0000-00

Oil gap spacer plays an important role in power equipment such as transformer, which is mainly used to fill the oil gap between the windings to provide insulation and support.

- Definitions and Functions

Oil gap spacer is a block-shaped object made of insulating material, which is placed in the oil gap between transformer windings. Its main functions include:

Insulation function: Oil gap spacer has good insulation performance, which can effectively isolate windings with different potentials, prevent current leakage and short circuit, and ensure the safe operation of transformer.

Supporting function: The oil gap spacer also provides necessary support for the winding, maintaining its shape and position stability to prevent deformation or displacement during operation.

2. Types and Structure

The oil gap spacer comes in various types and structures to meet different transformer design and operational requirements.

Common types include: classified by material, such as rubber oil gap spacers and plastic oil gap spacers. Different materials provide varying insulation and aging resistance properties.

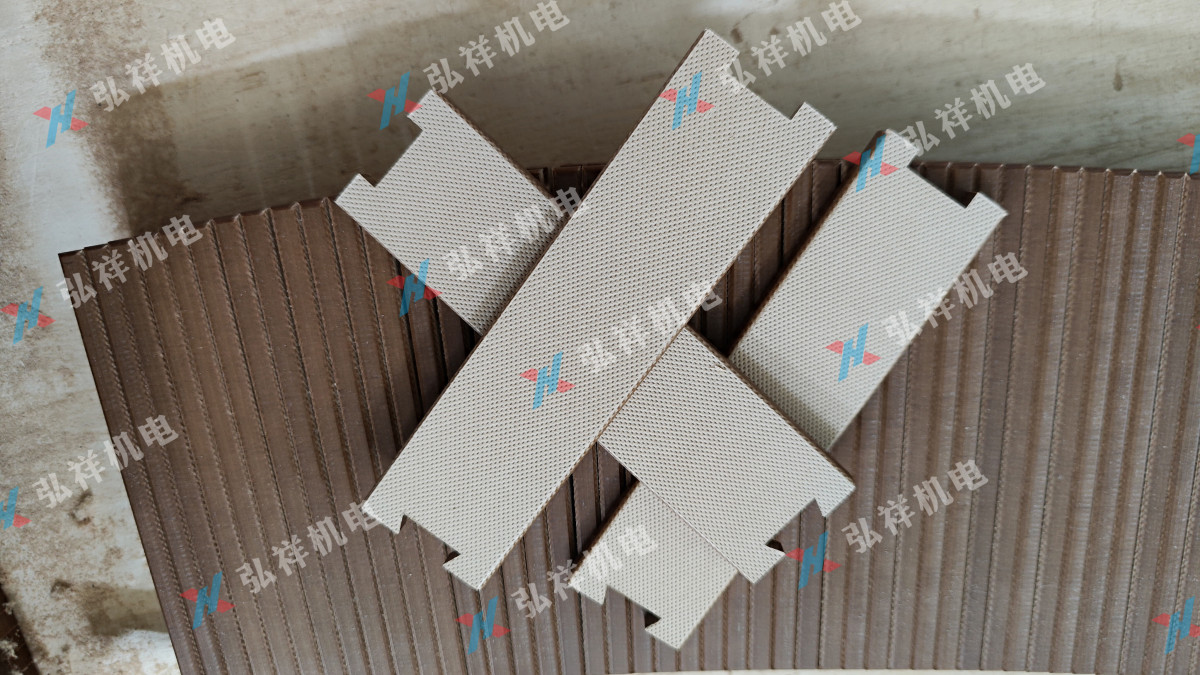

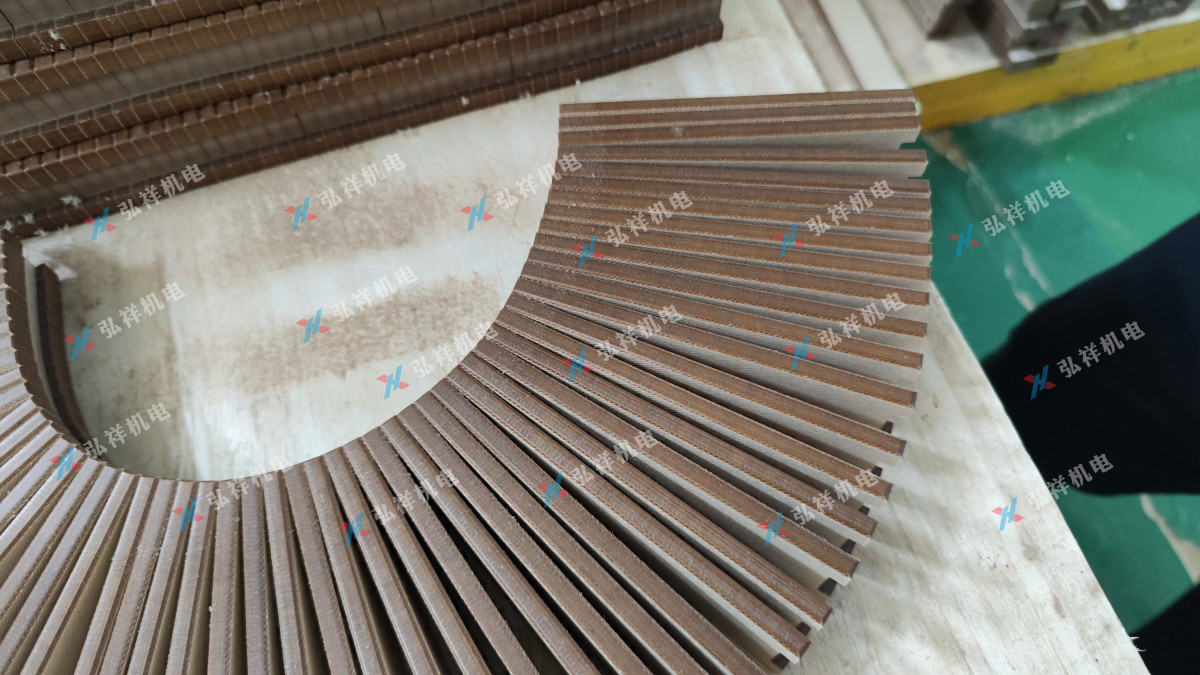

Shape-based classification: Common shapes include rectangular, circular, and I-shaped, along with specially designed variants like dovetail grooves and T-shaped grooves to meet specific installation requirements.

Composite structure: Some oil gap blocks are designed with composite structure, such as forming the insulation layer together with the paper ring, and improving the stability and insulation performance through the design of the limit groove and rubber layer.

3. Design and Application

The design of oil gap spacer should consider many factors, such as the voltage level of transformer, winding structure, oil gap size, etc. In practice, the oil gap spacer should be processed and installed according to the specific design drawings and requirements.

