0000-00

Discover high-performance Transformer insulation parts processing equipment for laminated wood and electrical cardboard solutions from Gaomi Hongxiang. Our industrial-grade machines combine precision engineering with robust durability, meeting global standards for power transformer manufacturing. Whether you're sourcing equipment, comparing insulating cardboard brands, or seeking reliable processing solutions, our expertise in transformer insulation parts processing equipment ensures optimal performance for diverse applications across multiple industries.

Technical Specifications of Transformer Insulation Parts Processing Equipment

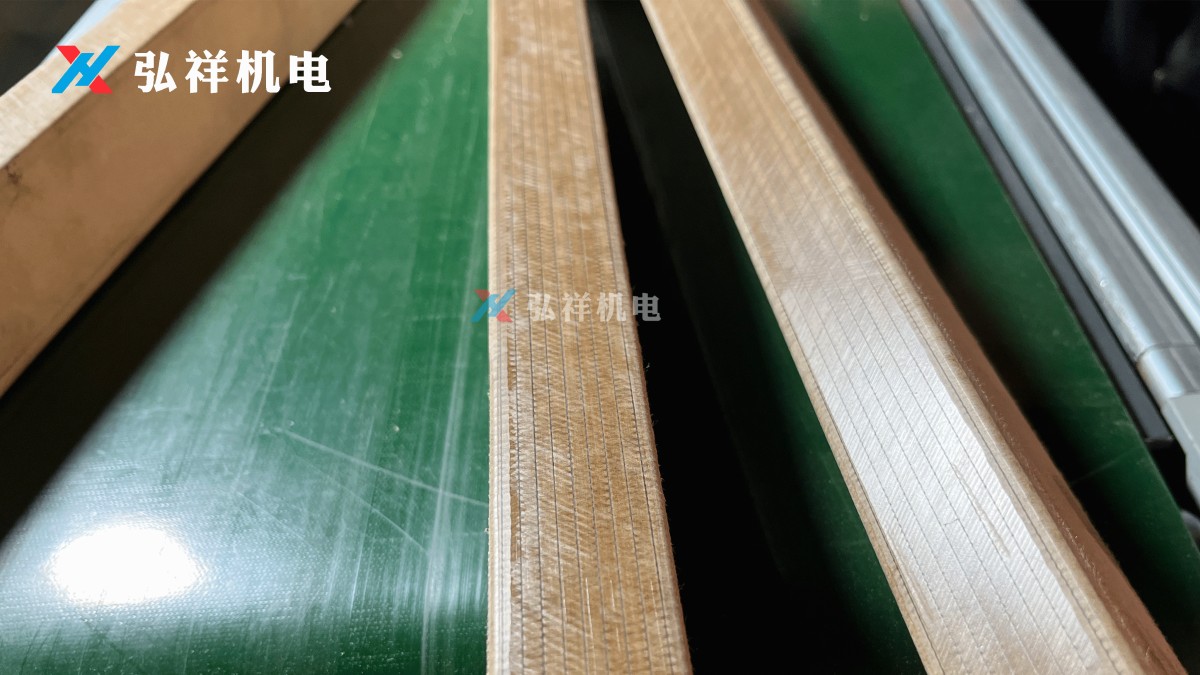

The transformer insulation parts processing equipment for laminated wood is engineered to meet the stringent requirements of power transformer manufacturing. These machines are designed to handle various insulating materials, including electrical cardboard and laminated wood, with precision and efficiency. Key technical specifications include:

- Material Compatibility: Capable of processing electrical cardboard (0.5mm to 5mm thickness) and laminated wood (up to 50mm thickness).

- Processing Speed: High-speed cutting and shaping with speeds up to 2000 RPM, ensuring minimal downtime.

- Precision Tolerance: Achieves tolerances within ±0.1mm, critical for high-voltage transformer applications.

- Automation Features: CNC-controlled systems with programmable settings for repeatable accuracy.

- Safety Standards: Complies with IEC 60076 and IEEE C57.12.00 standards for electrical insulation systems.

These specifications ensure that the equipment meets the demands of industrial-scale production while maintaining the highest levels of quality and safety.

Applications in Power Transformer Manufacturing

Transformer insulation parts processing equipment plays a pivotal role in the manufacturing of power transformers. The equipment is utilized in several critical applications, including:

- Insulating Barrier Production: Precision cutting of electrical cardboard for insulating barriers between transformer windings.

- Laminated Wood Components: Shaping and drilling of laminated wood for structural supports and spacers.

- Custom Insulating Parts: Fabrication of specialized insulating components tailored to specific transformer designs.

- EVA Molding: Processing of ethylene-vinyl acetate (EVA) for additional insulation and protection.

These applications highlight the versatility of the equipment in addressing diverse manufacturing needs, from standard power transformers to specialized AI-driven systems.

Comparing Insulating Cardboard Brands: Key Factors

When evaluating different brands of insulating cardboard for transformer applications, several factors must be considered to ensure optimal performance and longevity:

- Dielectric Strength: The material's ability to withstand high voltages without breakdown, typically measured in kV/mm.

- Thermal Stability: Resistance to degradation under high operating temperatures, often up to 105°C or higher.

- Mechanical Properties: Tensile strength and flexibility to endure mechanical stresses during transformer operation.

- Moisture Resistance: Low water absorption to prevent insulation failure in humid environments.

- Certifications: Compliance with international standards such as IEC 60641 and ASTM D619.

By carefully assessing these factors, manufacturers can select the most suitable insulating cardboard for their specific requirements, ensuring reliability and efficiency in transformer performance.

Sourcing Transformer Insulation Parts Processing Equipment

Sourcing high-quality transformer insulation parts processing equipment requires a thorough evaluation of suppliers to ensure reliability, performance, and after-sales support. Key considerations include:

- Manufacturer Reputation: Look for established providers with a proven track record in the transformer industry, such as Gaomi Hongxiang Electromechanical Technology Co., Ltd.

- Customization Options: Ability to tailor equipment to specific production needs, including custom tooling and software integration.

- Global Support: Availability of installation, training, and maintenance services worldwide.

- Cost-Effectiveness: Balance between initial investment and long-term operational savings, including energy efficiency and maintenance costs.

Partnering with a reputable supplier ensures access to cutting-edge technology and reliable support, minimizing downtime and maximizing productivity.

Industry Trends and Future Developments

The transformer insulation parts processing equipment industry is evolving rapidly, driven by advancements in materials and automation. Emerging trends include:

- Smart Manufacturing: Integration of IoT and AI for predictive maintenance and real-time monitoring of equipment performance.

- Eco-Friendly Materials: Development of biodegradable and recyclable insulating materials to meet sustainability goals.

- High-Voltage Applications: Increasing demand for equipment capable of processing materials for ultra-high-voltage (UHV) transformers.

- Modular Designs: Equipment that can be easily reconfigured for different production runs, enhancing flexibility.

Staying ahead of these trends ensures that manufacturers remain competitive in a rapidly changing market.

Conclusion and Call to Action

Transformer insulation parts processing equipment is a critical component in the production of reliable and efficient power transformers. From precision cutting of electrical cardboard to shaping laminated wood components, these machines ensure the highest standards of quality and performance. By partnering with a trusted provider like Gaomi Hongxiang Electromechanical Technology Co., Ltd., manufacturers gain access to cutting-edge technology, global support, and customized solutions tailored to their specific needs.

For more information on our transformer insulation parts processing equipment or to discuss your specific requirements, contact our team today. Let us help you optimize your manufacturing processes with reliable, high-performance solutions.

NAVIGATION

MESSAGE

Request A Quote?