0000-00

Sourcing high-quality transformer insulation parts processing equipment requires careful evaluation of key factors. Whether you need bulk order solutions, EVA molding capabilities, or custom OEM services for electrical insulation components, selecting the right manufacturer is critical. This guide explores the top 5 considerations when procuring CNC transformer insulation parts processing equipment, especially when sourcing from China. From laminated wood processing to electrical insulation requirements, we'll help technical evaluators, procurement specialists, and project managers make informed decisions for their transformer manufacturing needs.

1. Equipment Precision and CNC Technology

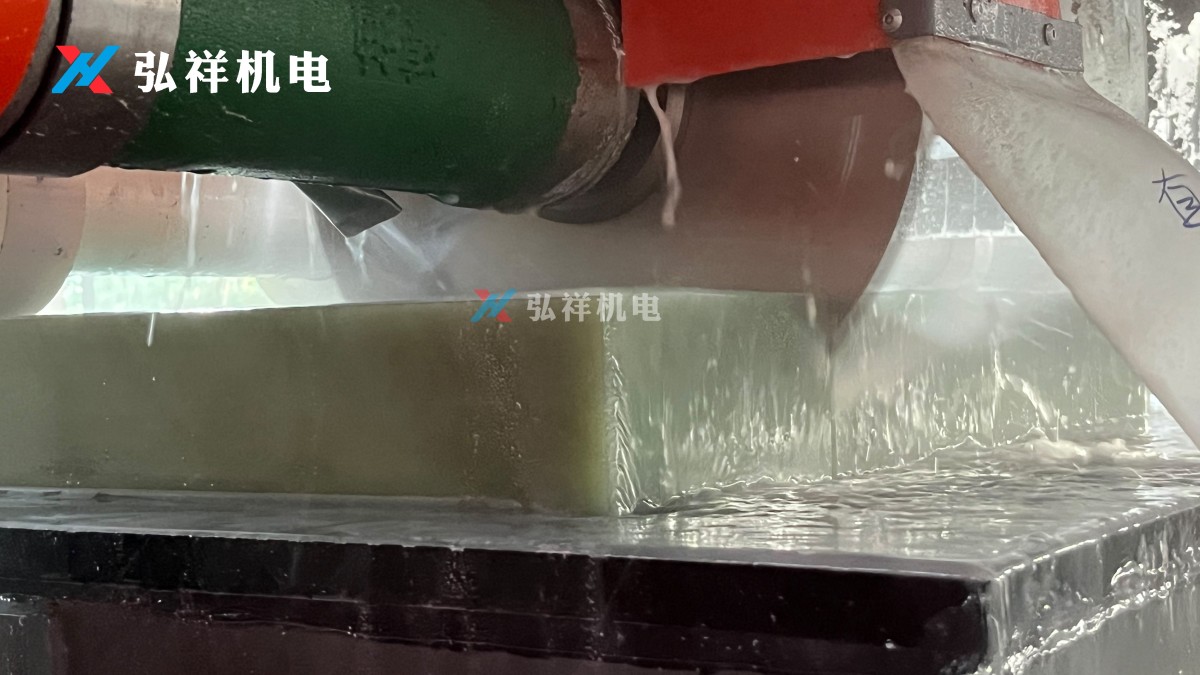

When sourcing transformer insulation parts processing equipment, precision is non-negotiable. CNC (Computer Numerical Control) technology plays a pivotal role in ensuring the accuracy and consistency of electrical insulation components. High-quality CNC machines can achieve tolerances as tight as ±0.01mm, which is essential for manufacturing transformer insulation parts that meet international standards like IEC 60076 and IEEE C57.12.00.

Key aspects to evaluate include:

- Multi-axis machining capabilities (3-axis, 4-axis, or 5-axis) for complex geometries in laminated wood and EVA molding

- Repeatability and positioning accuracy for bulk order production

- Compatibility with CAD/CAM software for custom transformer insulation parts processing

- Thermal stability features to prevent material deformation during electrical insulation component manufacturing

Leading manufacturers in China now integrate AI-assisted quality control systems that automatically detect and compensate for tool wear, ensuring consistent output even for large-volume orders.

2. Material Processing Capabilities

Transformer insulation parts processing equipment must handle diverse materials with varying properties. The machinery should demonstrate proven performance with:

- Electrical insulating cardboard (NOMEX, pressboard)

- Insulating laminated wood (hardwood composites)

- EVA (Ethylene-Vinyl Acetate) for molding applications

- Composite materials for high-voltage applications

For OEM service providers, the equipment should offer flexible tooling systems that can quickly adapt to different material specifications. Look for features like automatic tool changers (12+ stations preferred) and material-specific cutting parameters that can be stored and recalled for repeat orders.

