced nesting algorithms in modern machines can improve material yield by 8-12% compared to conventional processing methods. Downtime costs should be factored into the analysis, with reliability metrics (MTBF - mean time between failures) varying significantly between equipment classes. The availability and cost of spare parts in your region can dramatically affect long-term maintenance expenses. Some manufacturers offer performance-based service contracts that can stabilize maintenance costs over time. For financial decision-makers, calculate the payback period based on projected production volume increases, quality improvement savings, and labor efficiency gains. Return on investment (ROI) calculations should include both tangible cost savings and intangible benefits like improved product quality and customer satisfaction.

Comparative Analysis of Equipment Brands

When comparing different brands of insulating cardboard processing equipment, develop a systematic evaluation matrix that scores each vendor across multiple dimensions. Technical specifications should be compared against your specific production requirements for processing speed, accuracy, and material handling capabilities. Review the equipment's control system sophistication - modern CNC systems with adaptive machining capabilities can automatically adjust processing parameters based on material characteristics. Evaluate the manufacturer's industry experience and installed base of similar equipment in transformer manufacturing facilities. Request performance data from actual production environments rather than relying solely on laboratory test results. Compare the user interface designs across brands, as intuitive operation reduces training requirements and operator error rates. Maintenance accessibility is another critical factor - equipment designed with service points and diagnostic ports can reduce repair times by 30-50%. Consider the manufacturer's technology roadmap and commitment to future upgrades, especially important for operations planning long-term equipment utilization. For global operations, assess each brand's local service network responsiveness and spare parts inventory levels in your region. Some manufacturers offer remote diagnostic capabilities that can significantly reduce troubleshooting time for complex equipment. When comparing different brands of insulating cardboard processing solutions, don't overlook the importance of manufacturer stability and financial health, which affects long-term support availability.

Operational Efficiency and Safety Considerations

Optimizing transformer insulation parts processing operations requires balancing productivity with stringent safety requirements. Modern equipment incorporates multiple safety systems including light curtains, emergency stops, and interlocks that meet international safety standards like ISO 13849. The processing environment for electrical insulation materials often involves dust collection systems to maintain air quality and prevent combustible dust accumulation. Equipment should be evaluated for ergonomic design features that reduce operator fatigue during extended production runs. Automated material handling systems can significantly reduce manual lifting injuries while improving process consistency. For quality control personnel, look for machines with integrated measurement systems that verify critical dimensions during processing, reducing downstream inspection requirements. The equipment's noise emission levels should comply with workplace safety regulations, with many modern machines operating below 75 dB through improved vibration isolation and enclosure designs. Electrical safety is particularly important when processing materials for high-voltage transformers, requiring equipment with proper grounding and insulation monitoring systems. Consider the training requirements for operators and maintenance staff - some manufacturers offer comprehensive training programs that reduce the learning curve for new equipment. For facilities processing multiple insulation material types, equipment with quick-change tooling systems can improve operational flexibility while maintaining safety standards. Document control features, including recipe management and process parameter logging, help maintain consistent quality across production batches.

Technology Trends in Insulation Parts Processing

The transformer insulation parts processing equipment sector is experiencing several technological advancements that improve efficiency and precision. Industry 4.0 integration allows for real-time monitoring of equipment performance and predictive maintenance scheduling, reducing unplanned downtime. Advanced servo systems provide more precise control over cutting and forming operations, particularly beneficial for complex laminated wood components. Machine learning algorithms are being implemented to optimize processing parameters based on material batch variations, improving consistency in electrical cardboard products. Some manufacturers now offer augmented reality (AR) interfaces for equipment operation and maintenance, reducing training time for new technicians. The development of hybrid processing machines capable of handling multiple insulation materials in a single setup is gaining traction in the industry. Energy recovery systems that capture and reuse energy from braking and other cyclical operations can reduce power consumption by 8-12%. For operations concerned with sustainability, newer equipment models incorporate features that minimize material waste and enable recycling of processing byproducts. The integration of quality control cameras with AI-based defect detection systems has significantly improved first-pass yield rates in insulation part production. When sourcing equipment, consider these technological advancements not just for immediate benefits but also for future-proofing your investment as transformer manufacturing requirements evolve.

Conclusion and Next Steps

Selecting optimal transformer insulation parts processing equipment requires careful evaluation of technical specifications, operational requirements, and total cost of ownership. As demonstrated in this analysis, the right equipment investment can significantly enhance your transformer manufacturing capabilities while improving safety and efficiency. For procurement specialists and business decision-makers, the key lies in balancing performance requirements with financial considerations across the equipment lifecycle. Gaomi Hongxiang Electromechanical Technology Co., Ltd. brings extensive experience in power transformer component manufacturing, offering customized solutions for electrical cardboard and laminated wood processing needs. Our integrated approach combines advanced equipment technology with comprehensive support services to maximize your operational success. To explore how our transformer insulation parts processing equipment can benefit your specific application, contact our technical team for a detailed consultation. Request a personalized equipment recommendation and cost-benefit analysis tailored to your production volume, material mix, and quality requirements. For operations requiring specialized solutions, inquire about our custom machine development capabilities designed to address unique processing challenges in the transformer industry.

NAVIGATION

MESSAGE

Request A Quote?