Processing methods: Oil gap spacer blocks can be manufactured through various techniques including punching and milling. With the increasing voltage levels and quality standards of power transformers, traditional punching processes have become inadequate. Consequently, advanced equipment such as oil gap spacer block forming machines has been introduced. These machines utilize single-pass milling to enhance both product quality and production efficiency.

Installation and Adjustment: When installing the oil gap spacer, ensure it fits tightly and is positioned correctly against the winding. Adjustments and optimizations may be required during installation to achieve optimal performance.

4. Importance

The importance of oil gap spacer in transformer is self-evident. Good insulation performance and support function are crucial to ensure the safe and stable operation of transformer. If oil gap spacer has defects or improper installation, it may lead to partial discharge, creepage, and other phenomena, which will affect the insulation performance and service life of transformer.

In conclusion, the oil gap spacer is an indispensable component in power equipment such as transformers. Through reasonable design, processing, and proper installation and adjustment, it can fully perform its function, providing strong support for the safe and stable operation of power equipment.

5. Conclusion

In summary, oil gap shims play a vital role in power equipment such as transformers, serving as a key factor in ensuring safe and stable operation. With the rapid development of the power industry and continuous advancements in power equipment technology, the quality and performance requirements for oil gap shims will continue to rise. Therefore, when designing and manufacturing oil gap shims, it is essential to fully consider the operational conditions and requirements of the equipment, ensuring the shims meet practical needs and deliver optimal performance.

NAVIGATION

MESSAGE

Request A Quote?