3. Production Capacity and Scalability

When evaluating transformer insulation parts processing equipment for bulk order fulfillment, consider both current needs and future growth. Key metrics include:

For manufacturers sourcing from China, verify the supplier's ability to support production scaling through modular equipment designs that allow for easy capacity expansion without complete system overhauls.

4. Quality Assurance and Certification

Reliable transformer insulation parts processing equipment manufacturers should provide comprehensive quality documentation and hold relevant certifications:

- ISO 9001:2015 for quality management systems

- CE certification for European market compliance

- UL certification for North American markets

- Material-specific test reports (e.g., dielectric strength tests for electrical insulation components)

Advanced manufacturers now incorporate in-process quality monitoring systems that use machine vision and laser measurement to verify dimensional accuracy of each processed part, particularly critical for custom transformer insulation parts processing equipment applications.

5. After-Sales Support and Technical Training

The total cost of ownership extends beyond the initial purchase. Evaluate the manufacturer's support infrastructure:

- Availability of spare parts for CNC transformer insulation parts processing equipment

- On-site installation and commissioning services

- Operator and maintenance training programs

- Remote diagnostic capabilities for troubleshooting

- Warranty terms (minimum 18 months recommended)

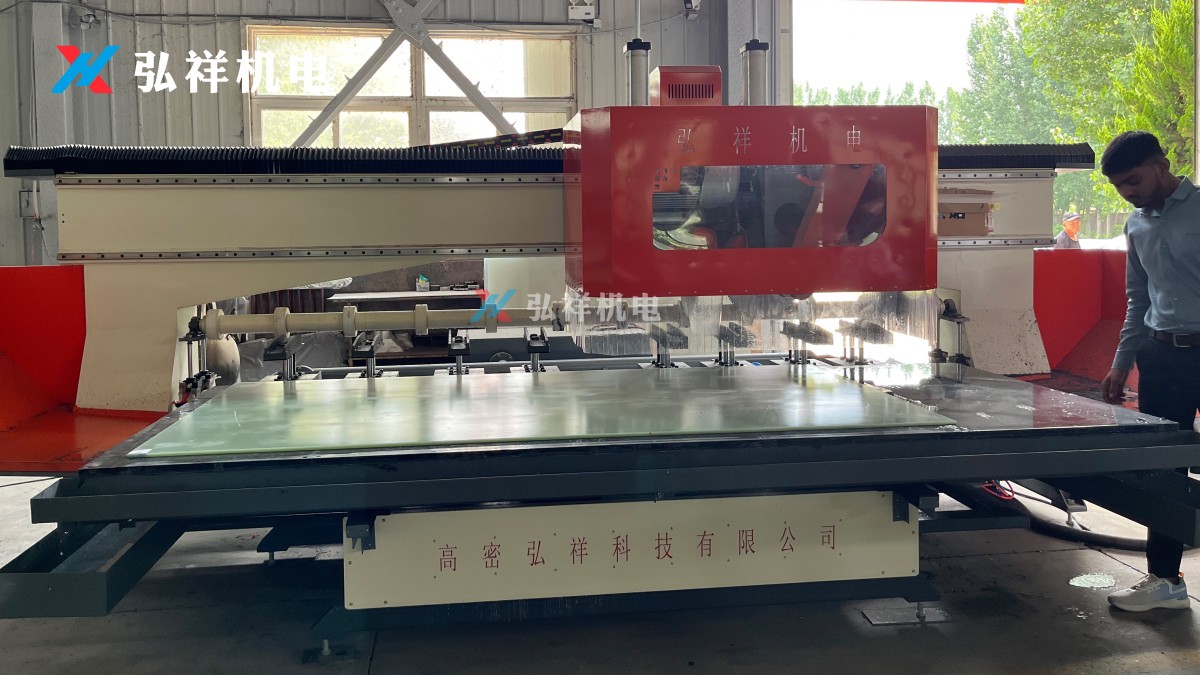

Leading Chinese manufacturers like Gaomi Hongxiang Electromechanical Technology Co., Ltd. now offer augmented reality (AR) assisted maintenance, allowing technicians to access equipment manuals and troubleshooting guides through smart glasses during service calls.

Conclusion and Next Steps

Selecting the right transformer insulation parts processing equipment requires balancing technical specifications, material requirements, production needs, and long-term support considerations. Whether you require equipment for EVA molding, laminated wood processing, or custom electrical insulation components, prioritizing these five factors will ensure you make an informed procurement decision.

For organizations sourcing transformer insulation parts processing equipment from China, verify the manufacturer's experience with international projects and their ability to provide OEM service with documentation in your required language. Request sample processing runs using your specific materials to validate performance claims before committing to bulk orders.

Ready to source high-quality transformer insulation parts processing equipment? Contact our engineering team today for personalized recommendations and competitive quotes tailored to your specific requirements.

NAVIGATION

MESSAGE

Request A Quote?