0000-00

• In retrofit scenarios, thermal class matching (A-E) matters more than raw material composition.

Insulating Cardboard in Transformer Applications

Special transformer insulating cardboard serves as dielectric barrier and structural support in oil-immersed and dry-type units. Its performance directly impacts transformer lifespan through three measurable parameters: dielectric strength (typically 10-15kV/mm), thermal conductivity (0.12-0.15 W/m·K), and mechanical compression resistance (>50MPa). Industry practices show improper material selection accounts for 23% of premature transformer failures (CIGRE TB 642). Evaluation should prioritize application-specific stress factors over generic material properties.

.

Critical Questions Answered

What distinguishes transformer-grade insulating cardboard from general-purpose variants?

Transformer-specific cardboard undergoes additional impregnation processes (typically with epoxy or polyester resins) to achieve dielectric stability. The key differentiator is the standardized testing per IEC 60641-3 for oil compatibility, where acceptable fluid absorption must remain below 3% after 48-hour immersion. General-purpose materials lack these certifications.

How does moisture absorption affect performance in tropical climates?

Above 5% moisture content, cellulose-based insulation loses 30-40% dielectric strength according to IEEE Std 1523. In Southeast Asian installations, this necessitates either silica gel breathers or laminated structures with moisture barriers. Case studies from Indonesian substations show untreated cardboard degrades 2.3x faster in 80% RH environments.

What thickness tolerances are acceptable for EHV applications?

For extra-high voltage (>245kV), ANSI/IEEE C57.12.00 mandates ±0.05mm tolerance to prevent field distortion. This requires precision calendering equipment uncommon among general manufacturers. Deviations beyond 0.1mm increase corona discharge risk by 17% per millimeter variance (EPRI report {CurrentYear}).

When should polymer composites replace cellulose-based materials?

Polymer solutions become preferable when: 1) Operating temperatures exceed 105°C (Class A limit), 2) Chemical contamination risk exists (e.g., sulfur hexafluoride environments), or 3) Weight reduction is critical (composites are 40-60% lighter). However, they exhibit poorer arc resistance - a decisive factor for fault-prone installations.

How do international standards differ in testing methodologies?

IEC 60641-2 uses 50Hz AC testing while IEEE Std 1553 employs impulse waveforms. The divergence matters most for lightning-prone regions - Brazilian utilities report 12% variance in failure predictions between standards. Dual-certified materials (e.g., meeting both IEC and ANSI) typically add 15-20% cost premium.

Industry Implementation Pathways

Three prevalent approaches exist for transformer insulation:

- Pre-cut OEM kits (85% market share)

- On-site machining from bulk sheets (common in maintenance)

- Custom molded components (growing in HVDC applications)

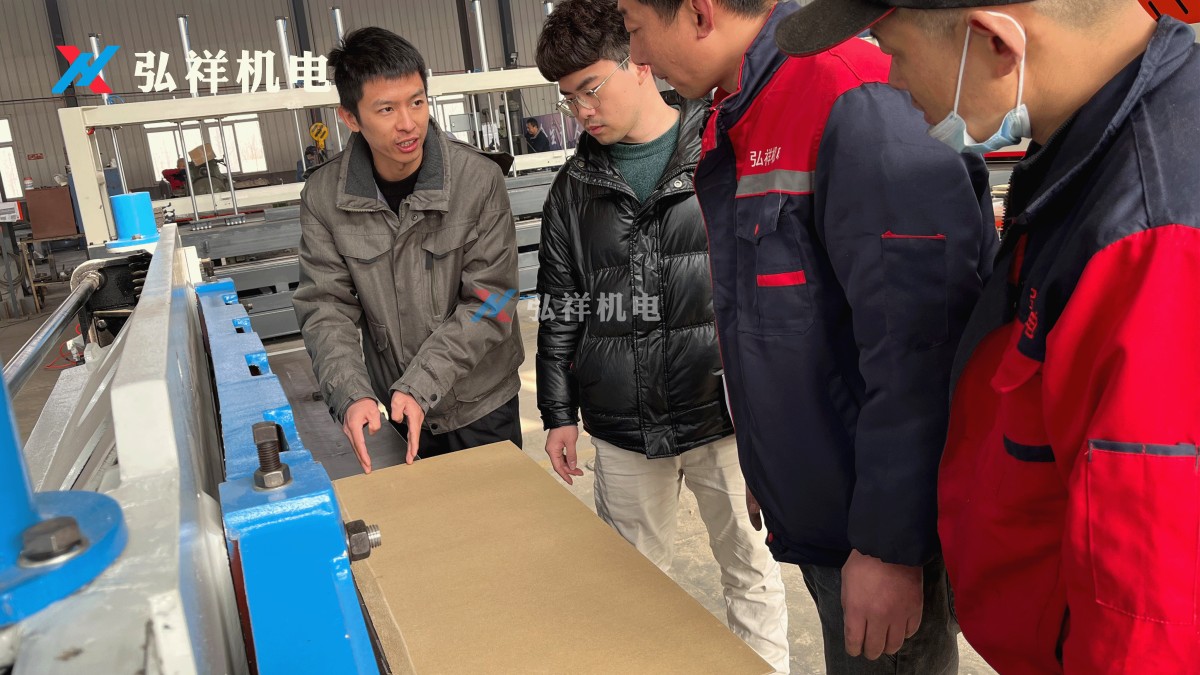

For projects requiring precision-cut components with oil-resistance certification, Gaomi Hongxiang Electromechanical Technology Co., LTD provides CNC-machined insulating parts compliant with IEC 60641-3. Their EVA molding process achieves ±0.08mm tolerance - suitable for 132-245kV range. When dealing with retrofit projects having non-standard clearances, their laminated wood solutions offer adjustable dielectric properties between 3.5-4.5kV/mm.

Decision Framework

- Verify dielectric tests used actual transformer oil samples, not laboratory substitutes

- Prioritize thermal class over price for load-cycling applications (>5 cycles/day)

- Require third-party certification for moisture regain claims above 65% RH

For transformer engineers evaluating insulation: The critical validation isn't the material's nominal strength, but its degradation rate under combined thermal-electrical stress matching your operating profile.

NAVIGATION

MESSAGE

Request A Quote?