0000-00

Electrical cardboard plays a pivotal role in transformer insulation, ensuring safety and efficiency in power distribution systems. As a key component in transformer insulation parts processing equipment for industrial use, selecting high-quality electrical cardboard is crucial for performance and longevity. This guide explores essential considerations when sourcing Transformer insulation parts processing equipment, comparing insulating cardboard brands, and evaluating laminated wood solutions. Whether you're a procurement specialist, technical evaluator, or project manager, understanding these factors will help you make informed decisions for your power transformer applications.

The Critical Function of Electrical Cardboard in Power Transformers

Electrical cardboard serves as the backbone of transformer insulation systems, providing dielectric strength and mechanical support between conductive components. In industrial-grade power transformers, this specialized material must withstand extreme electrical stresses while maintaining structural integrity under thermal cycling. The cellulose-based composition of premium electrical cardboard offers superior oil absorption properties, which is vital for liquid-immersed transformer applications. When evaluating transformer insulation parts processing equipment, engineers must consider how the machinery handles this delicate material during cutting, shaping, and assembly processes. The dimensional stability of electrical cardboard directly impacts the transformer's ability to maintain precise clearances between windings over decades of service.

Material Properties That Define Performance

High-performance electrical cardboard for transformers exhibits three critical characteristics: consistent density (typically 1.0-1.2 g/cm³), controlled moisture content (below 7%), and uniform thickness tolerance (±0.05mm). These parameters ensure predictable dielectric behavior when processing through transformer insulation parts processing equipment for laminated wood applications. The material's tensile strength (minimum 60 N/mm² in machine direction) prevents delamination during the winding process, while its thermal class rating (typically Class A up to 105°C) determines long-term reliability. Advanced manufacturers now incorporate nano-cellulose reinforcements to enhance mechanical properties without compromising the material's essential electrical insulation capabilities.

Evaluating Transformer Insulation Parts Processing Equipment

Selecting appropriate transformer insulation parts processing equipment requires careful analysis of both technical specifications and operational requirements. Industrial-grade machinery must accommodate the unique challenges posed by electrical cardboard, including its sensitivity to edge damage during cutting operations. Modern CNC-controlled systems offer significant advantages for processing transformer insulation components:

- Precision laser cutting systems minimize material waste while achieving tolerances within ±0.1mm

- Computerized thickness measurement ensures consistent quality across laminated wood insulation components

- Automated stacking and handling systems prevent contamination of delicate insulation surfaces

- Integrated quality control cameras detect surface imperfections invisible to the naked eye

Comparative Analysis of Insulating Cardboard Brands

When comparing different brands of insulating cardboard, procurement teams should establish evaluation criteria that align with transformer design requirements. Key comparison parameters include dielectric strength (kV/mm), porosity characteristics, and thermal aging performance. Reputable manufacturers provide certified test reports documenting:

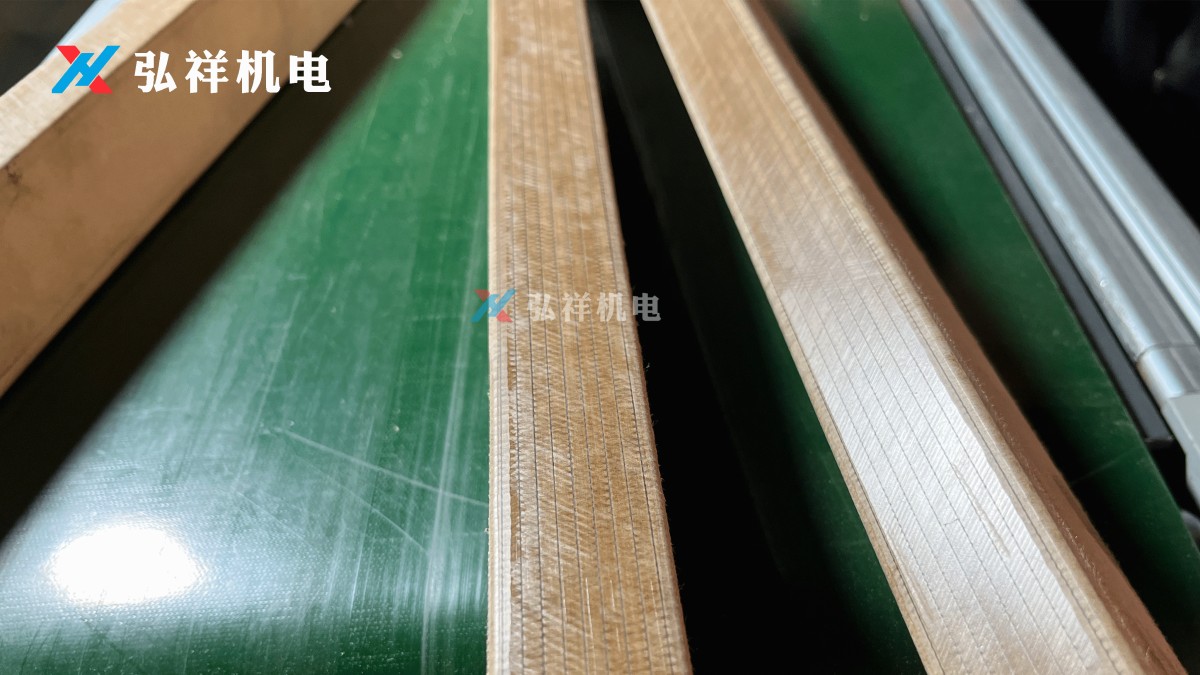

Advanced Solutions for Laminated Wood Insulation

Transformer insulation parts processing equipment for laminated wood requires specialized capabilities to handle the material's unique properties. Unlike standard electrical cardboard, laminated wood insulation combines cellulose layers with phenolic resins under high pressure, creating components with exceptional mechanical strength. Modern processing solutions incorporate:

- Pre-heating stations to reduce internal stresses before machining

- Diamond-coated tooling for extended service life when cutting resin-rich materials

- Dust extraction systems specifically designed for phenolic resin particles

- Temperature-controlled work environments to maintain dimensional stability

Global Sourcing Strategies for Insulation Components

When sourcing transformer insulation parts processing equipment, global buyers must balance technical capabilities with supply chain reliability. Leading manufacturers in the transformer insulation sector typically offer:

- Custom engineering support for specialized insulation configurations

- Localized service centers for equipment maintenance and spare parts

- Documentation packages including CE, UL, or other regional certifications

- Flexible production capacity to accommodate both large projects and emergency replacement orders

Future Trends in Transformer Insulation Technology

The transformer insulation industry is evolving to meet demands for higher efficiency and environmental sustainability. Emerging developments include bio-based resin systems for laminated wood components and AI-assisted quality control in electrical cardboard production. Modern transformer insulation parts processing equipment increasingly incorporates:

- Machine learning algorithms that optimize cutting patterns to minimize material waste

- IoT-enabled sensors for real-time monitoring of dielectric properties during processing

- Robotic arms with adaptive grippers for handling delicate insulation materials

- Integrated testing stations that verify electrical properties before component assembly

Conclusion and Next Steps

Selecting the right electrical cardboard and transformer insulation parts processing equipment requires careful consideration of technical specifications, manufacturing capabilities, and long-term performance requirements. From dielectric properties to processing precision, each factor contributes to the reliability and efficiency of power transformers in industrial applications. As global demand for energy-efficient power distribution grows, partnering with experienced manufacturers becomes increasingly critical.

Gaomi Hongxiang Electromechanical Technology Co., Ltd. offers comprehensive solutions for transformer insulation components, combining advanced manufacturing capabilities with global supply chain expertise. Our team provides technical consultation, customized equipment configurations, and ongoing support throughout your project lifecycle.

Ready to optimize your transformer insulation system? Contact our engineering team today to discuss your specific requirements and discover how our transformer insulation parts processing equipment can enhance your manufacturing operations. Request a detailed quotation or schedule a facility tour to see our capabilities firsthand.

NAVIGATION

MESSAGE

Request A Quote?